Patents

Literature

111 results about "Quantum size effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quantum size effect. Whereby the electrical properties of an object are altered with reductions to particle size.

Nanostructured bulk thermoelectric material

ActiveUS20060118158A1High quality factorImprove mechanical propertiesThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsNanowire

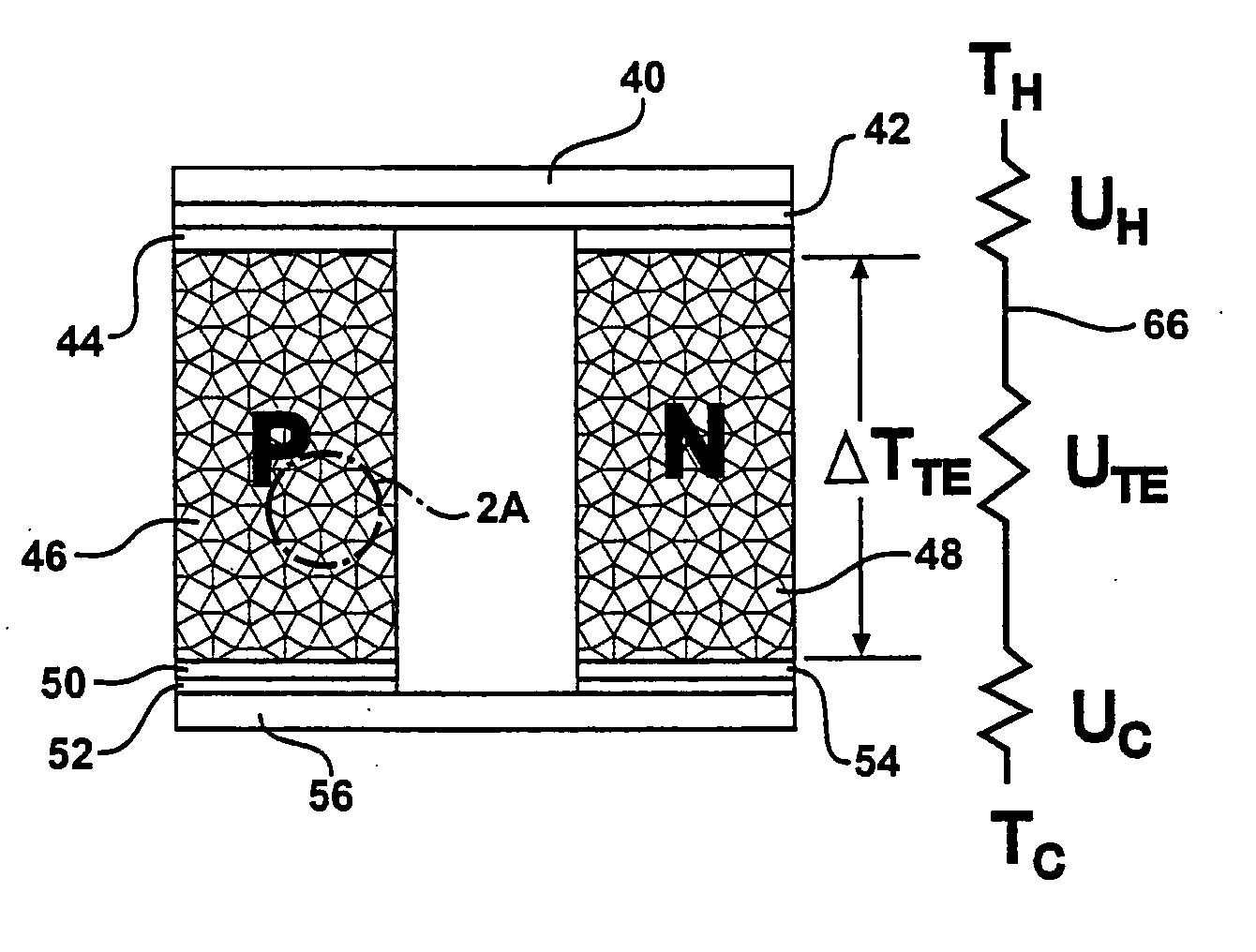

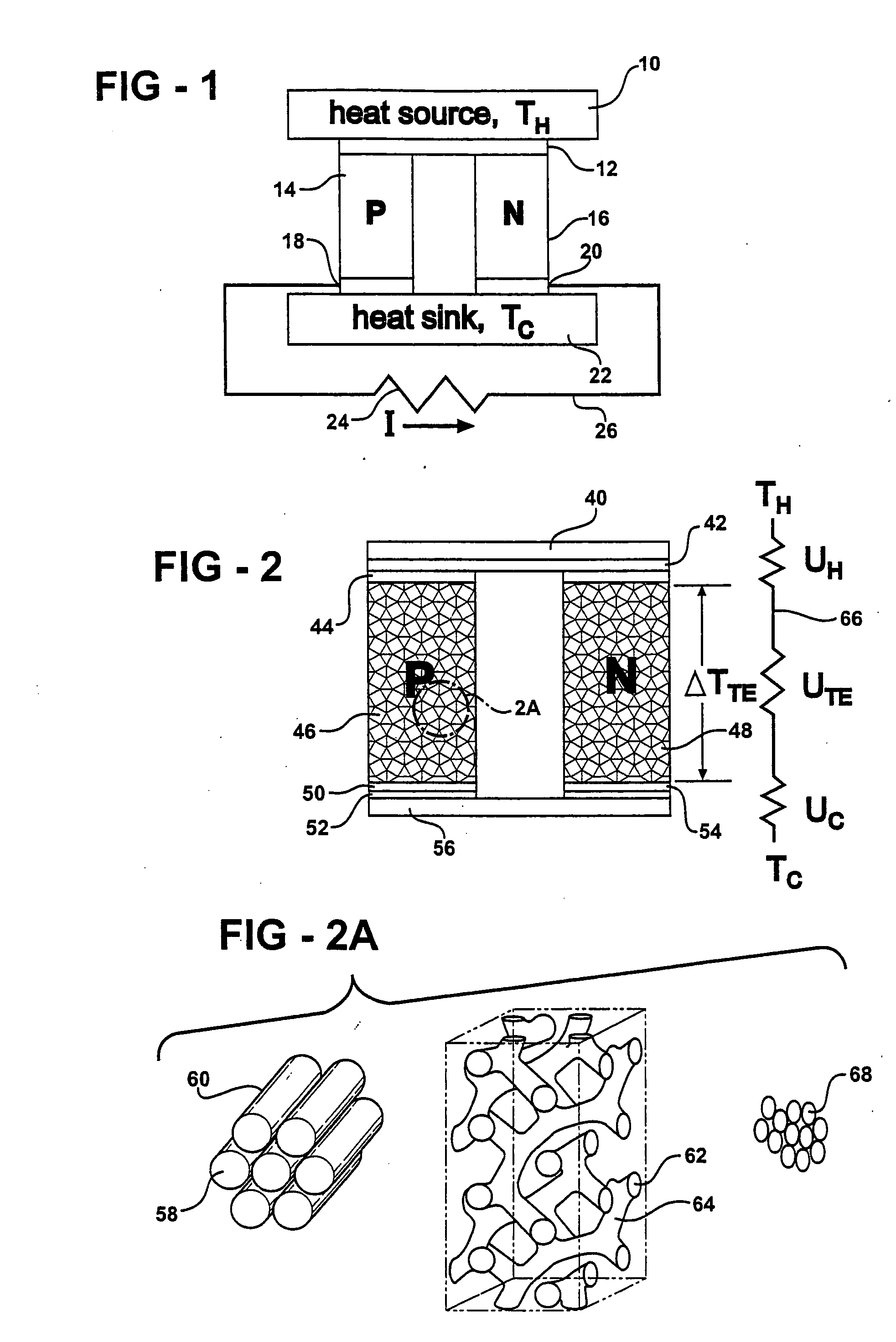

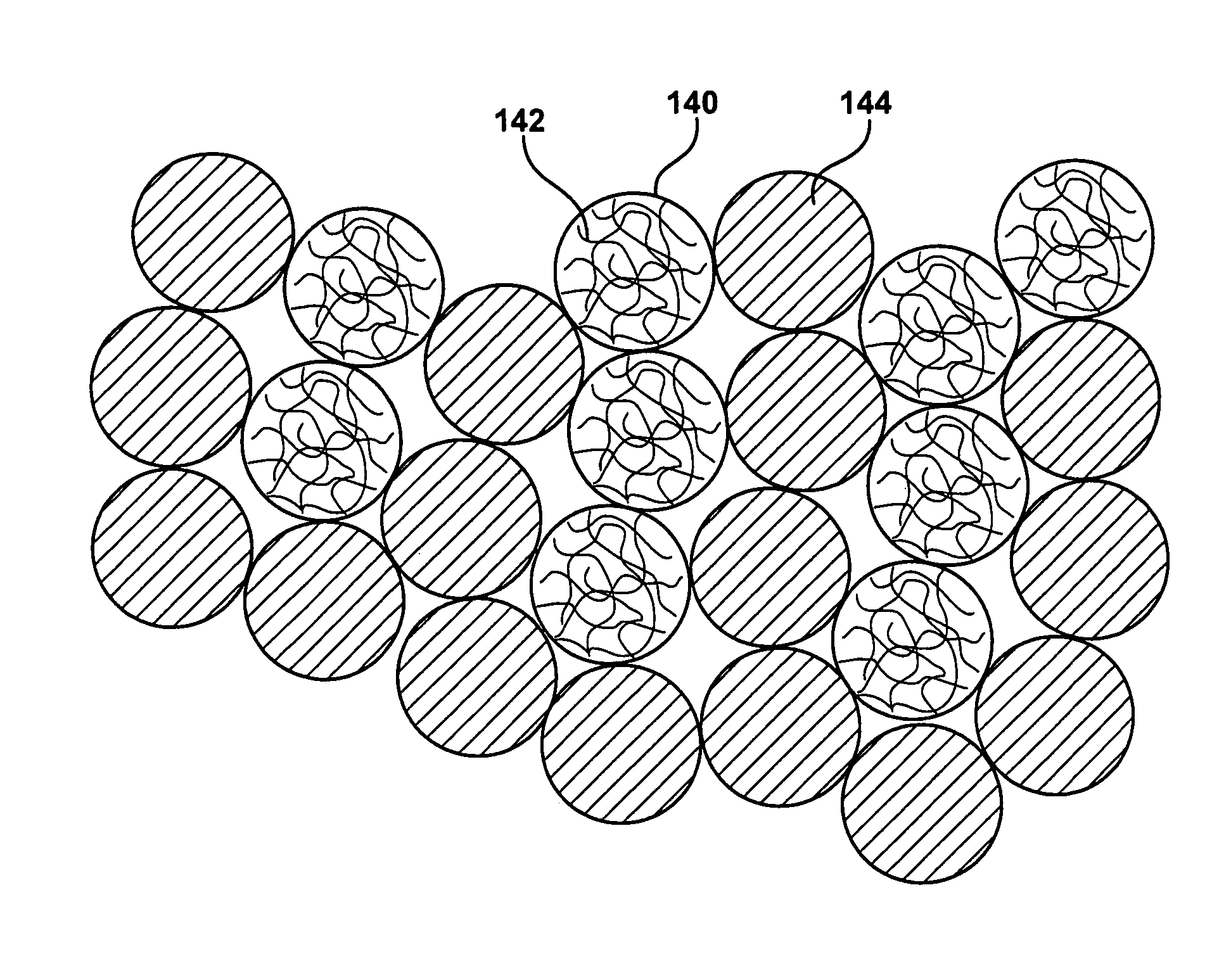

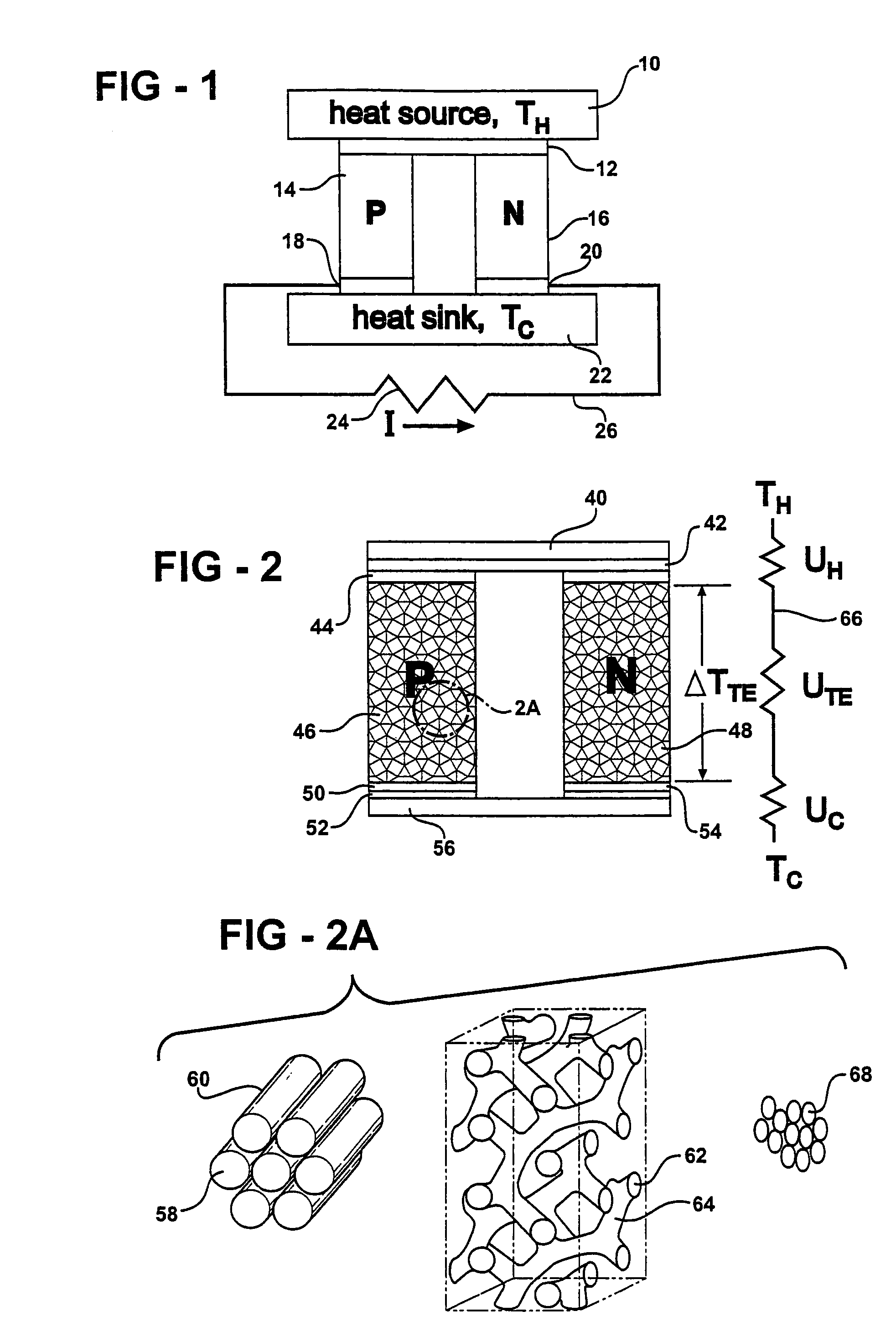

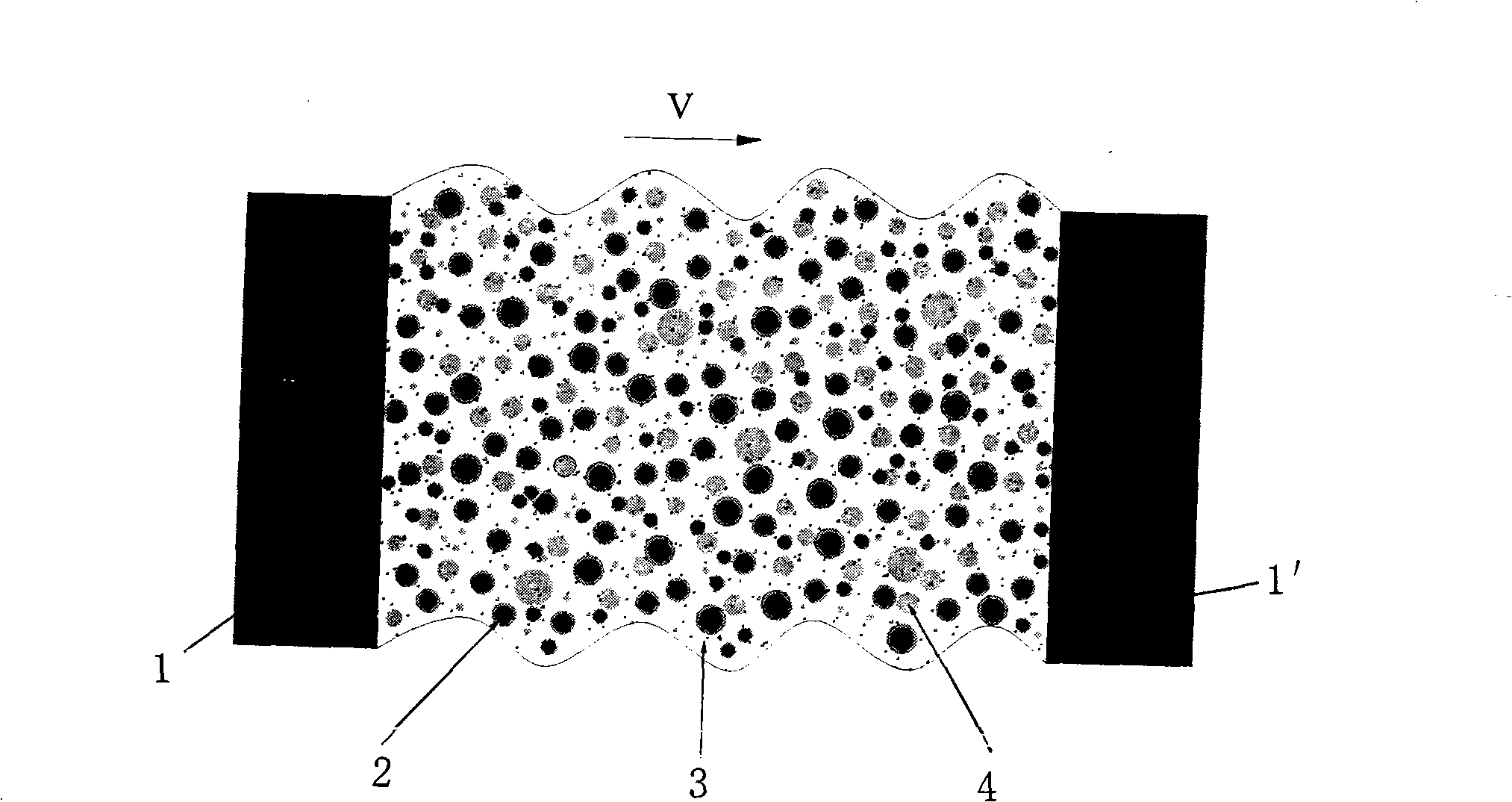

A thermoelectric material comprises two or more components, at least one of which is a thermoelectric material. The first component is nanostructured, for example as an electrically conducting nanostructured network, and can include nanowires, nanoparticles, or other nanostructures of the first component. The second component may comprise an electrical insulator, such as an inorganic oxide, other electrical insulator, other low thermal conductivity material, voids, air-filled gaps, and the like. Additional components may be included, for example to improve mechanical properties. Quantum size effects within the nanostructured first component can advantageously modify the thermoelectric properties of the first component. In other examples, the second component may be a thermoelectric material, and additional components may be included.

Owner:TOYOTA MOTOR CO LTD +1

Nanostructured bulk thermoelectric material

ActiveUS7309830B2High quality factorImprove mechanical propertiesThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsNanowire

A thermoelectric material comprises two or more components, at least one of which is a thermoelectric material. The first component is nanostructured, for example as an electrically conducting nanostructured network, and can include nanowires, nanoparticles, or other nanostructures of the first component. The second component may comprise an electrical insulator, such as an inorganic oxide, other electrical insulator, other low thermal conductivity material, voids, air-filled gaps, and the like. Additional components may be included, for example to improve mechanical properties. Quantum size effects within the nanostructured first component can advantageously modify the thermoelectric properties of the first component. In other examples, the second component may be a thermoelectric material, and additional components may be included.

Owner:TOYOTA MOTOR CO LTD +1

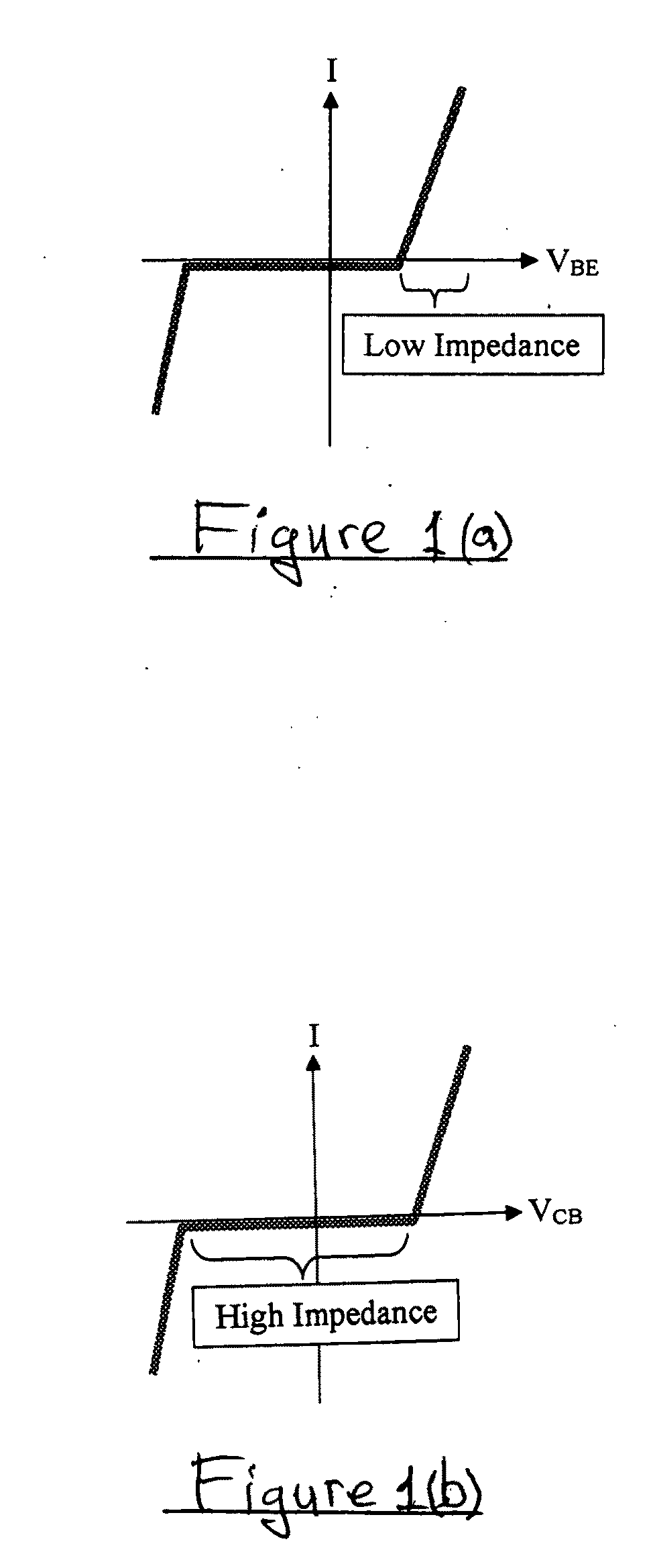

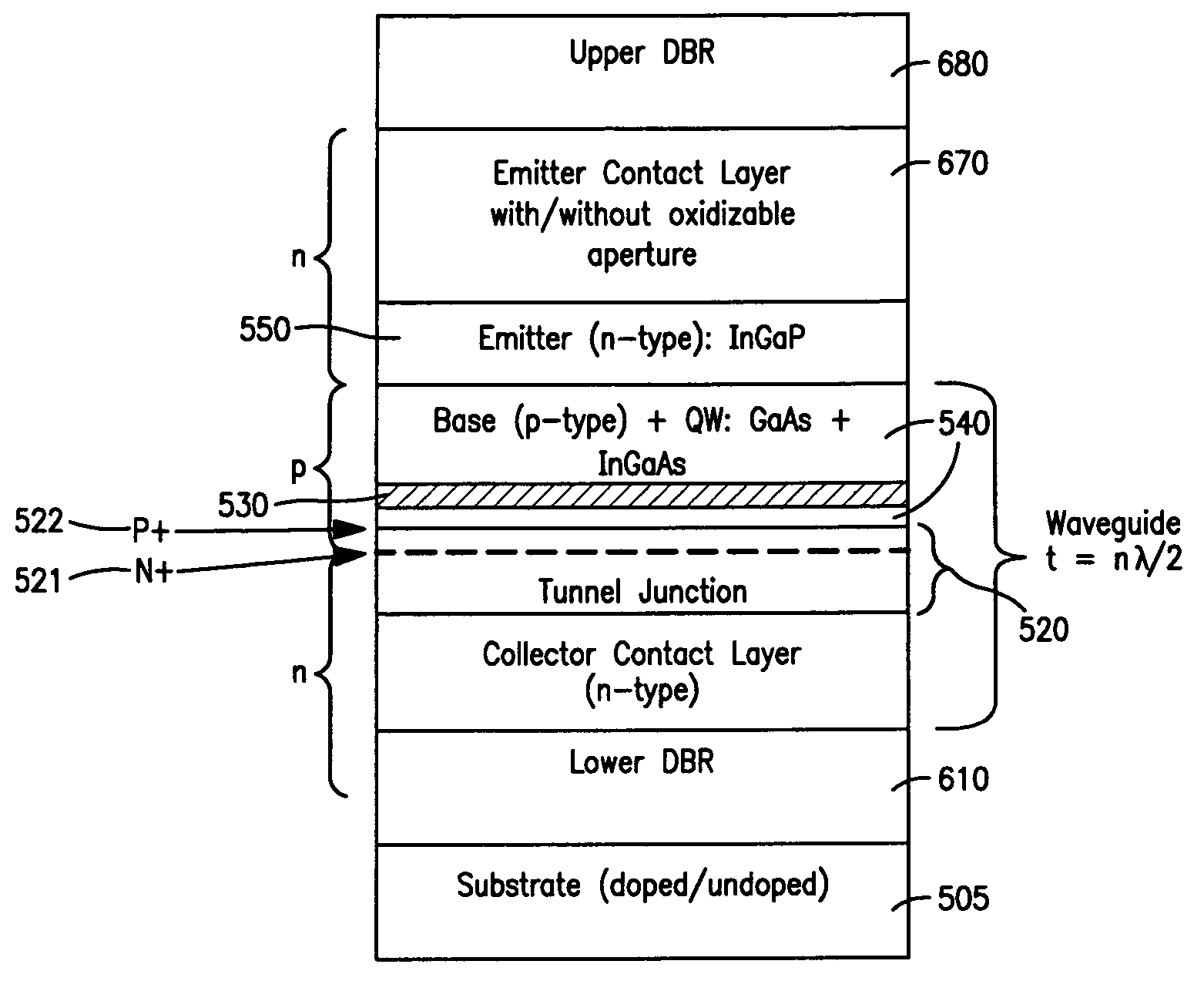

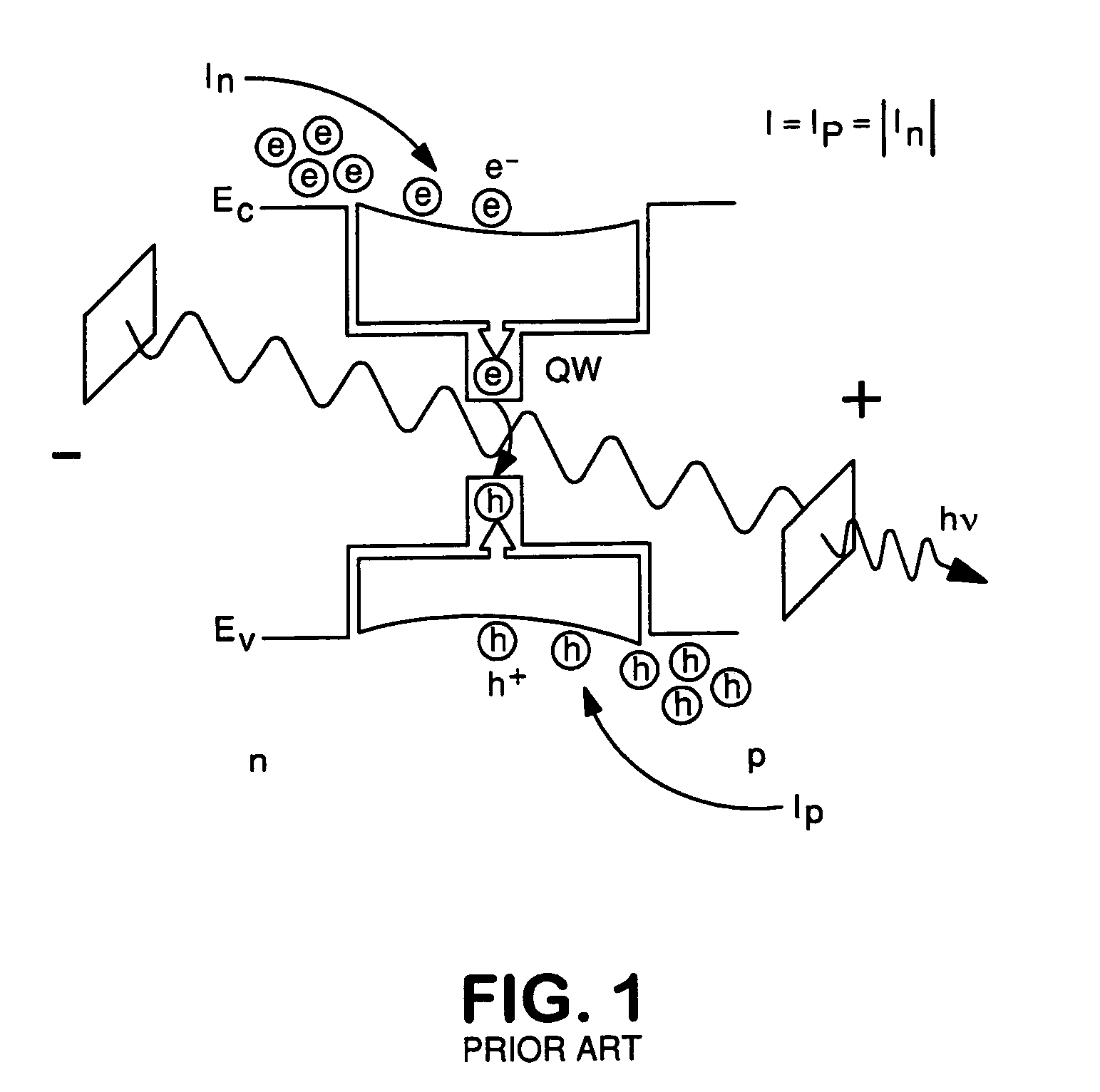

Light emitting and lasing semiconductor devices and methods

ActiveUS20100034228A1Inhibit injectionAvoid transportLaser detailsSemiconductor lasersElectron flowQuantum size effect

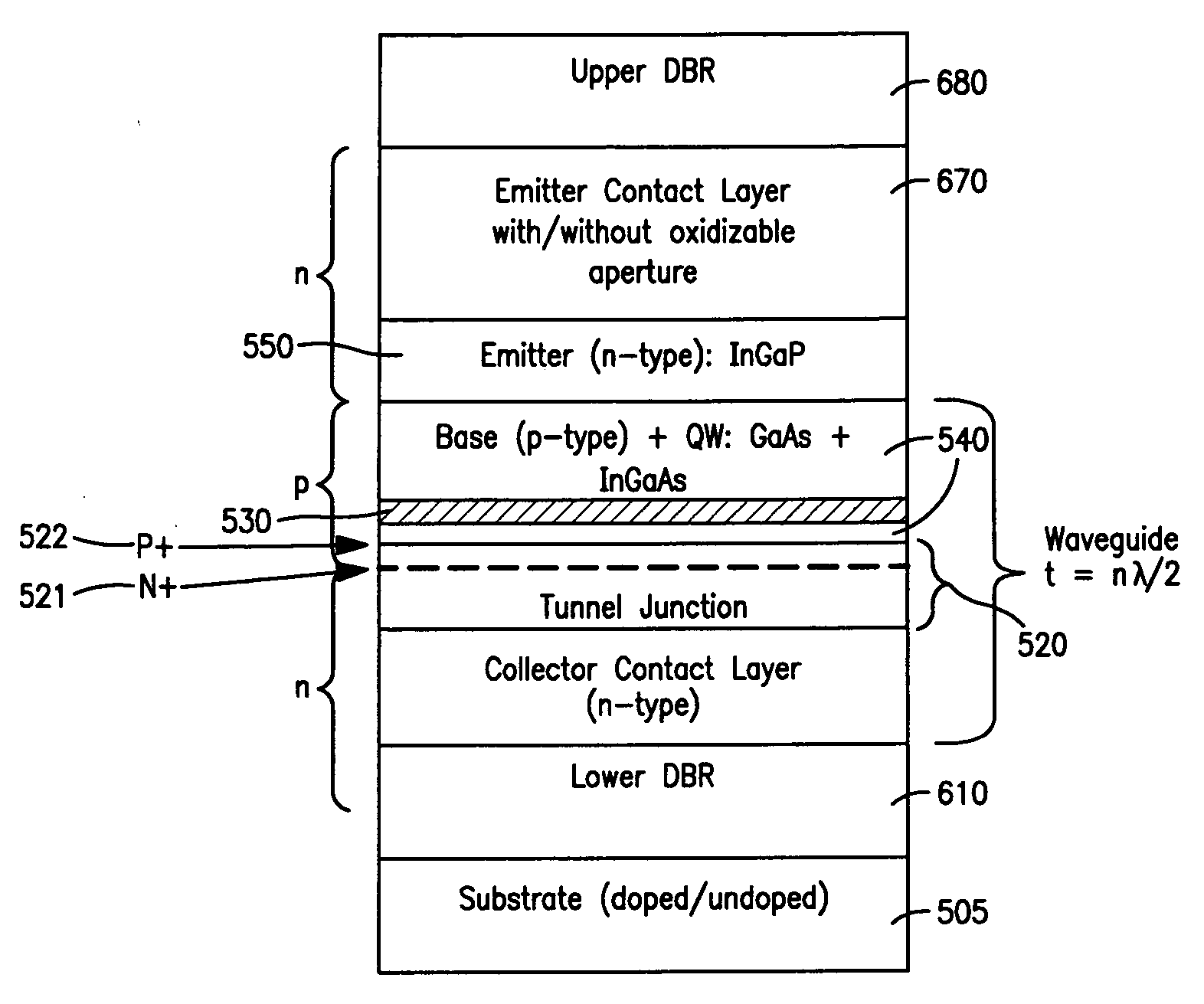

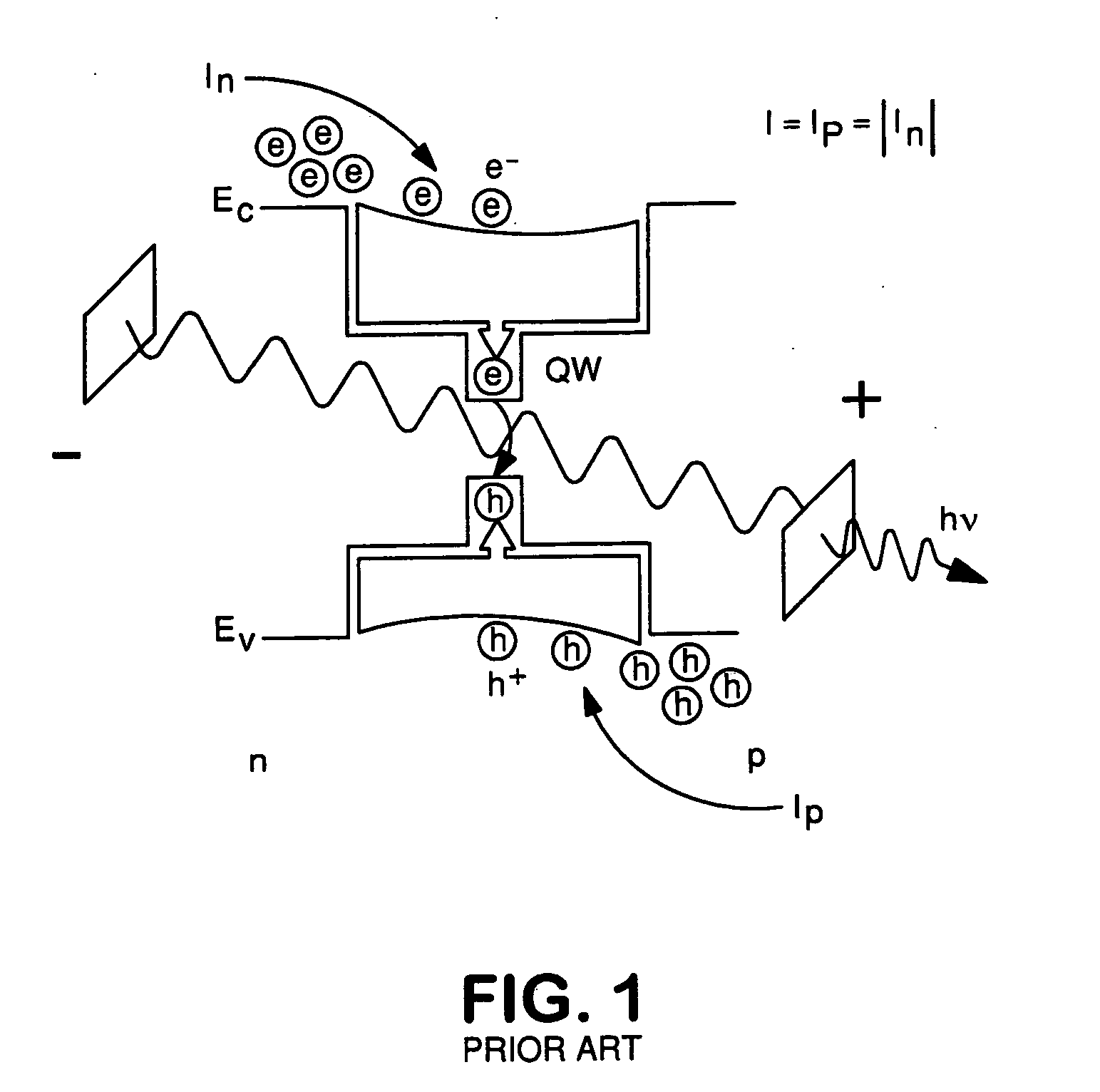

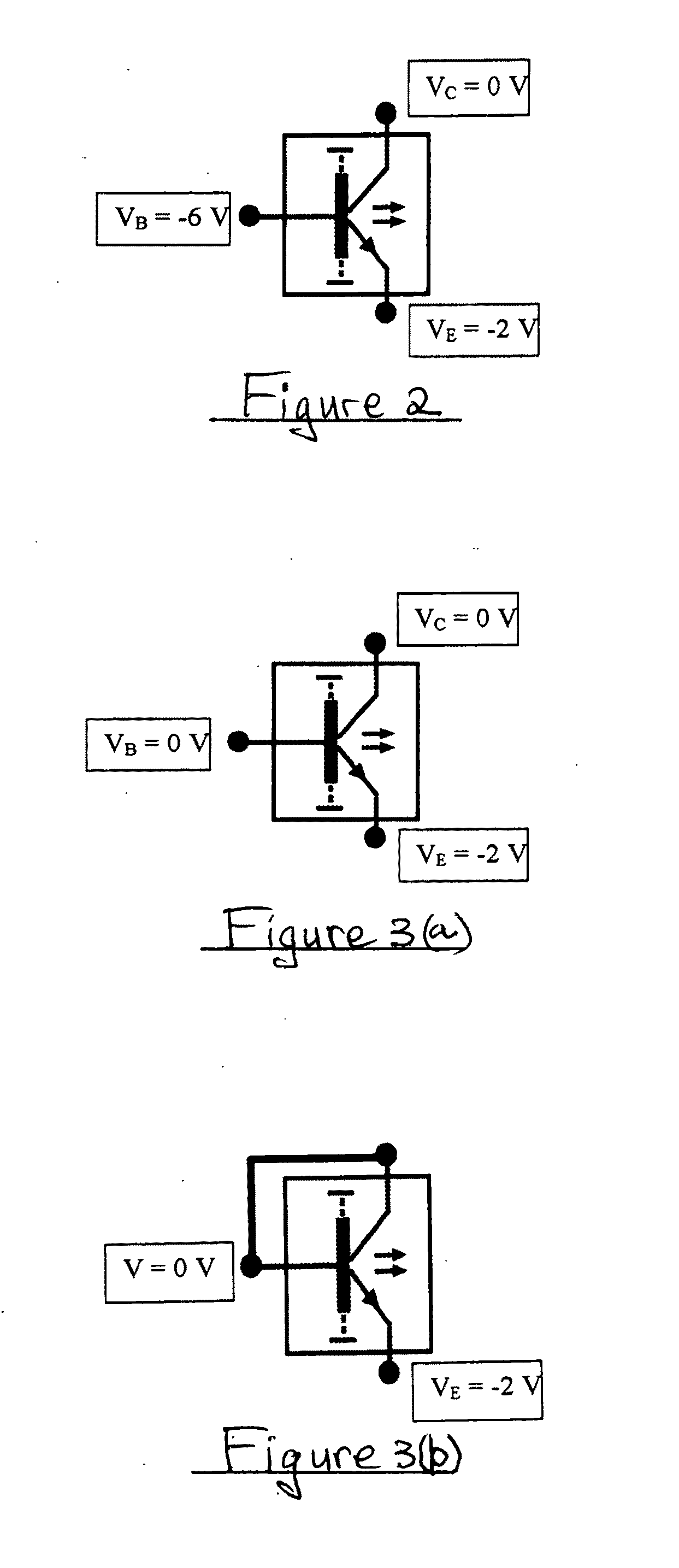

A two terminal semiconductor device for producing light emission in response to electrical signals, includes: a terminal-less semiconductor base region disposed between a semiconductor emitter region and a semiconductor collector region having a tunnel junction adjacent the base region; the base region having a region therein exhibiting quantum size effects; an emitter terminal and a collector terminal respectively coupled with the emitter region and the collector region; whereby application of the electrical signals with respect to the emitter and collector terminals, causes light emission from the base region. Application of the electrical signals is operative to reverse bias the tunnel junction. Holes generated at the tunnel junction recombine in the base region with electrons flowing into the base region, resulting in the light emission. The region exhibiting quantum size effects is operative to aid recombination.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

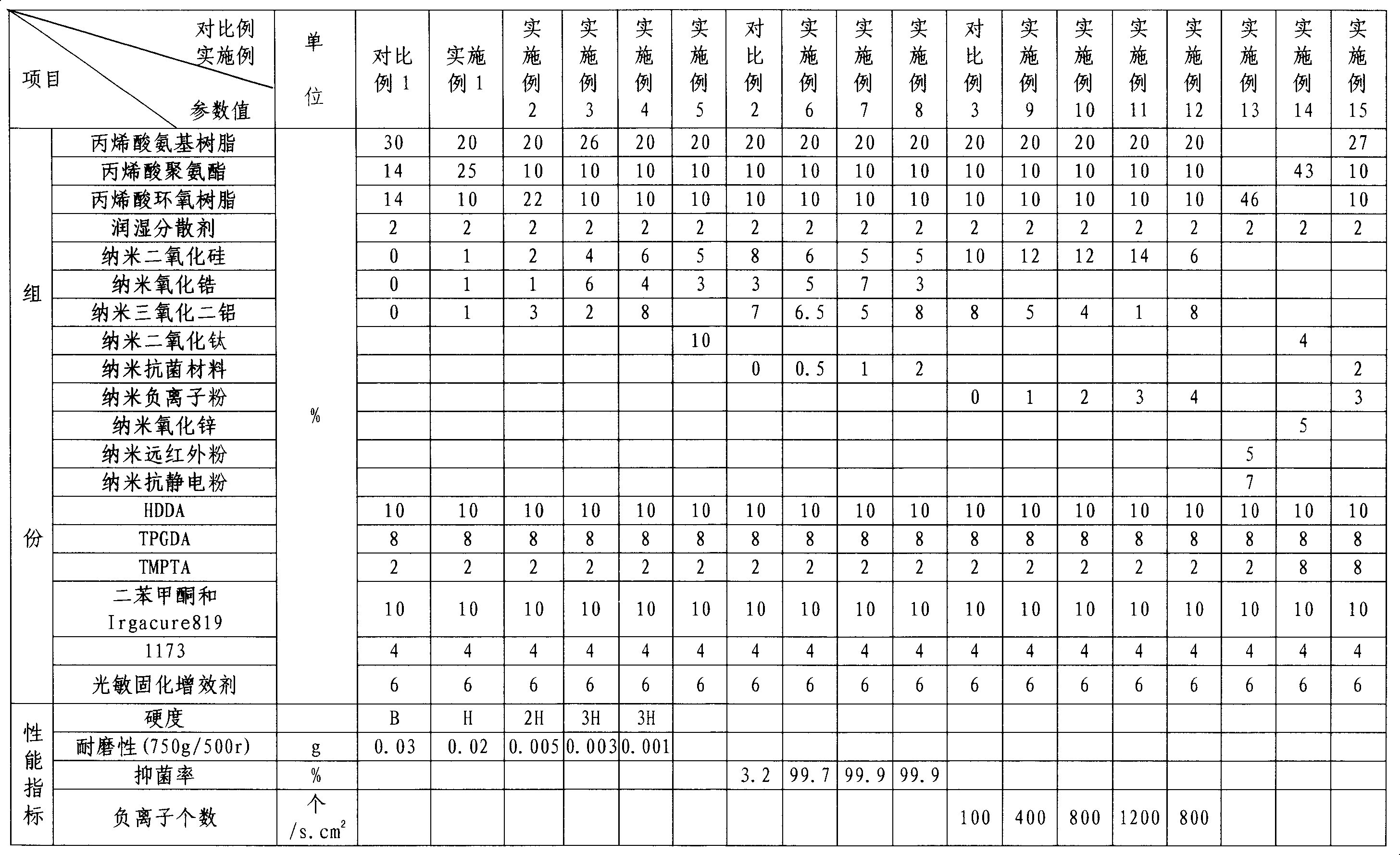

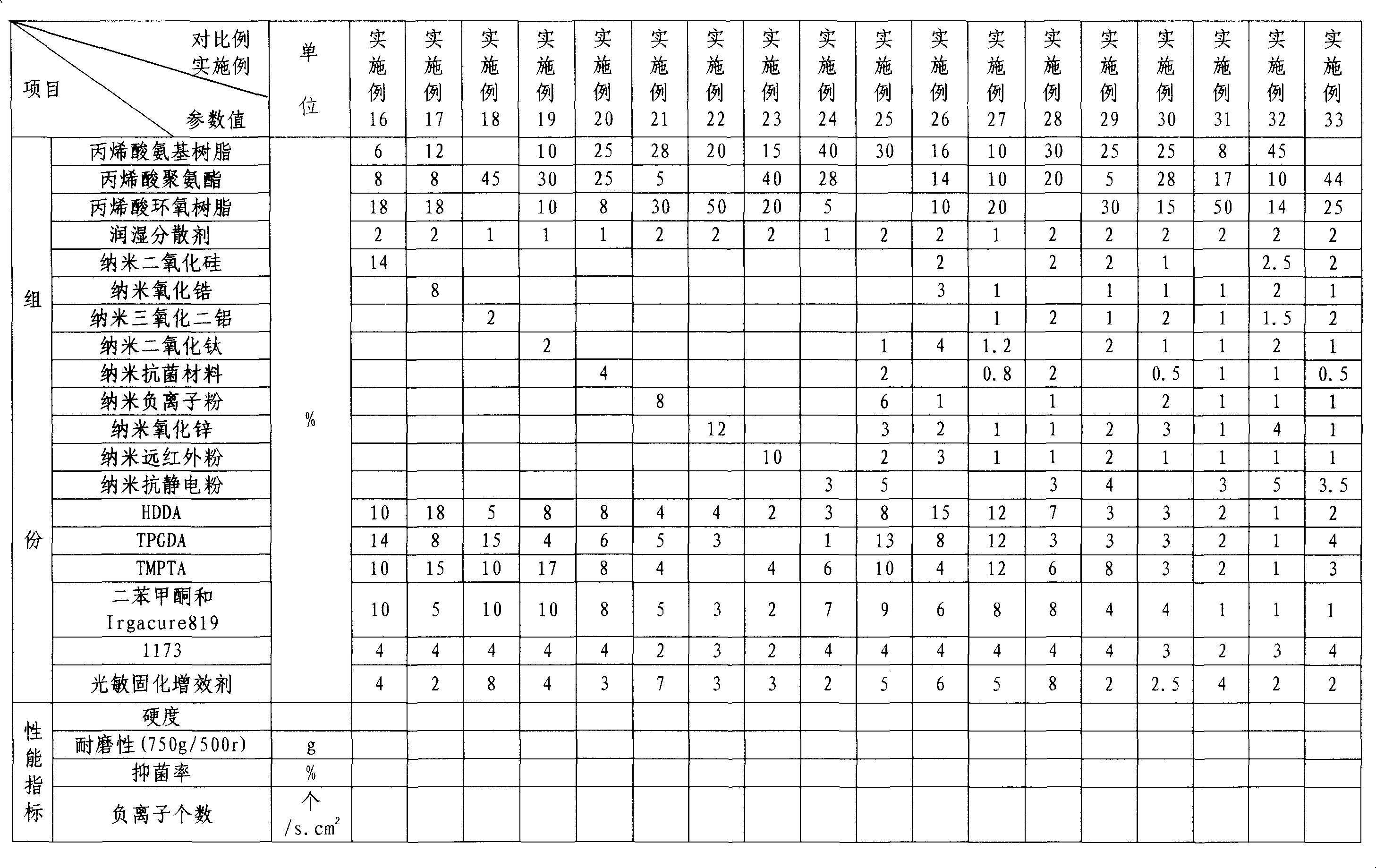

Nano technology modified ultraviolet solidified woodware paint

InactiveCN1554717AImprove wear resistanceHigh surface hardnessPaints with biocidesPolyurea/polyurethane coatingsEpoxyUltraviolet

The modified ultraviolet cured woodenware paint consists of one or several of nano silica, zirconia, titania, zinc oxide, negative ion powder, antibiotic material, far infrared powder, antistatic powder and alumina in 0.3-20 wt% and active oligomer comprisnig acrylic epoxy resin, acrylic polyurethane and acrylic amino resin in 30-76 wt%. The modified ultraviolet cured woodenware paint has the small size effect, surface effect, quantum size effect and macroscopic quantum tunnel characteristic of nano material, so that it has high antiwear property, hgih surface hardness, high toughness, high cracking resistance and many other advantages.

Owner:南京海泰纳米材料有限公司

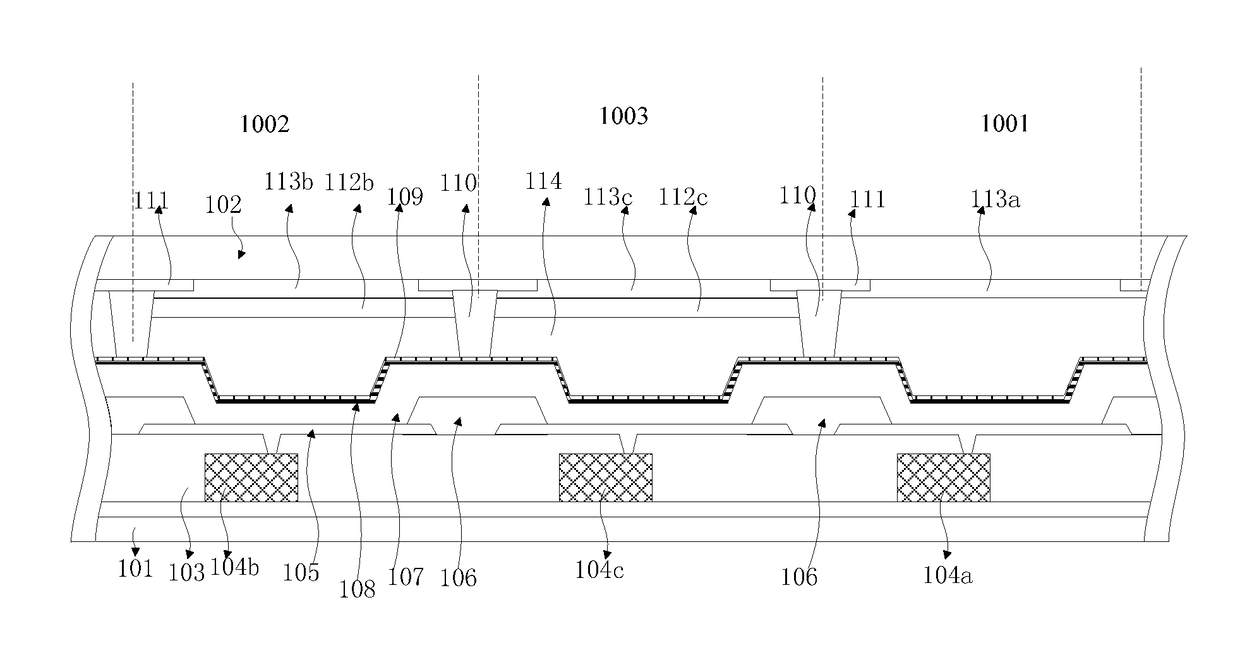

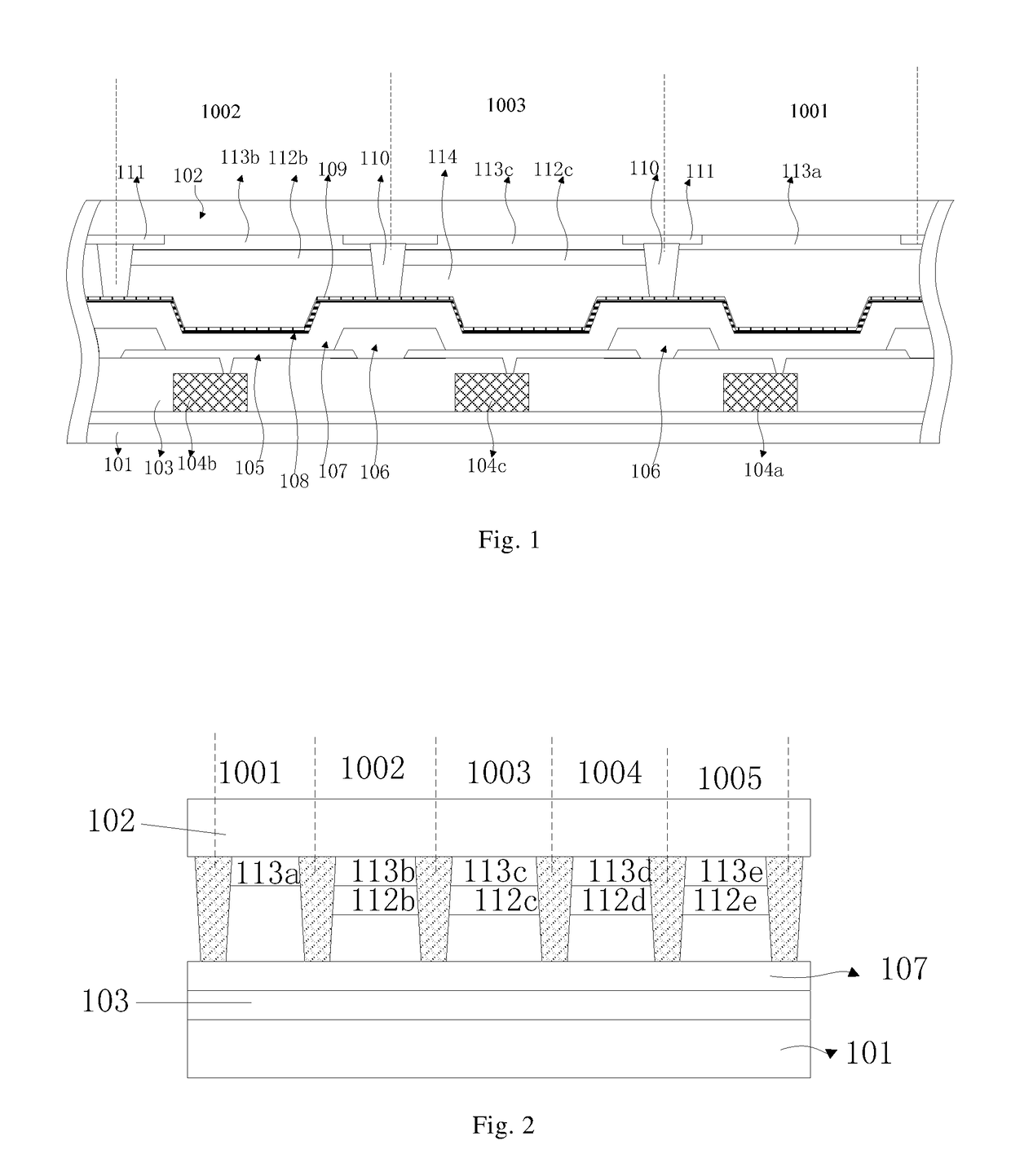

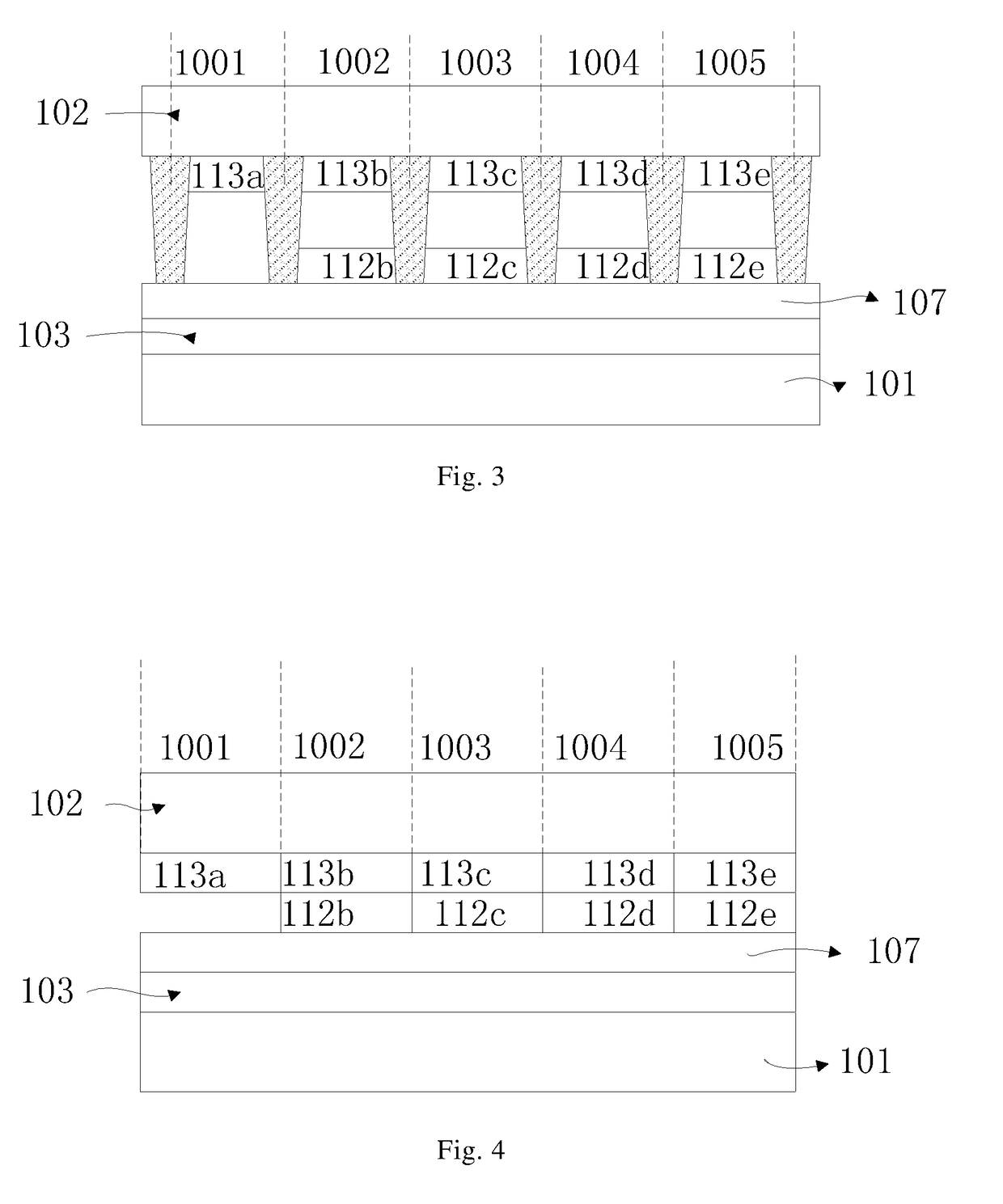

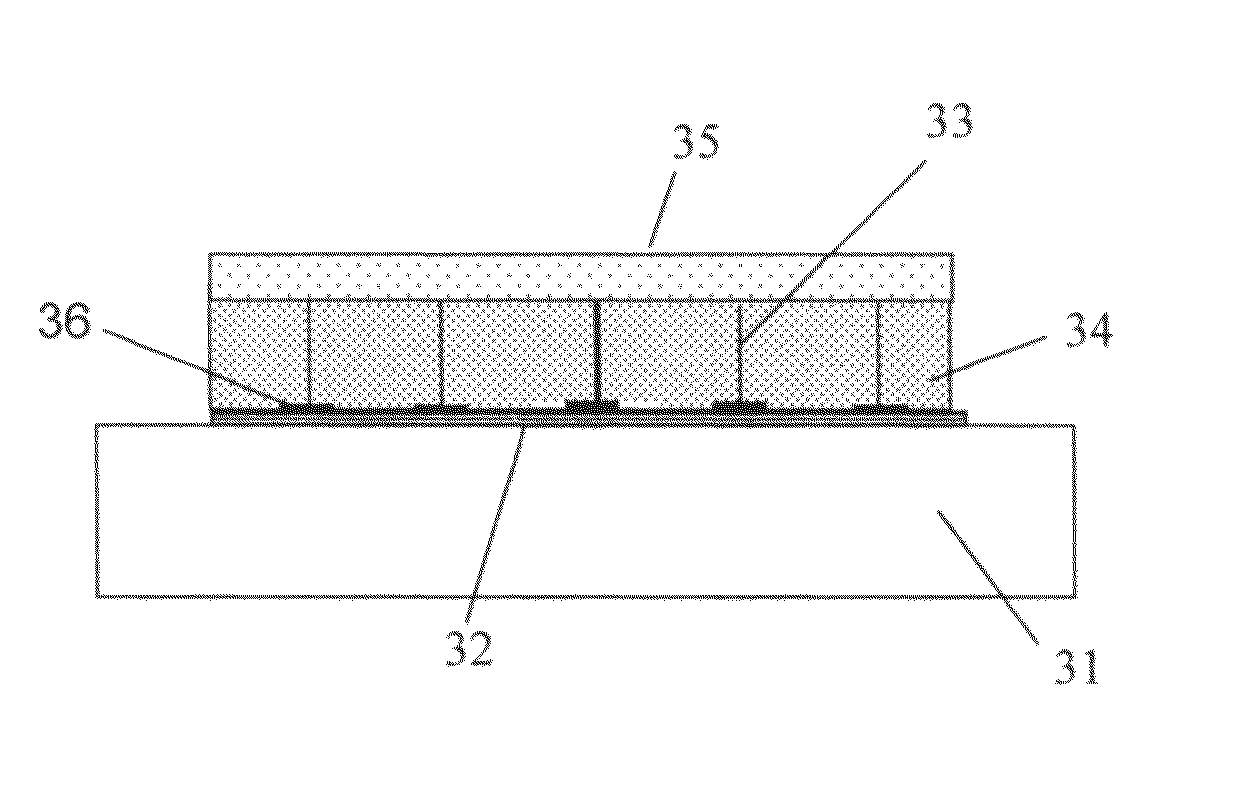

Organic light emitting display panel and manufacturing method thereof, and display device

ActiveUS20170179438A1Increase profitIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceQuantum size effect

The invention provides an organic light emitting display panel and a manufacturing method thereof, and a display device. In the organic light emitting display panel and the manufacturing method thereof, and the display device of the invention, since a quantum material layer exhibiting quantum size effects is arranged on a side of a color filter substrate close to an array substrate or on a side of an array substrate close to a color filter substrate, and can convert a part of light emitted thereinto from the organic light emitting unit into light with a same color as that of a corresponding sub-pixel, the utilization rate of light emitted from the organic light emitting unit is increased, brightness is improved, and power consumption is reduced.

Owner:BOE TECH GRP CO LTD

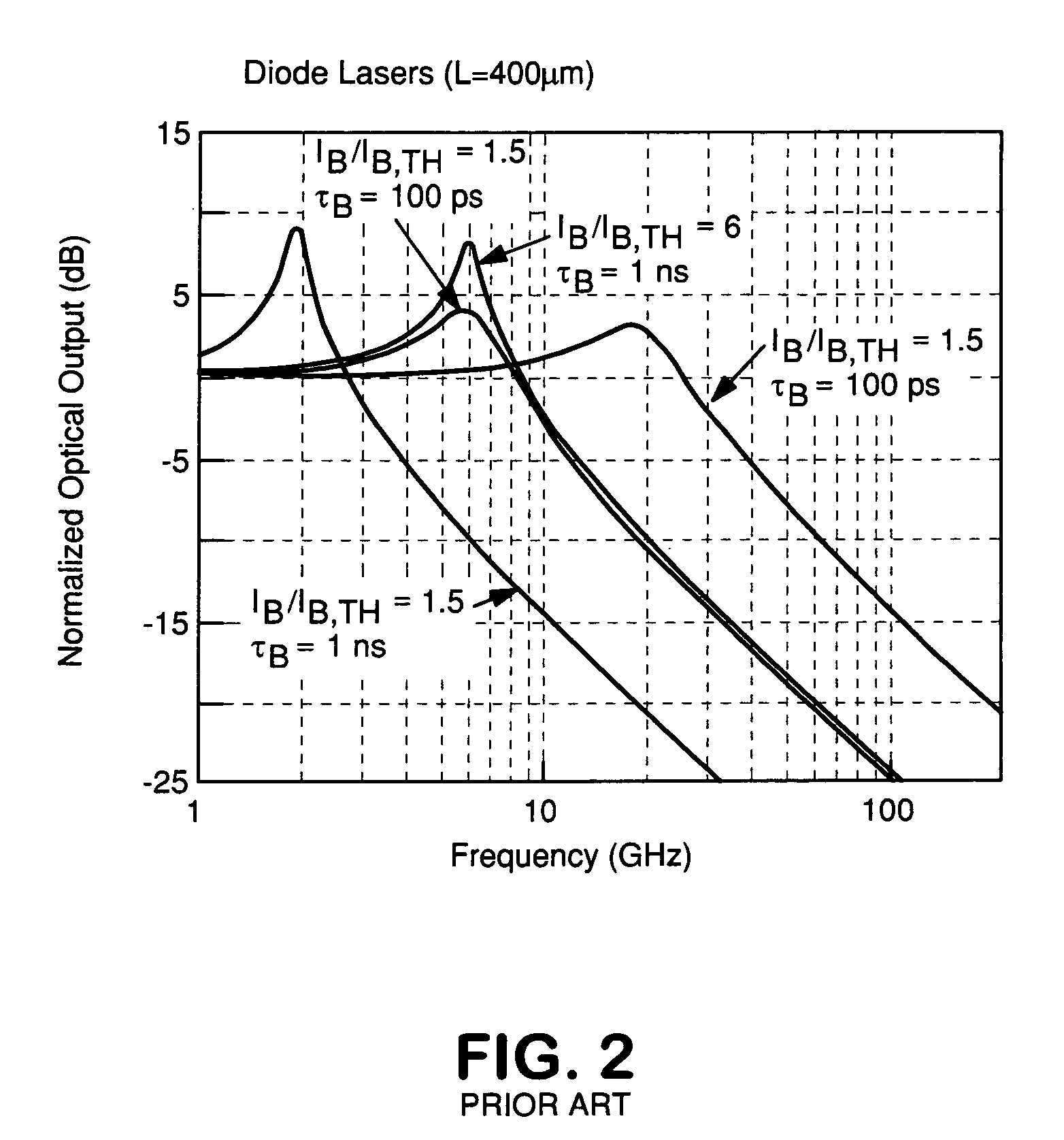

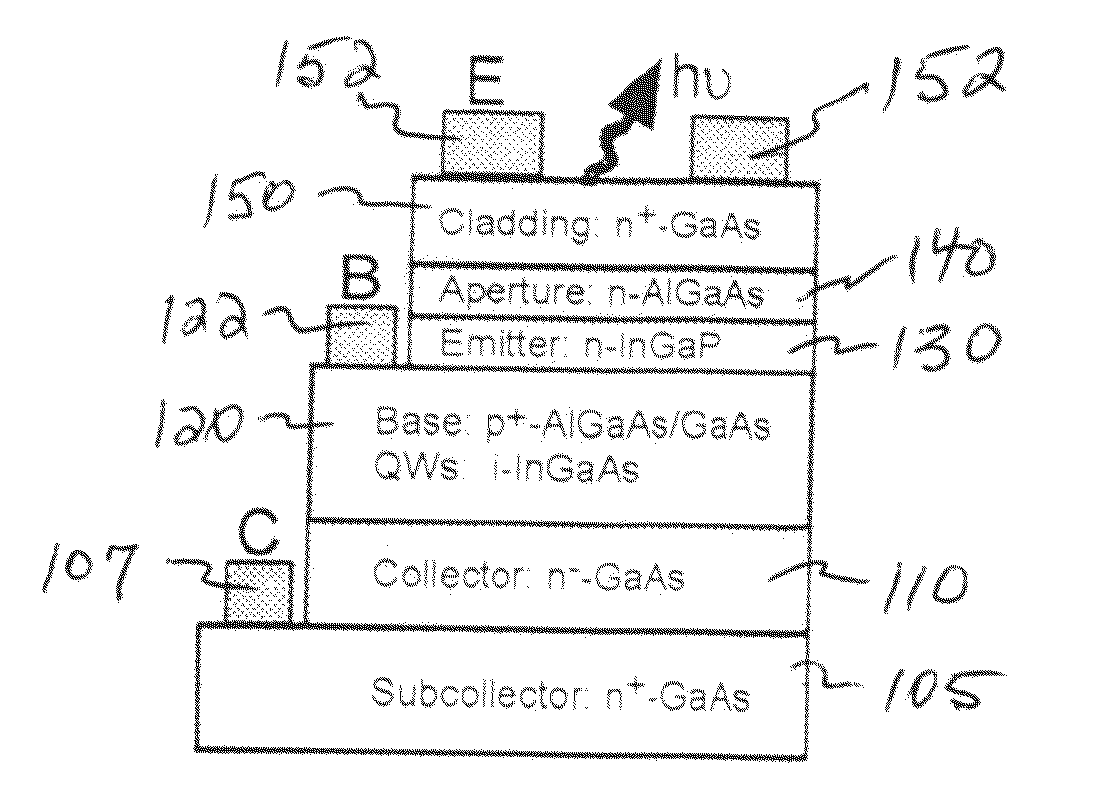

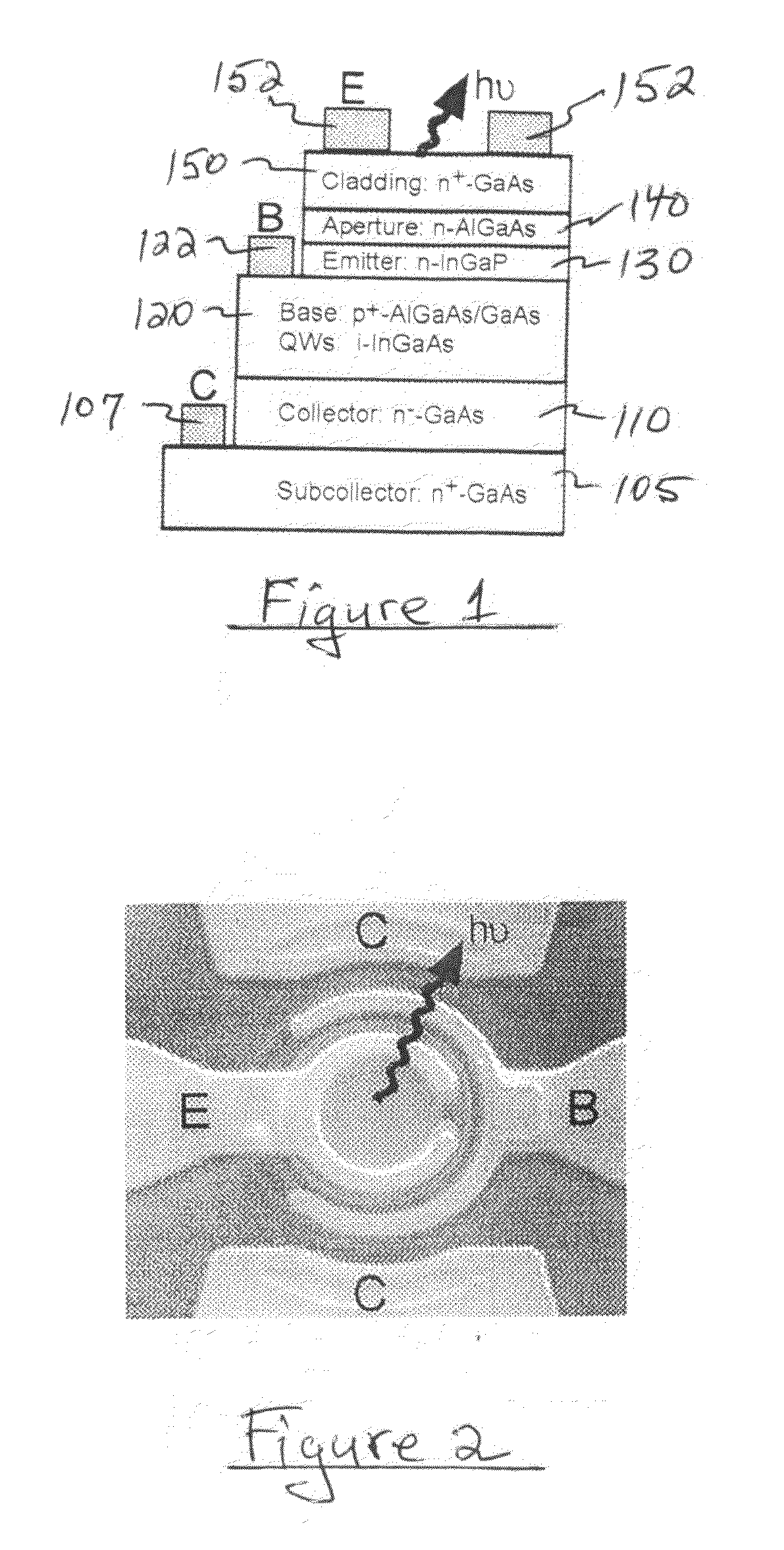

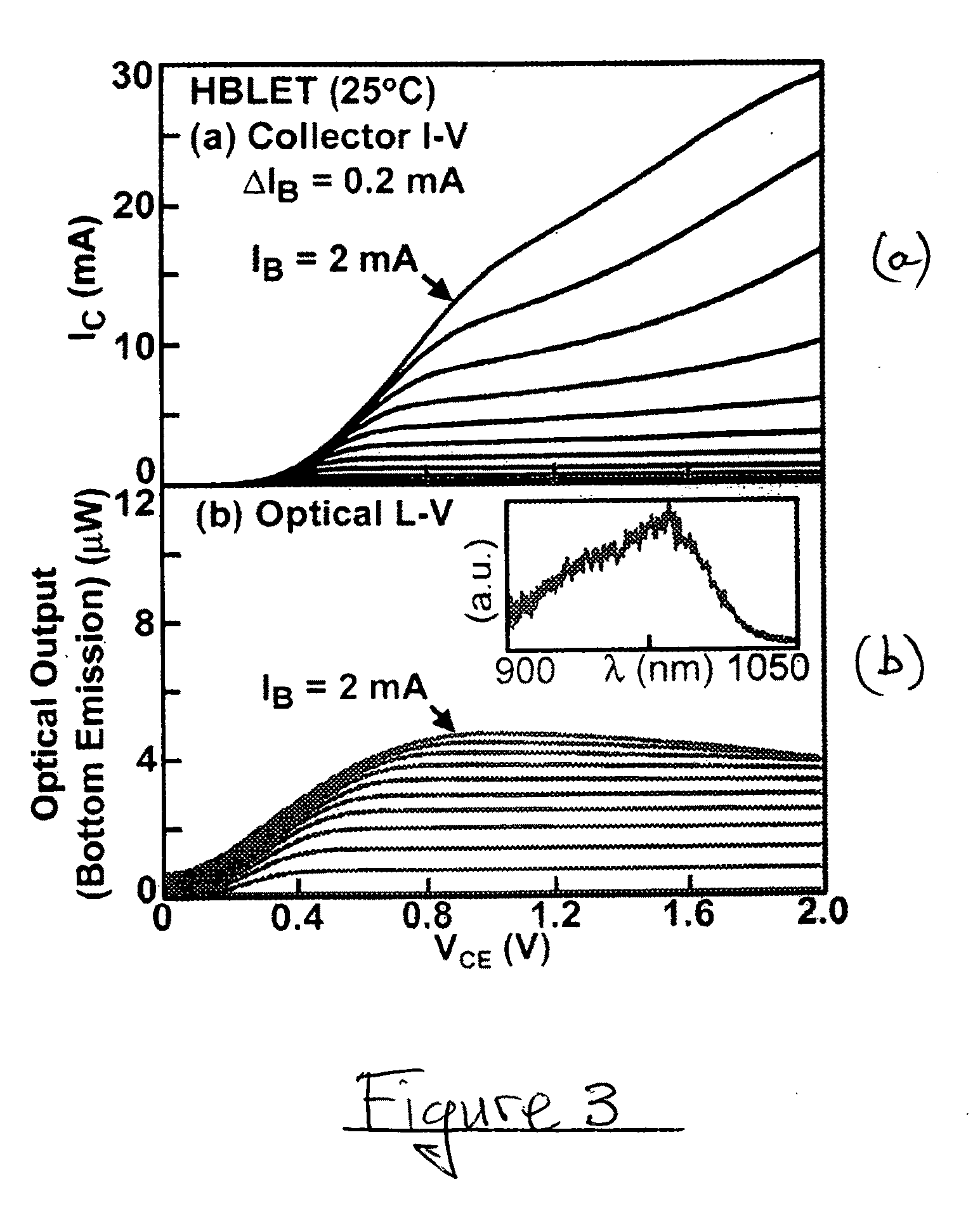

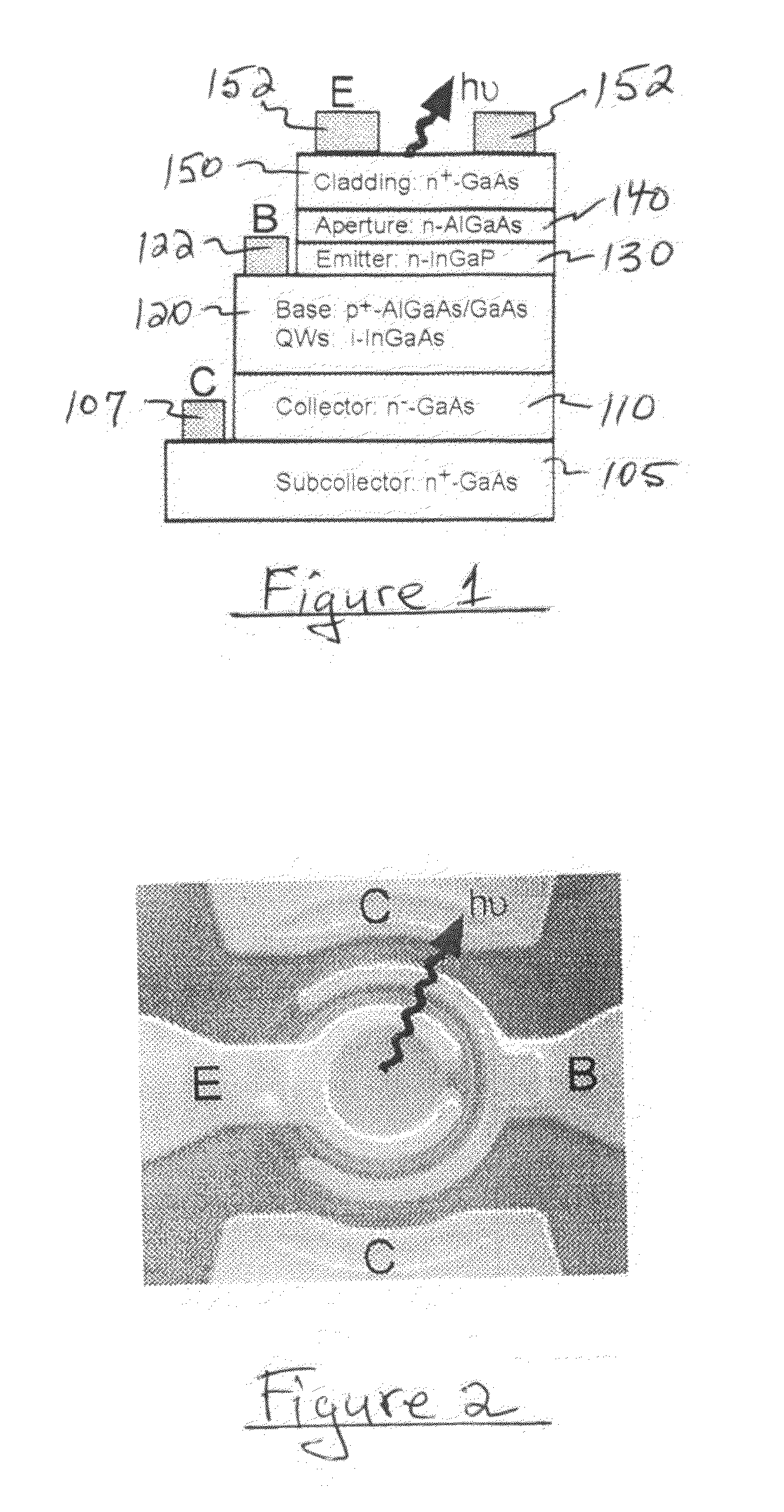

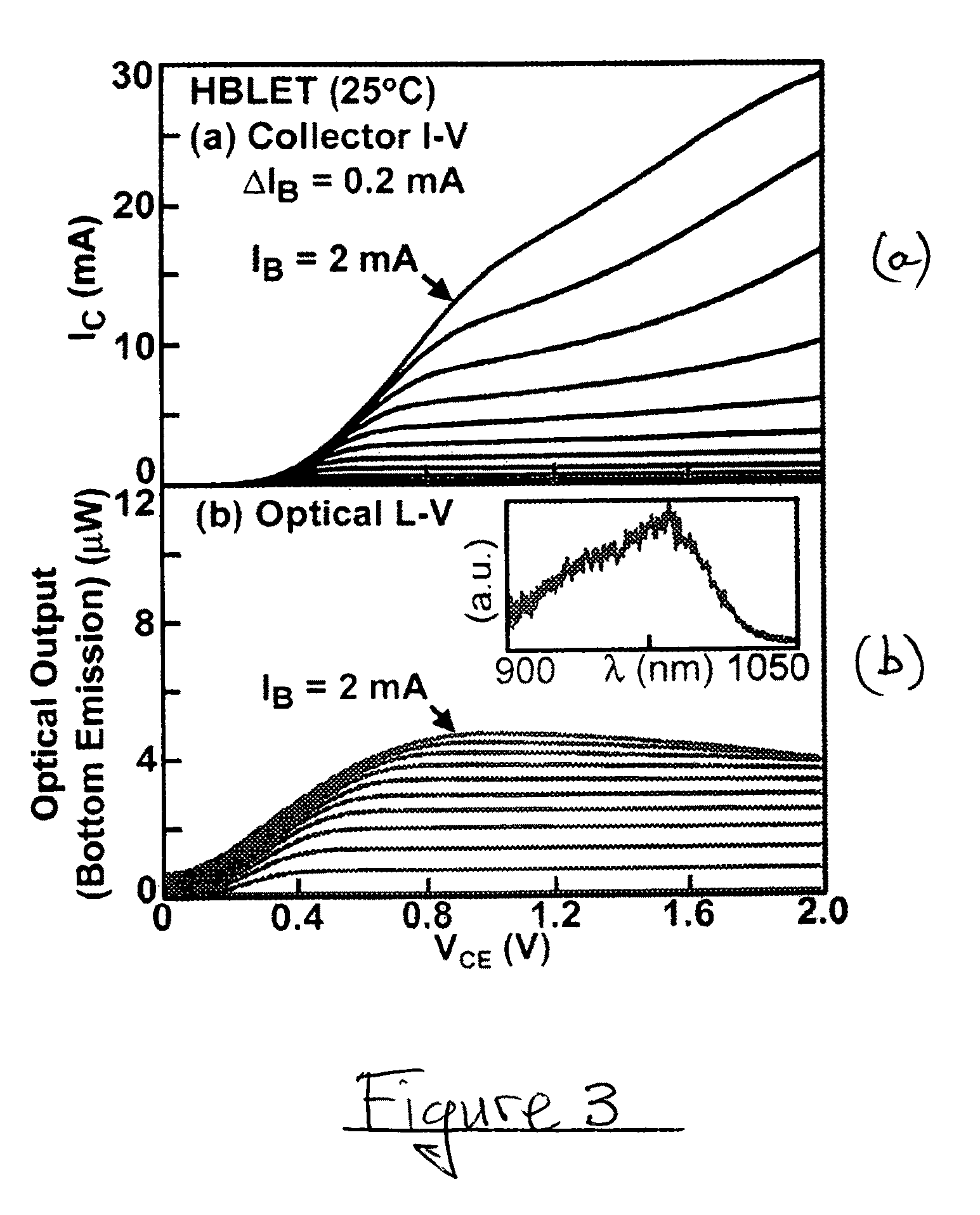

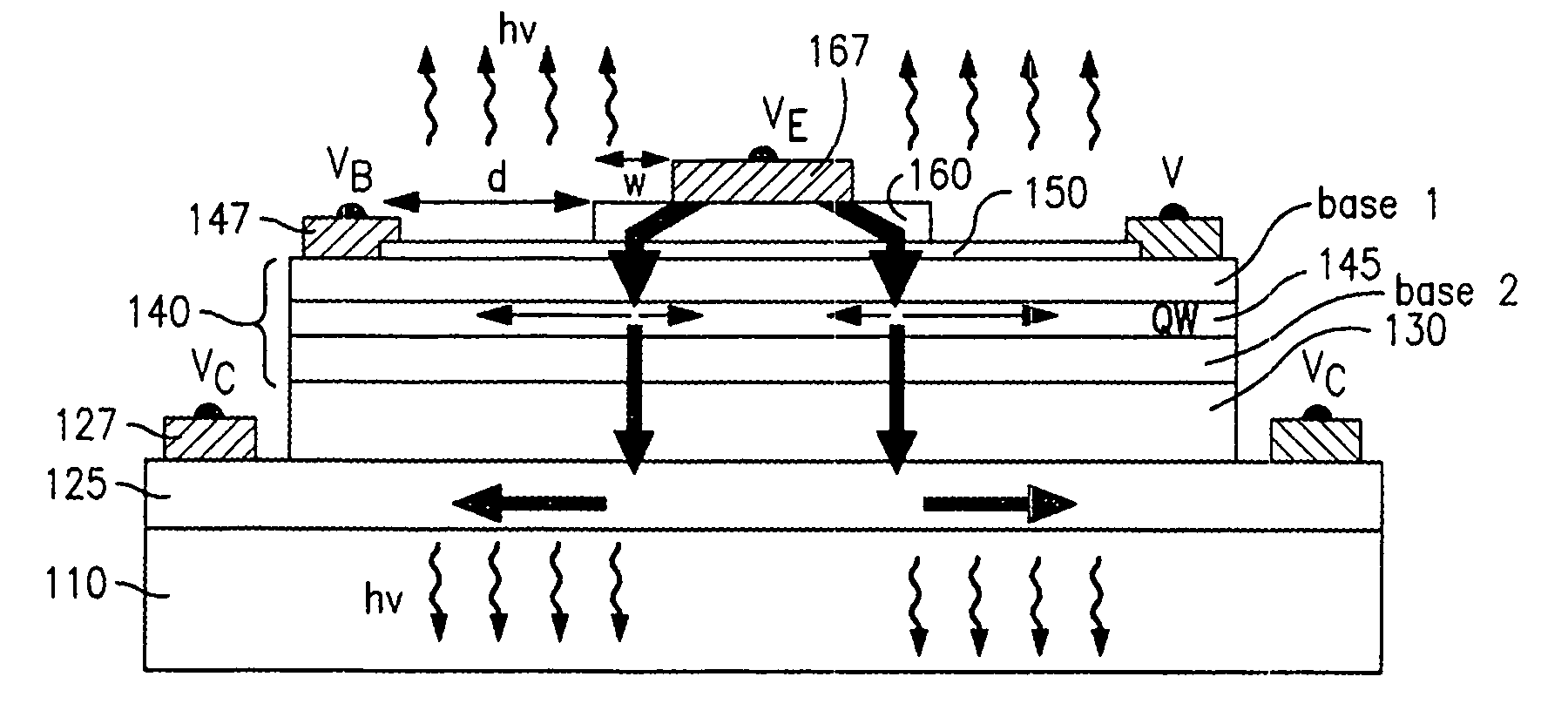

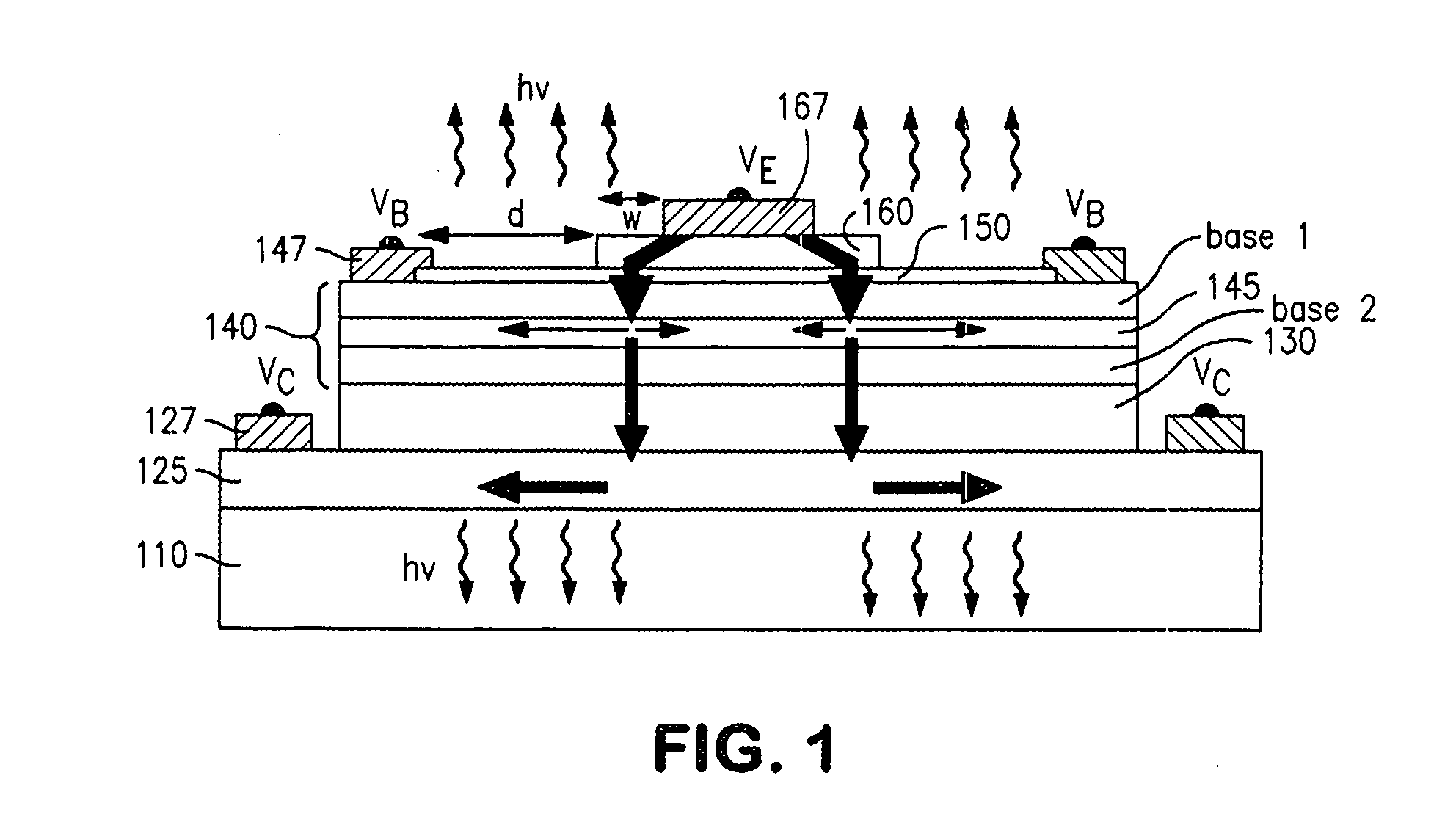

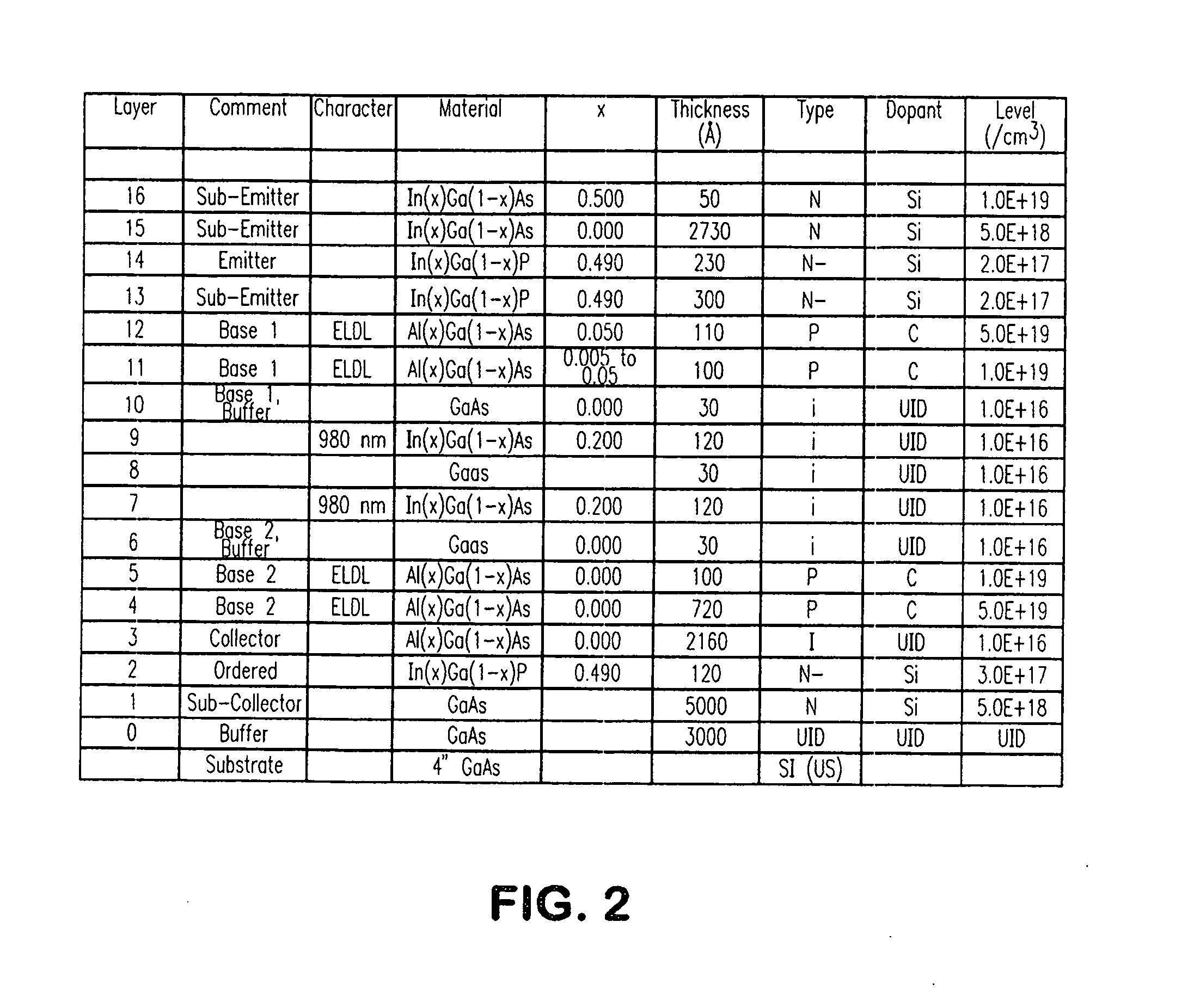

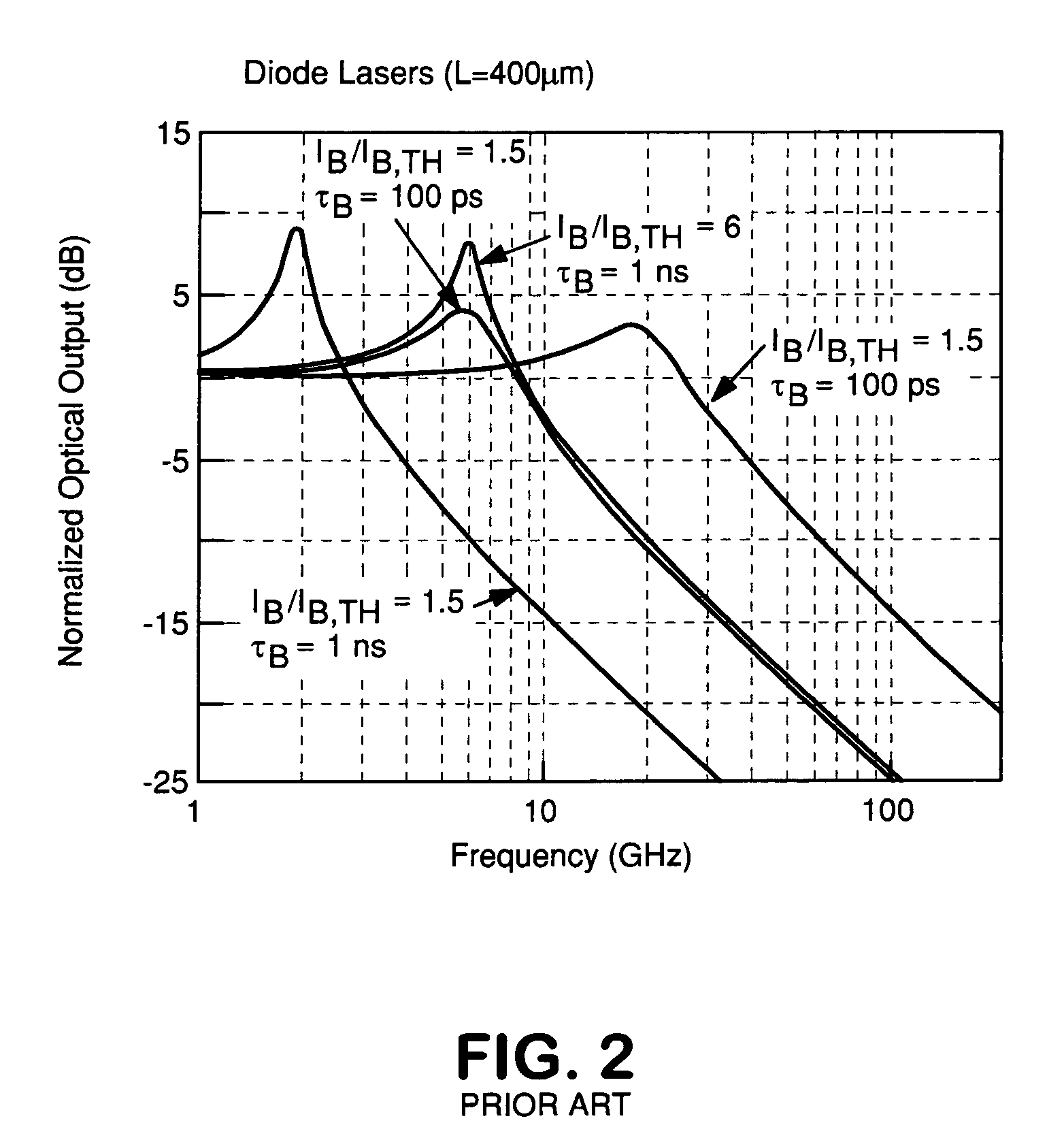

High speed light emitting semiconductor methods and devices

ActiveUS20100272140A1Improve featuresHigh yieldLaser detailsElectric lighting sourcesOptical cavityQuantum size effect

A method for producing a high frequency optical signal component representative of a high frequency electrical input signal component, includes the following steps: providing a semiconductor transistor structure that includes a base region of a first semiconductor type between semiconductor emitter and collector regions of a second semiconductor type; providing, in the base region, at least one region exhibiting quantum size effects; providing emitter, base, and collector electrodes respectively coupled with the emitter, base, and collector regions; applying electrical signals, including the high frequency electrical signal component, with respect to the emitter, base, and collector electrodes to produce output spontaneous light emission from the base region, aided by the quantum size region, the output spontaneous light emission including the high frequency optical signal component representative of the high frequency electrical signal component; providing an optical cavity for the light emission in the region between the base and emitter electrodes; and scaling the lateral dimensions of the optical cavity to control the speed of light emission response to the high frequency electrical signal component.

Owner:QUANTUM ELECTO OPTO SYST +1

Aqueous functional coatings possessing effects of self-cleaning, anti mold, sterilization and purifying air

A functional water paint with self-cleaning, antimildew, bactericiding and air-cleaning functions for building contains (5-100)-nm anatase-type titanium oxide as photocatalyst (10-46%) and water-soluble resin or polymer emulsion or silicon sol or their composition as water adhesive (26-35%). It features that the various organic substances in the air or water in contact with its surface can be decomposed into CO2 and water. Its advantages are high effect and safety and durable acting.

Owner:UNIV OF SCI & TECH OF CHINA

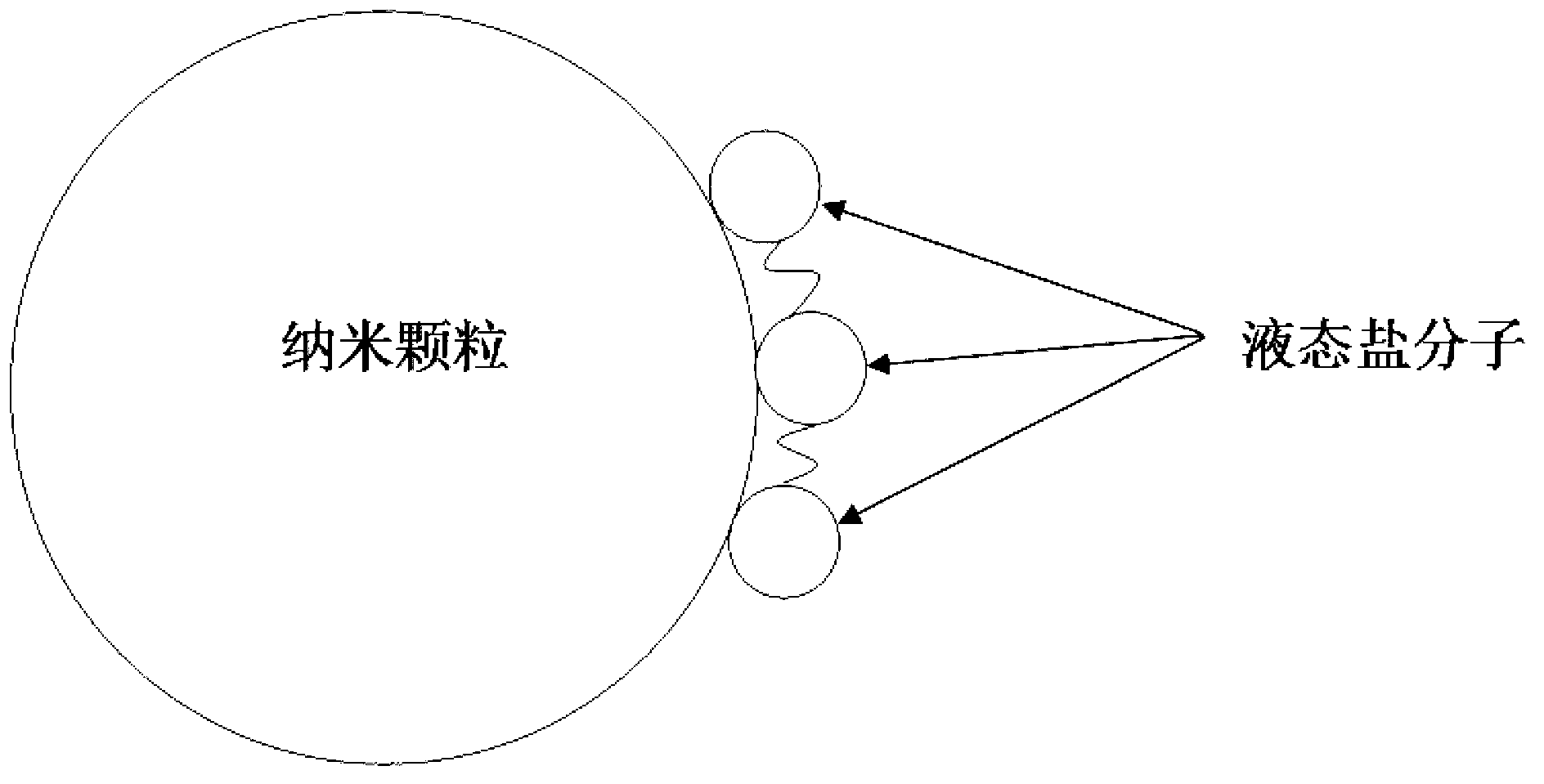

High-thermal-conductivity heat-storing nanometer-particle-mixed molten salt and preparation method thereof

InactiveCN103289653ASmall temperature fluctuationsImprove heat storage capacityHeat-exchange elementsHeat stabilitySolar power

The invention relates to the heat-storing field of solar thermal power generation, especially to a high-thermal-conductivity heat-storing nanometer-particle-mixed molten salt, and a preparation method thereof. The molten salt consists of a sold heat-storing molten salt, a dispersant and nanometer particles, wherein the dispersant and the nanometer particles disperse uniformly in the heat-storing molten salt and a eutectiform structure is formed, and the nanometer particles coat the surface of the heat-storing molten salt crystal particle. By adding the nanometer particles into the sold heat-storing molten salt, and by utilizing quantum size effect, surface effect, small size effect and the like possessed by the nanometer particles, the thermal physical property of the molten salt as a heat-storing medium has a substantial change. The preparation method is simple in technological process and low in cost, can help to substantially promote heat conductivity and specific heat capacity of the conventional heat-storing molten salt and substantially improve heat stability of the molten salt in a high temperature section, and can help to promote a heat storage capacity and system security of a concentrating solar power generation system and reduce costs of construction and operation of a power station.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

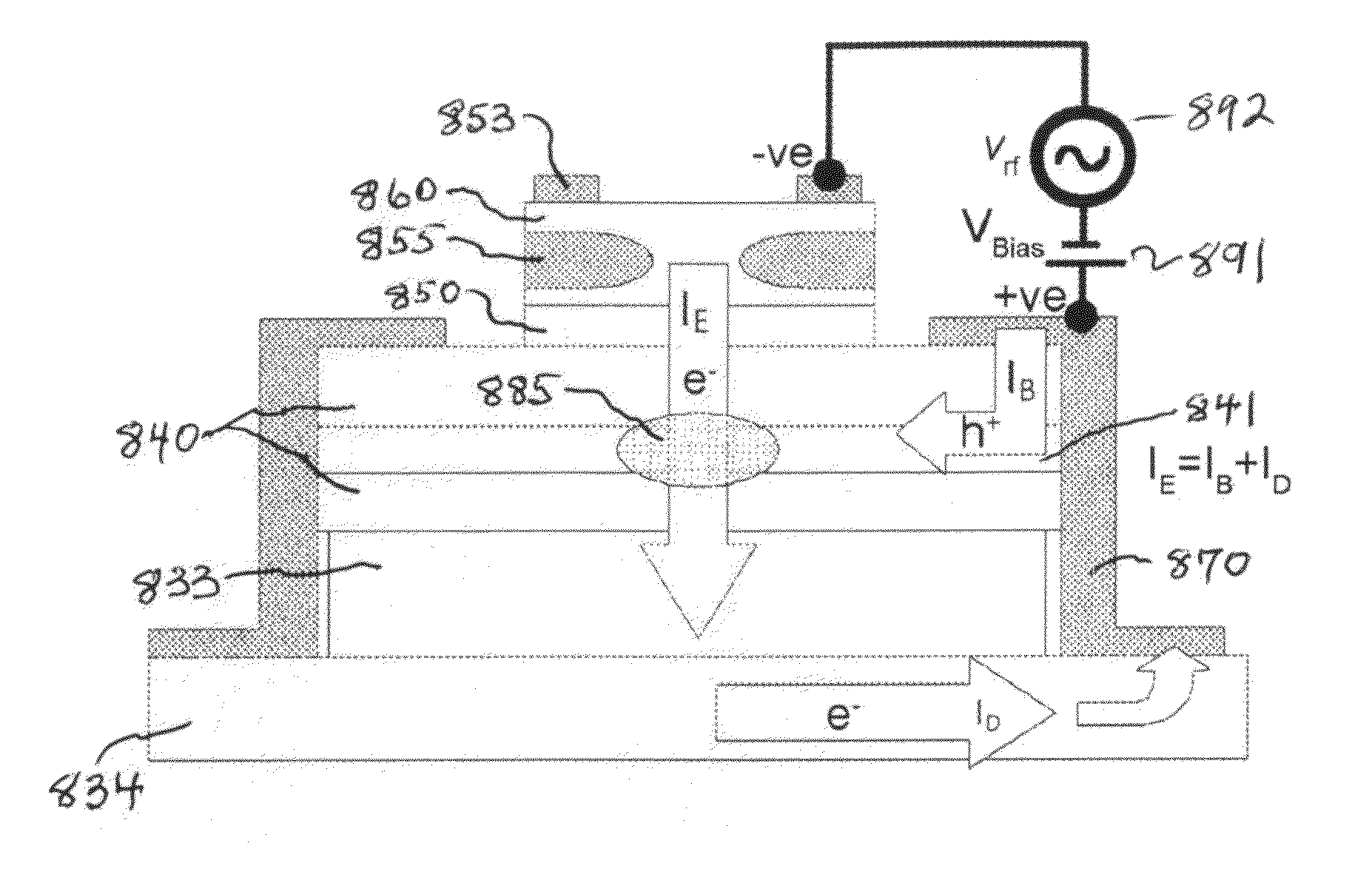

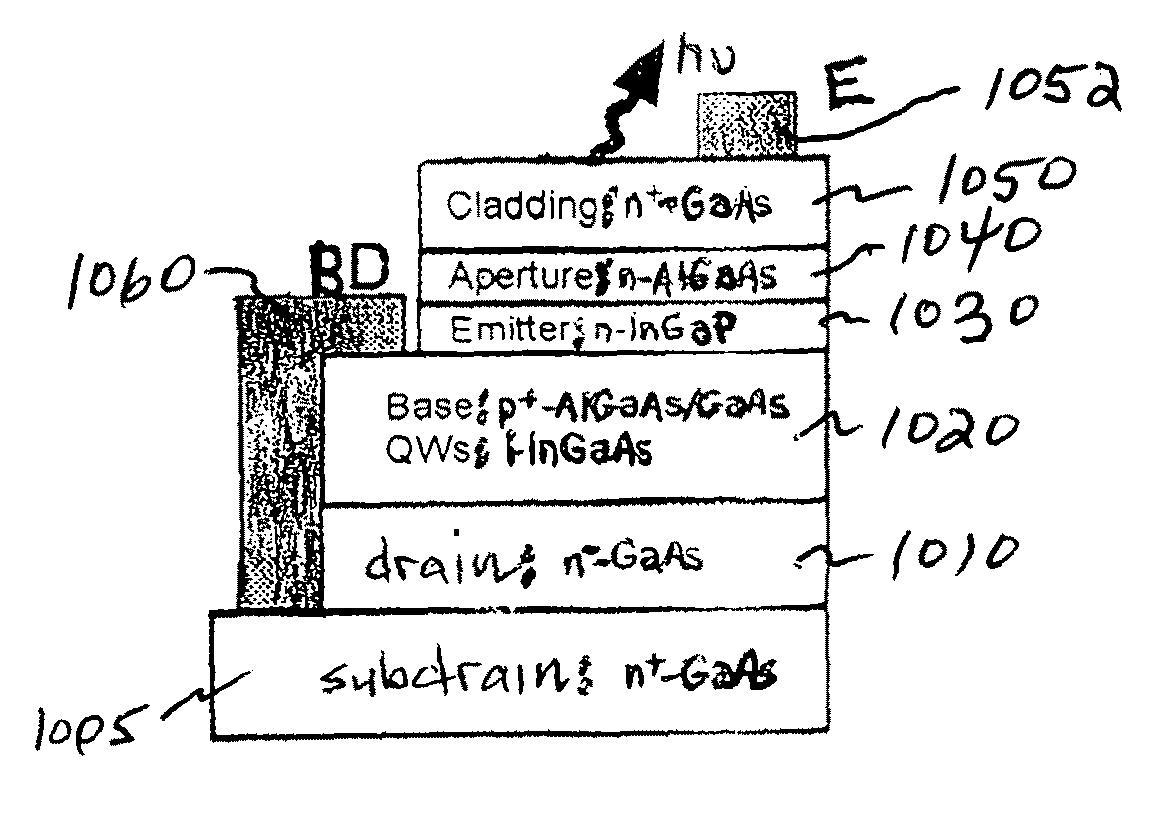

Two terminal light emitting and lasing devices and methods

InactiveUS20100202483A1Cheap manufacturingCheap to packageLaser detailsLaser active region structureElectrical conductorSemiconductor structure

A method for producing light emission from a semiconductor structure, including the following steps: providing a semiconductor structure that includes a first semiconductor junction between an emitter region of a first conductivity type and a base region of a second conductivity type opposite to that of the first conductivity type, and a second semiconductor junction between the base region and a drain region; providing, within the base region, a region exhibiting quantum size effects; providing an emitter electrode coupled with the emitter region; providing a base / drain electrode coupled with the base region and the drain region; and applying signals with respect to the emitter and base / drain electrodes to obtain light emission from the semiconductor structure.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

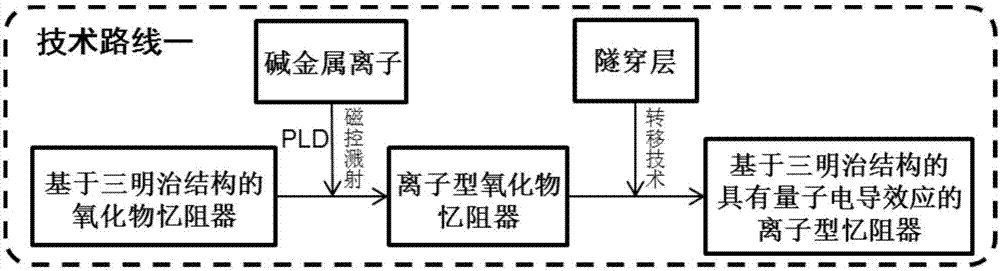

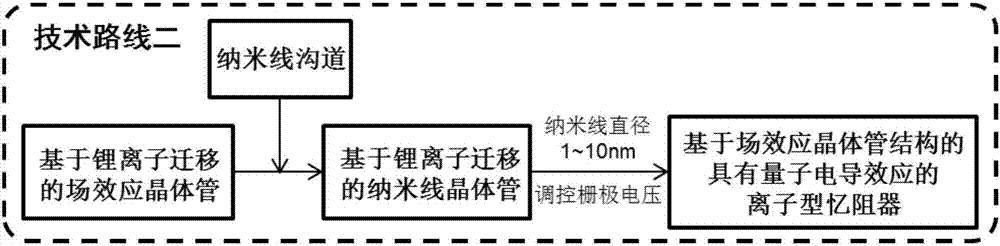

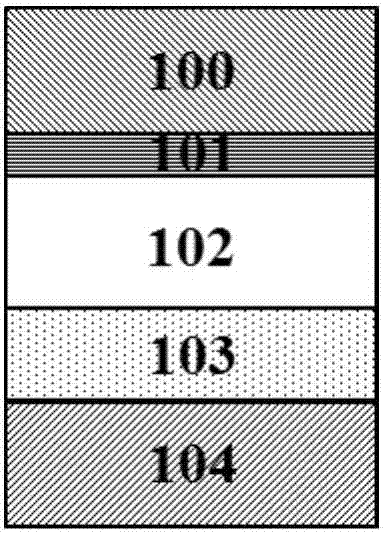

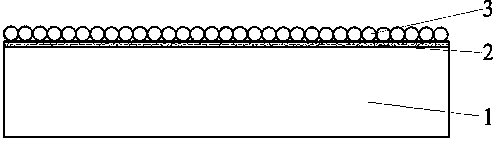

Ionic type memristor having quantum conductance effect

The invention discloses an ionic type memristor having a quantum conductance effect. The ionic type memristor has a "sandwich" structure or a field effect transistor structure. The ionic type memristor having the "sandwich" structure is composed of a top electrode, a tunneling layer, an oxide layer, an ion-doped layer and a bottom electrode. The specific structure is as follows: "the top electrode / the tunneling layer / the oxide layer / the ion-doped layer / the bottom electrode", "the top electrode / the oxide layer / the ion-doped layer / the tunneling layer / the bottom electrode" and "the top electrode / the oxide layer / the tunneling layer / the ion-doped layer / the bottom electrode". The top electrode has a thickness of 30-100 nm. The tunneling layer has a thickness of 0.34-5 nm. The oxide layer has a thickness of 10-40 nm. The ion-doped layer has a thickness of 10-40 nm. The bottom electrode has a thickness of 30-100 nm. The ionic type memristor of the invention can produce a memristive effect based on alkali metal or alkali metal ionic migration; and can achieve a quantum conductance effect using a tunneling effect when ions penetrate through the tunneling layer or a quantum size effect of a nanowire channel on the ions, so that multiple quantum states are observed.

Owner:BEIHANG UNIV

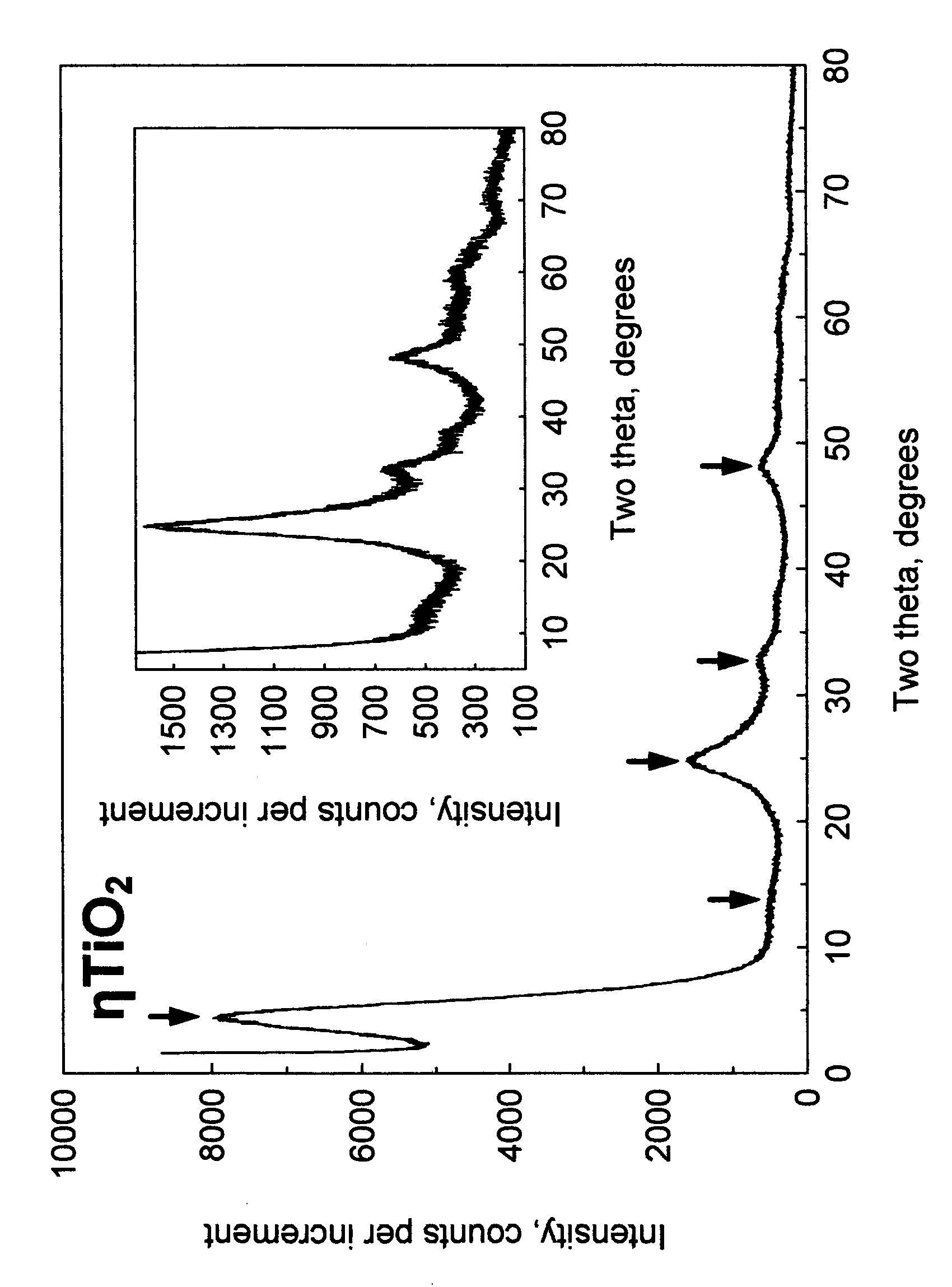

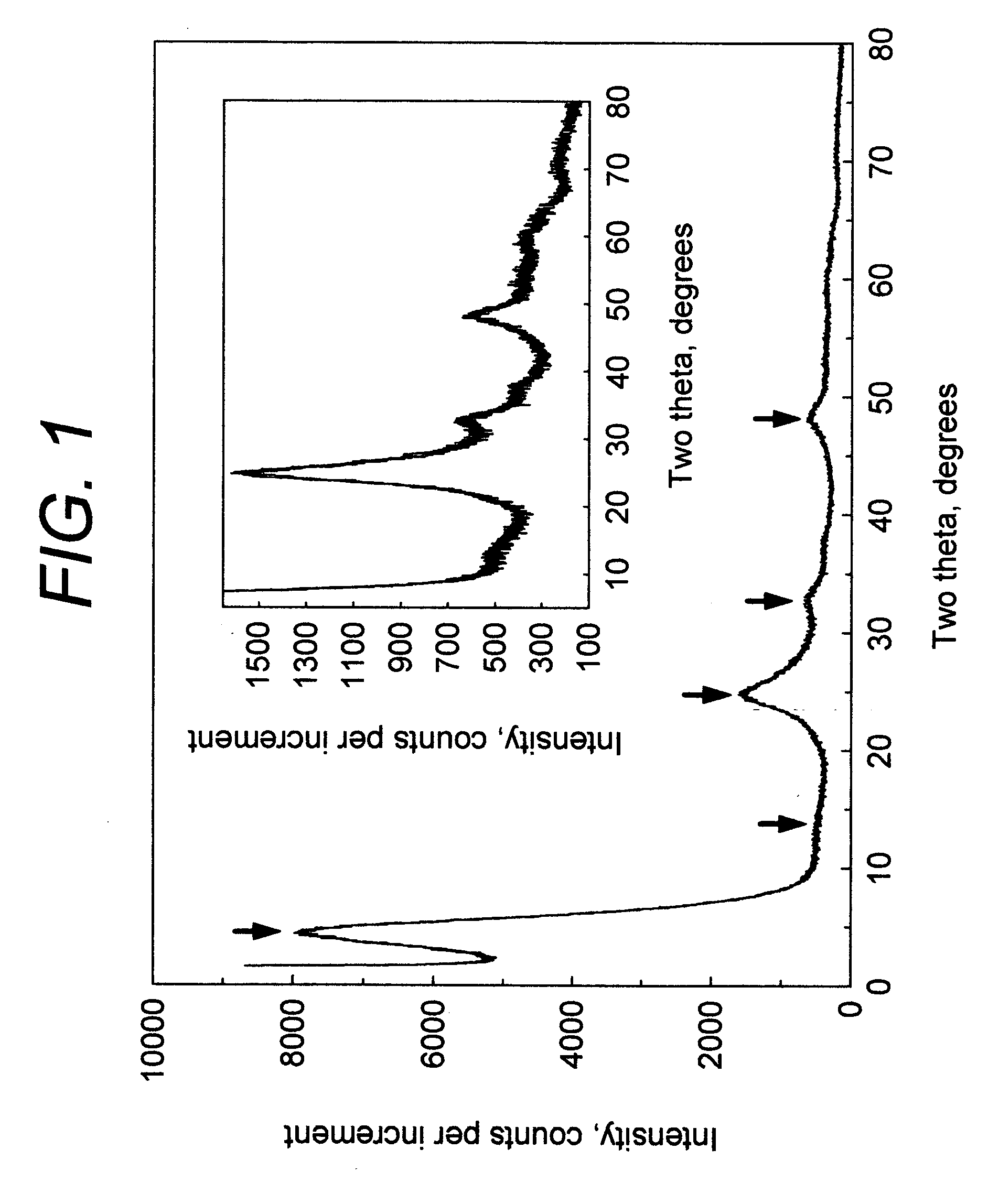

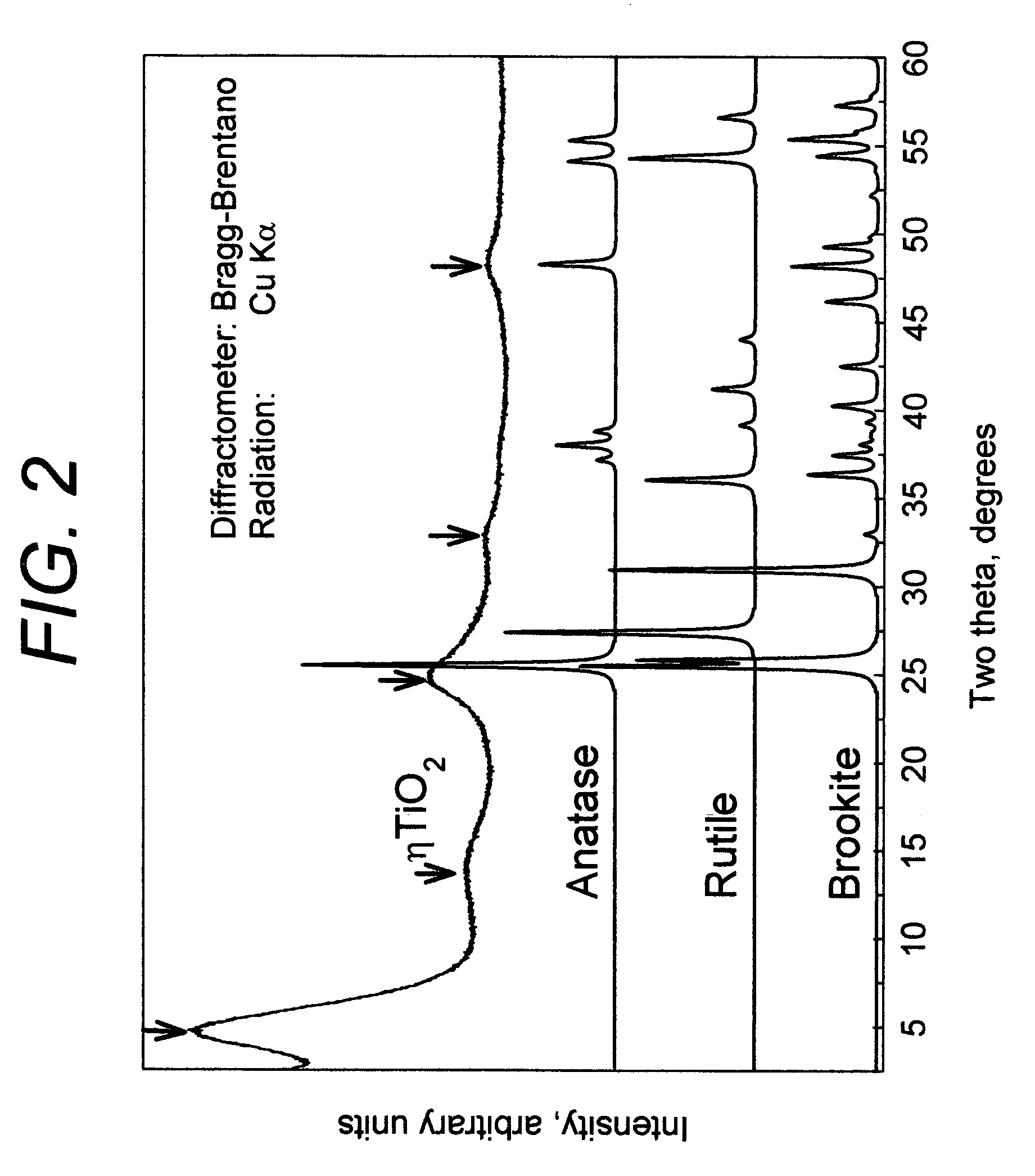

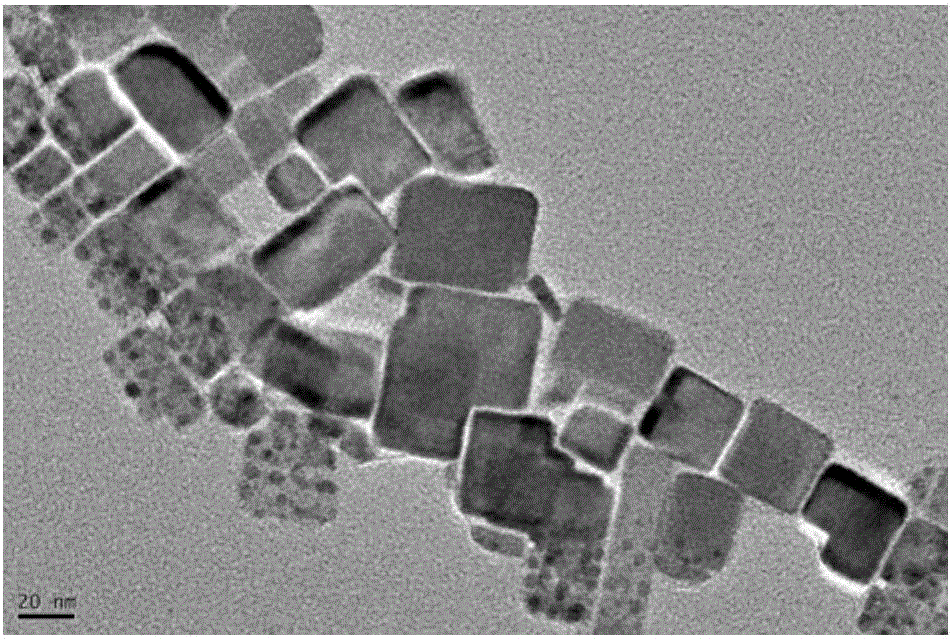

Novel titanium dioxide, process of making and method of using same

InactiveUS20060171877A1Inhibition formationQuantity minimizationPigmenting treatmentOther chemical processesSorbentRutile

Adsorbents and Methods used for effective removal or concentration or retention and recovery of harmful or valuable dissolved ions and compounds from aqueous systems using quantum size effect on large band gap semiconductors are provided. Invention provides methods for creating surface hydroxyl groups on surfaces of anatase, brookite and rutile which comprise methods of reducing dimensions of individual crystals to the sizes where surface hydroxyl groups are self generated via quantum size effects when they contacted with electrolytes. This invention also provides methods of preparation of quantum sized anatase, brookite and rutile. The invention also provides methods using quantum size effected anatase, brookite and rutile products for treatment of water, comprising rapid and high capacity adsorption of dissolved molecules and ions to the surface of said crystals via surface reaction process between said effect created hydroxyl groups with molecules and ions.

Owner:DADACHOV MAZAKHIR

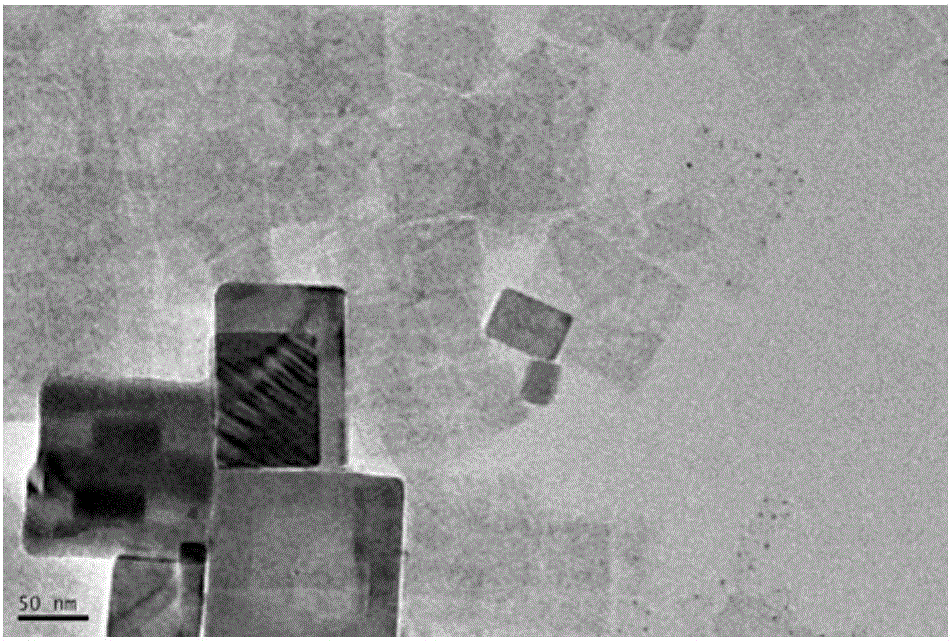

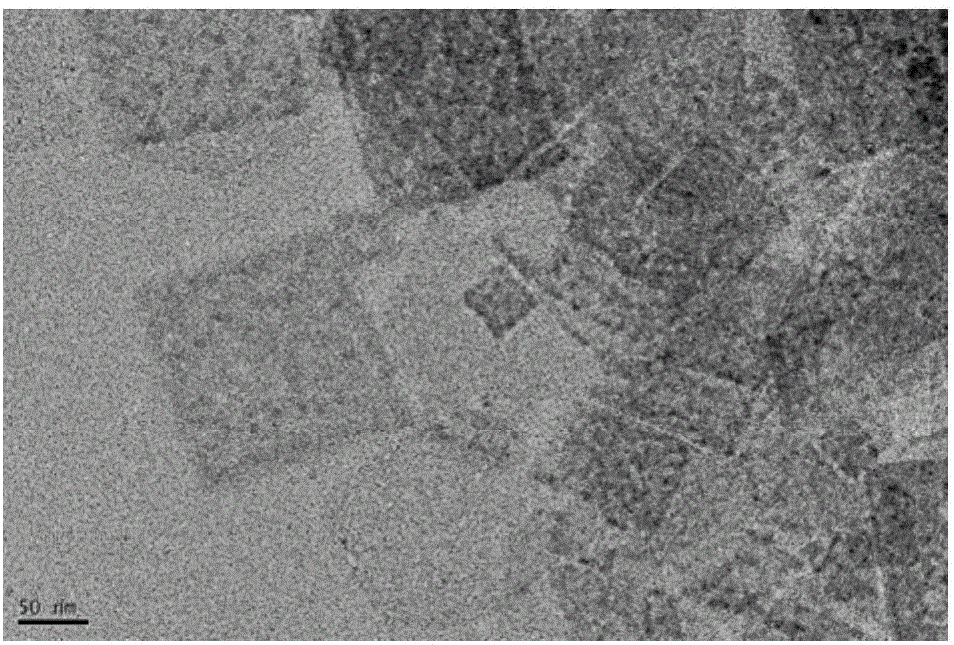

Method for preparing CsPbBr3 nanosheets with quantum size effects

InactiveCN106809872APreserve quantum size effectsAchieving controllable equipmentMaterial nanotechnologyLead compoundsOleic Acid TriglycerideQuantum size

The invention discloses a method for preparing CsPbBr3 nanosheets with quantum size effects. The method includes dissolving cesium carbonate in oleic acid under argon filling conditions, and stirring the cesium carbonate and the oleic acid under heating conditions until the cesium carbonate is dissolved to obtain cesium oleate precursors; adding lead bromide, long-chain ligands and short-chain ligands into octadecene under argon filling conditions, carrying out reaction at the temperature of 100-150 DEG C until the lead bromide is dissolved, heating first reaction products until the temperature of the first reaction products reaches 120-150 DEG C, then injecting the cesium oleate precursors into the first reaction products, carrying out reaction for 5-15 s, then continuing to carry out reaction at the temperature of 100-130 DEG C for 1-5 min to obtain second reaction products and centrifuging the second reaction products. The method has the advantages that the transverse sizes of the CsPbBr3 nanosheets can be assuredly regulated and controlled in the range from 100 nm to 1 micrometer while the thicknesses which are equal to the thicknesses of a few atomic layers can be guaranteed; the thicknesses which are lower than the diameters of Bohr excitons can be kept, and accordingly the quantum size effects of the CsPbBr3 nanosheets can be reserved.

Owner:XI AN JIAOTONG UNIV

High speed light emitting semiconductor methods and devices

ActiveUS8179937B2Improve featuresRecombine rapidlyLaser detailsElectric lighting sourcesElectricityOptical cavity

A method for producing a high frequency optical signal component representative of a high frequency electrical input signal component, includes the following steps: providing a semiconductor transistor structure that includes a base region of a first semiconductor type between semiconductor emitter and collector regions of a second semiconductor type; providing, in the base region, at least one region exhibiting quantum size effects; providing emitter, base, and collector electrodes respectively coupled with the emitter, base, and collector regions; applying electrical signals, including the high frequency electrical signal component, with respect to the emitter, base, and collector electrodes to produce output spontaneous light emission from the base region, aided by the quantum size region, the output spontaneous light emission including the high frequency optical signal component representative of the high frequency electrical signal component; providing an optical cavity for the light emission in the region between the base and emitter electrodes; and scaling the lateral dimensions of the optical cavity to control the speed of light emission response to the high frequency electrical signal component.

Owner:QUANTUM ELECTO OPTO SYST +1

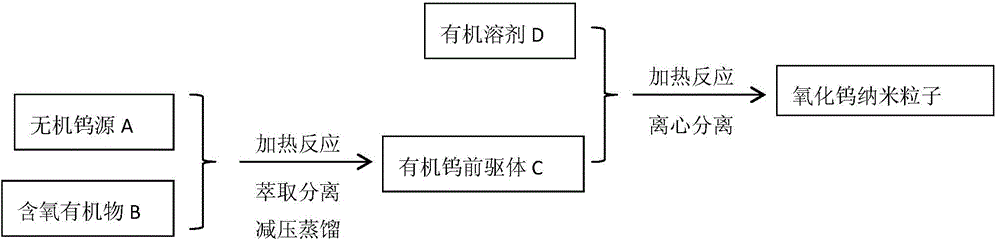

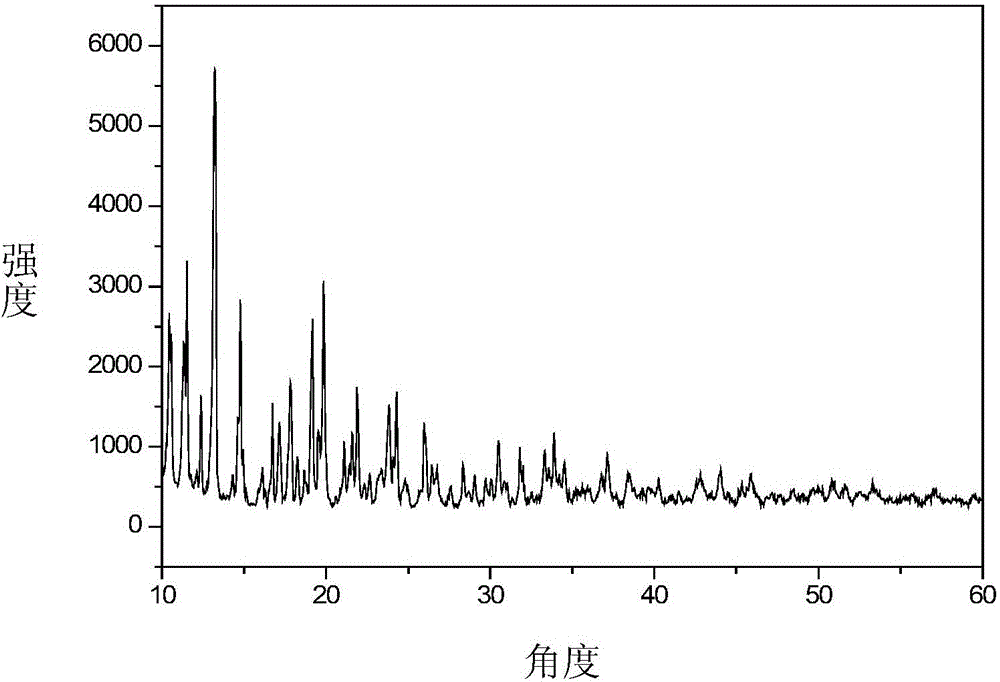

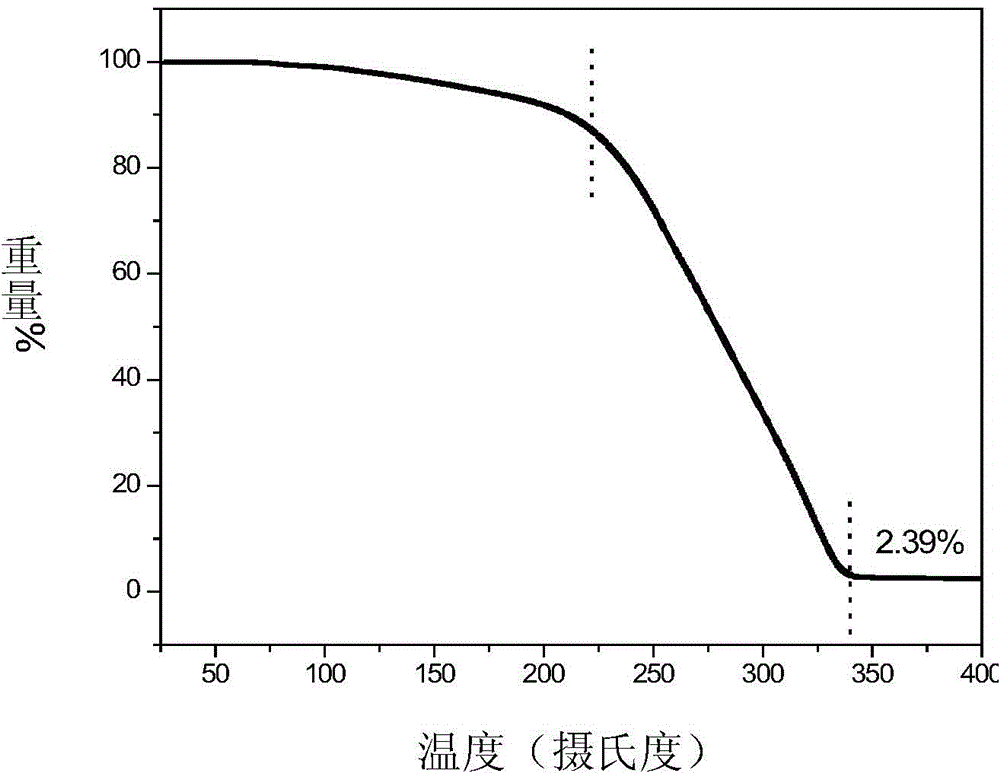

Tungsten oxide quantum dot material and preparation method thereof

ActiveCN104789218ALow costUniform particle sizeTungsten oxides/hydroxidesNanotechnologyOrganic solventNanoparticle

The invention provides a tungsten oxide quantum dot material and a preparation method thereof. The tungsten oxide quantum dot material comprises tungsten oxide nanoparticles with the particle size of several nanometers to a dozen of nanometers, the particle size of the tungsten oxide nanoparticles is uniform, the surface of the nanoparticles is covered with an organic matter coating layer, and the nanoparticles can be highly dispersed in a non-polar organic solvent, and has a quantum dimension effect. Preferably, the particle size of the tungsten oxide quantum dot material is smaller than 2nm; and the tungsten oxide quantum dot material can be prepared through a liquid phase method, and is prepared through two steps of preparing an organic tungsten precursor from an easily available inorganic tungsten compound and preparing the material. The preparation method has the advantages of simple process flow, easily available raw material, good reappearance and high controllability, and the obtained tungsten oxide nanoparticles have the advantages of uniform particle size, adjustable dimension, high dispersion, obvious quantum dimension effect and wide application prospect.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for manufacturing field-effect transistor based on quantum dot film conducting channel

ActiveCN104051275ATaking advantage of quantum size effectsFlexible and controllable performanceTransistorSemiconductor/solid-state device manufacturingEvaporationQuantum size effect

The invention discloses a method for manufacturing a field-effect transistor based on a quantum dot film conducting channel. The advanced quantum dot assembly technology is utilized, a single CdSe quantum dot array film is assembled out on a silicon / silicon dioxide substrate to serve as the conducting channel of the field-effect transistor, Cr / Au composite metal electrodes are formed on the single CdSe quantum dot array film and the substrate silicon of the film through a graphical mask covering evaporation process technology respectively, a source electrode, a drain electrode and a grid electrode are correspondingly led out, the quantum dot channel is effectively packaged and protected by spin-coating of organic matter, and consequently the novel field-effect transistor based on the quantum dot film conducting channel is manufactured out. The manufacturing method is novel, low in manufacturing cost, simple in manufacturing process, accurate and controllable, the manufactured field-effect transistor is provided with the special quantum dot array film conducting channel, the quantum size effect of the quantum dot array film can be fully utilized, and therefore the sensitivity of the transistor is effectively improved, and the method has very significant application value in novel photoelectric devices.

Owner:FUZHOU UNIV

Hydrotalcite quantum dot electrocatalyst, preparation method thereof, application of hydrotalcite quantum dot electrocatalyst in electrocatalytic decomposition of water to produce oxygen

ActiveCN104607191ALow costSimple and fast operationElectrolysis componentsMetal/metal-oxides/metal-hydroxide catalystsDecompositionQuantum dot

The invention discloses a hydrotalcite quantum dot electrocatalyst. The hydrotalcite quantum dot electrocatalyst adopts a chemical formula (I): [M<2+>1-xN<3+>x(OH)2]<x+>.(A<n->)x / n.mH2O (I), or a chemical formula (II): [M<2+>1-xY<4+>x(OH)2]<2x+>.(A<n->)2x / n.mH2O (II), wherein M<2+> is one or more of Ni<2+>, Zn<2+>, Mg<2+> and Ca<2+>; N<3+> is one or more of Co<3+>, Fe<3+>, Cr<3+>, Al<3+> and Mn<3+>; Y<4+> is Ti<4+>; A<n-> is NO3<-> or CO3<2->; x is larger than or equal to 0.16 and smaller than or equal to 0.50; n is the valence number of a negative ion; m is the quantity of crystal water, and is larger than or equal to 0.5 and smaller than or equal to 9; the hydrotalcite quantum dot electrocatalyst is 5 to 100 nm in size, and 0.5 to 5 nm in thickness. The invention further provides a preparation method and application of the hydrotalcite quantum dot electrocatalyst. The hydrotalcite quantum dot electrocatalyst has an obvious quantum size effect, and an excellent catalytic performance in electrocatalytic decomposition of water to produce oxygen, and is greatly lower in overpotential. The preparation method is low in cost, and simple and convenient to operate. The hydrotalcite quantum dot electrocatalyst can be applied to the fields such as photoelectrocatalysis.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Catalyst for removing organic sulfur in clean coal gas through hydrolysis and preparation method thereof

ActiveCN102179241ANo collapseHigh strengthGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalRare earth

The invention discloses a catalyst for removing organic sulfur in clean coal gas through hydrolysis, which comprises an attapulgite, a carrier and an active component; the catalyst is characterized in that the carrier is titanium dioxide carrier; and the active component is one or more of barium sulfate, rare earth, alkaline earth and synthesized perovskite composite metal oxide. The catalyst uses modified titanium dioxide as main body and is provided with the attapulgite; the catalyst has sulfation resistance, good hydrothermal resisting stability, and relatively larger specific surface and pore volume; the rare earth is used for adjusting the surface acidity of the catalyst; the synthesized perovskite composite metal oxide is used as the active component; and the catalyst has the characteristics which are not contained in common material in the aspects of particles such as small size effect, surface effect, quantum size effect and macroscopic quantum tunneling effect. The invention further discloses a preparation method of the catalyst for removing organic sulfur in clean coal gas through hydrolysis.

Owner:SANLONG CATALYST

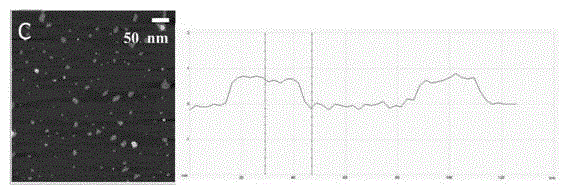

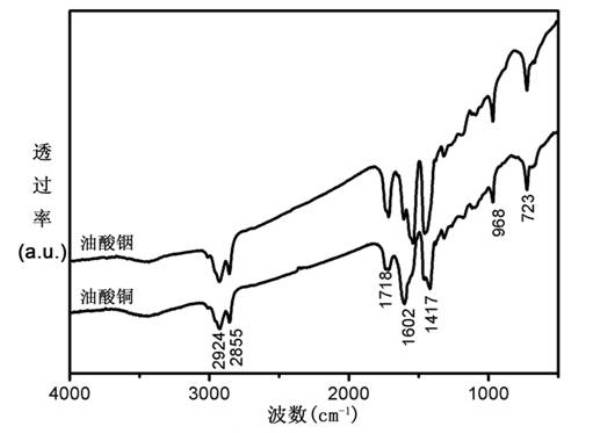

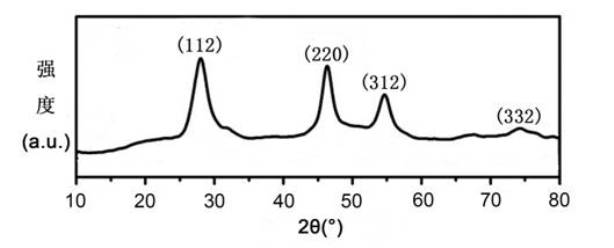

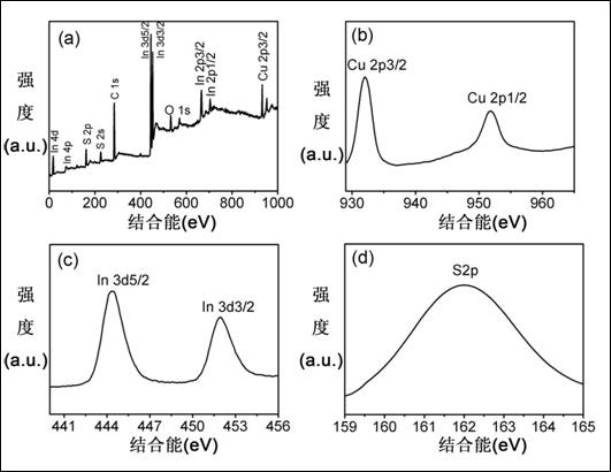

Preparation method of CuInS2 nanocrystalline material

InactiveCN102041555ANo pollution in the processHigh purityPolycrystalline material growthFrom normal temperature solutionsPyriteQuantum size effect

The invention relates to a preparation method of CuInS2 nanocrystalline material which has a copper pyrite structure and a controllable size and is prepared by taking curpic oleate, indium oleate precursor and elemental sulphur as the raw material by a one-step chemical method. The invention has the advantages that the preparation method of the CuInS2 nanocrystalline material has simple operation, easy repetition, high purity of obtained CuInS2 nanocrystalline material,moderate reaction condition and no pollution, greatly lowers cost and is suitable for large-scale industrial production. The CuInS2 nanocrystalline material provided by the invention has quantum size effect, can serve as the adsorption material of solar cells and has an important meaning to the practical application of the material in the solar cell fiel.

Owner:NANKAI UNIV

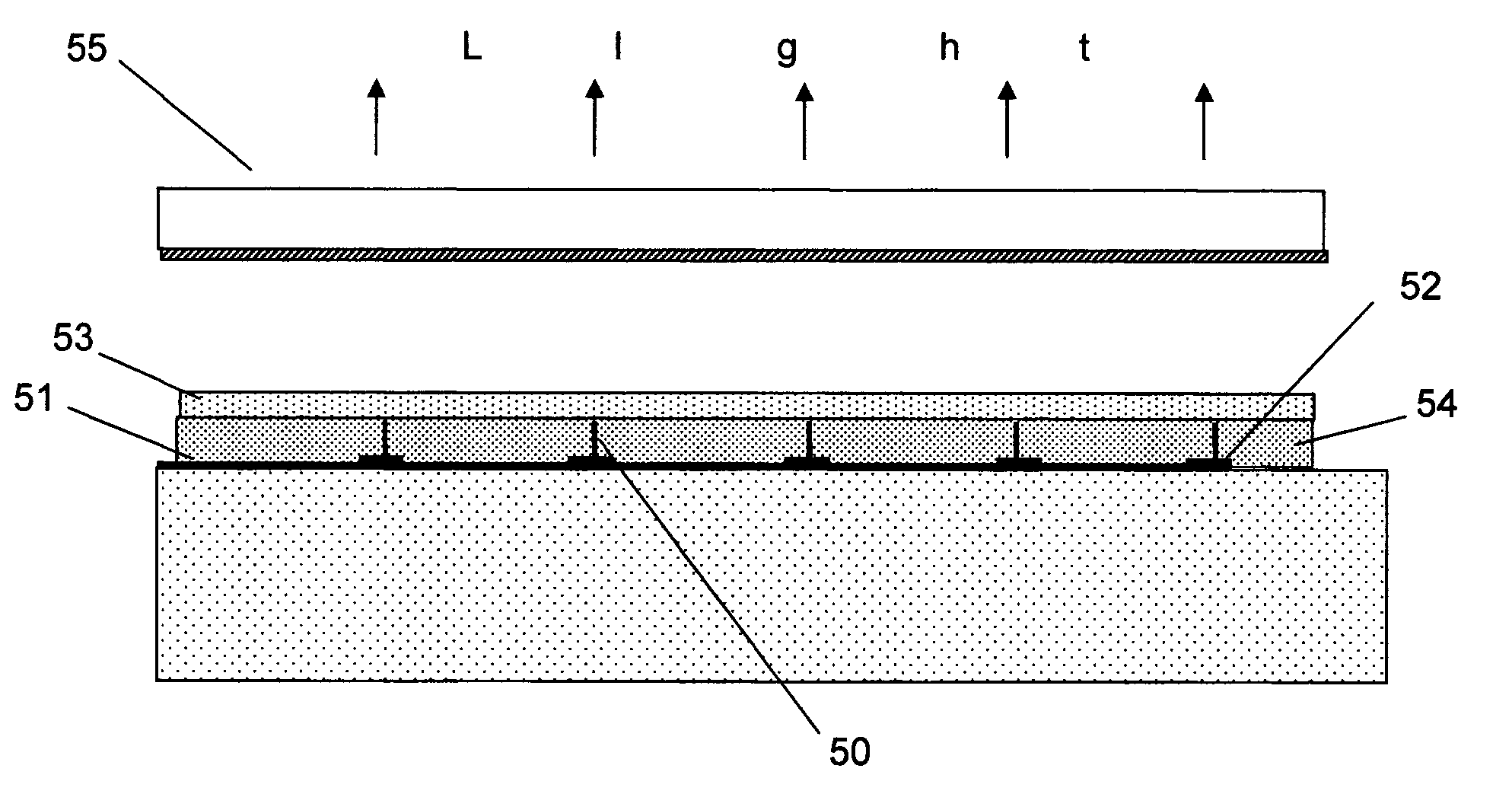

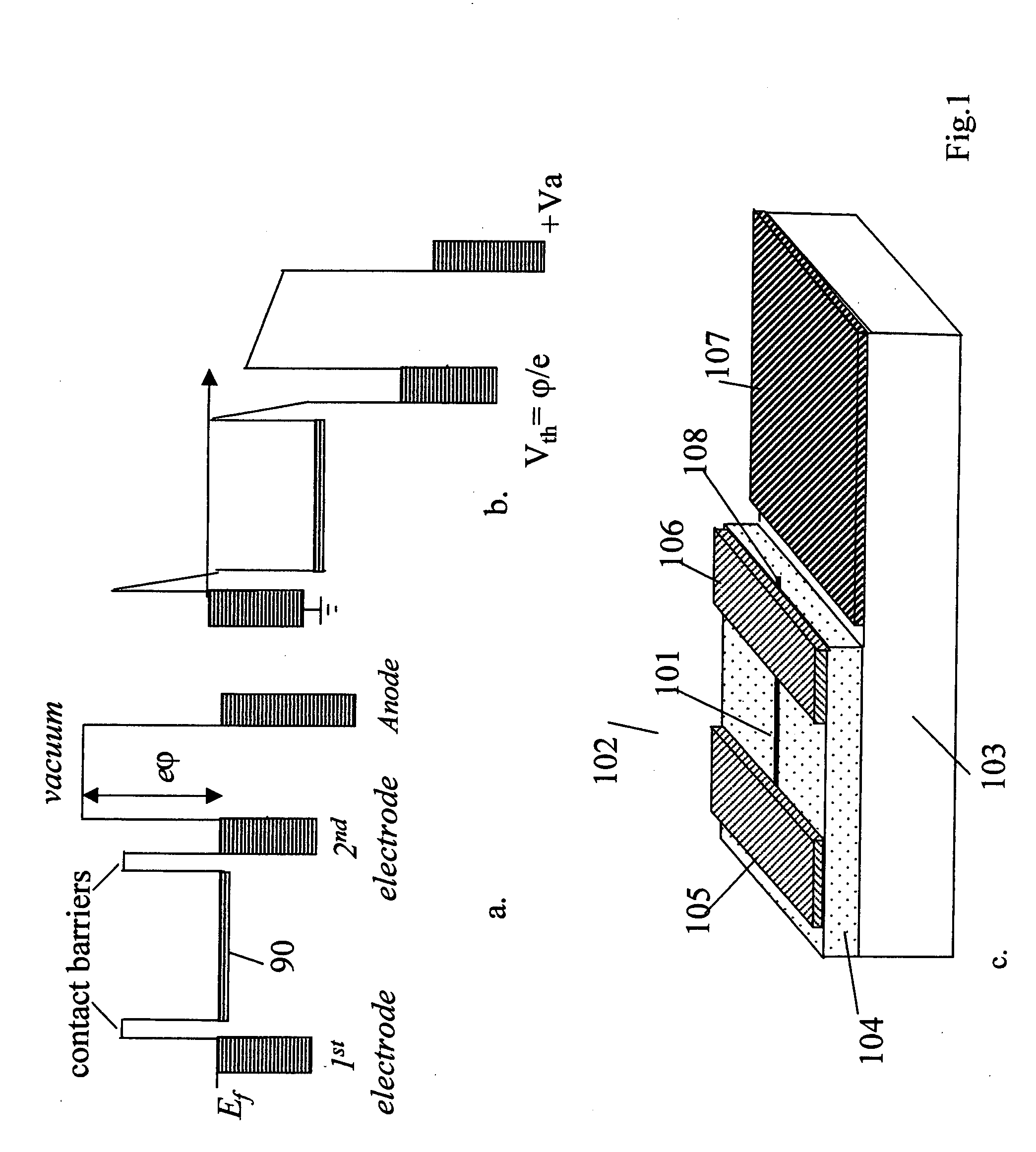

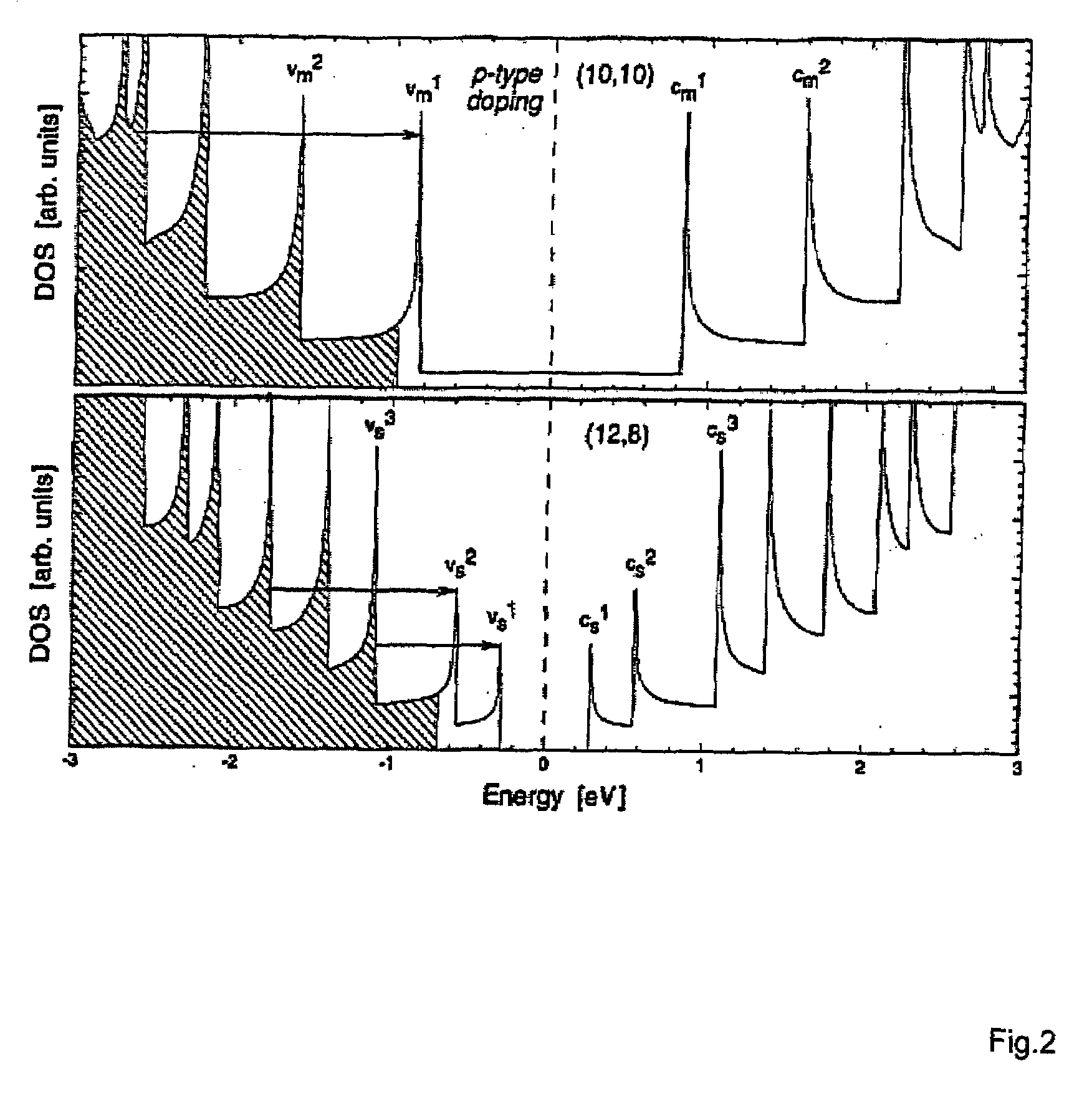

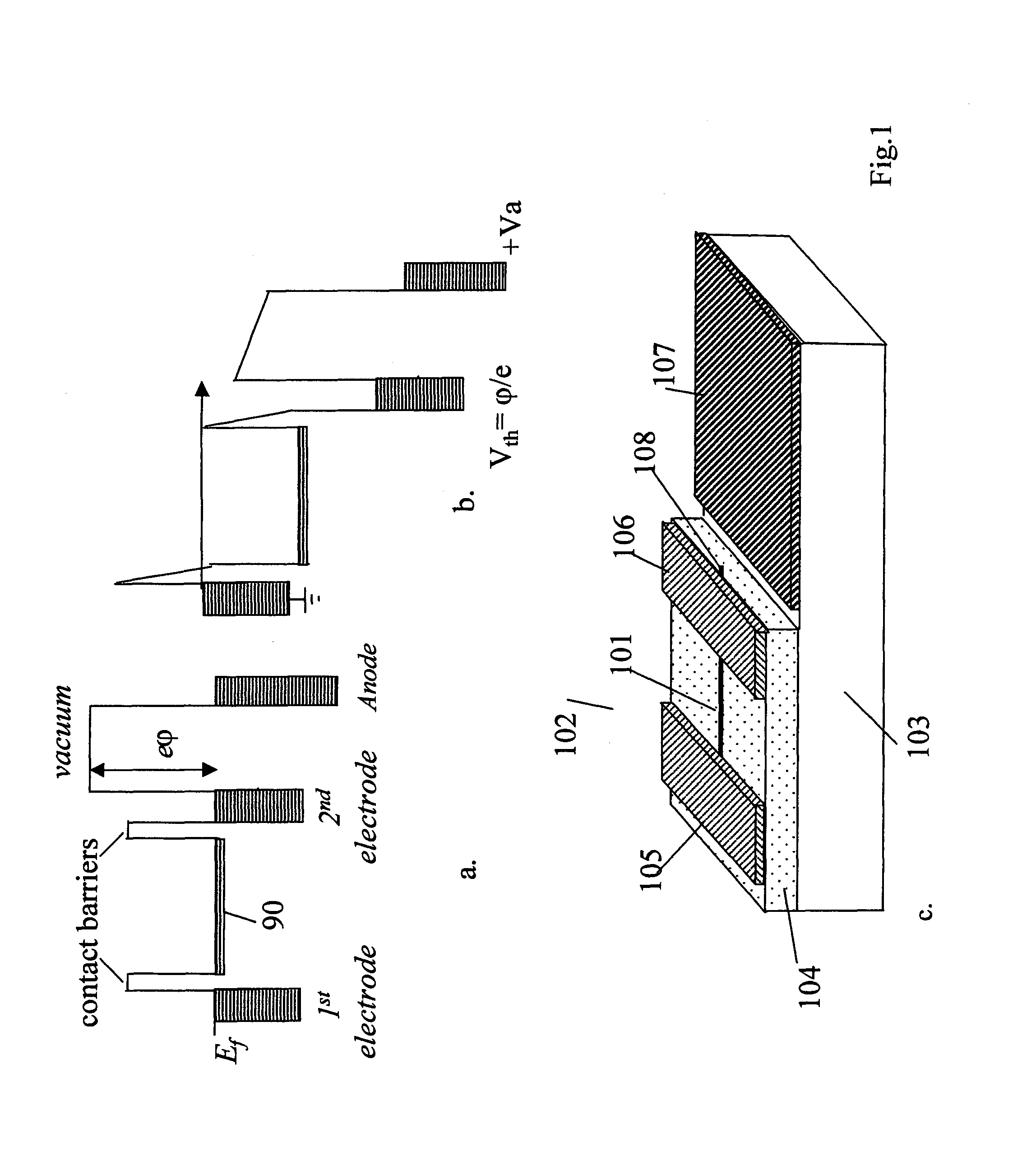

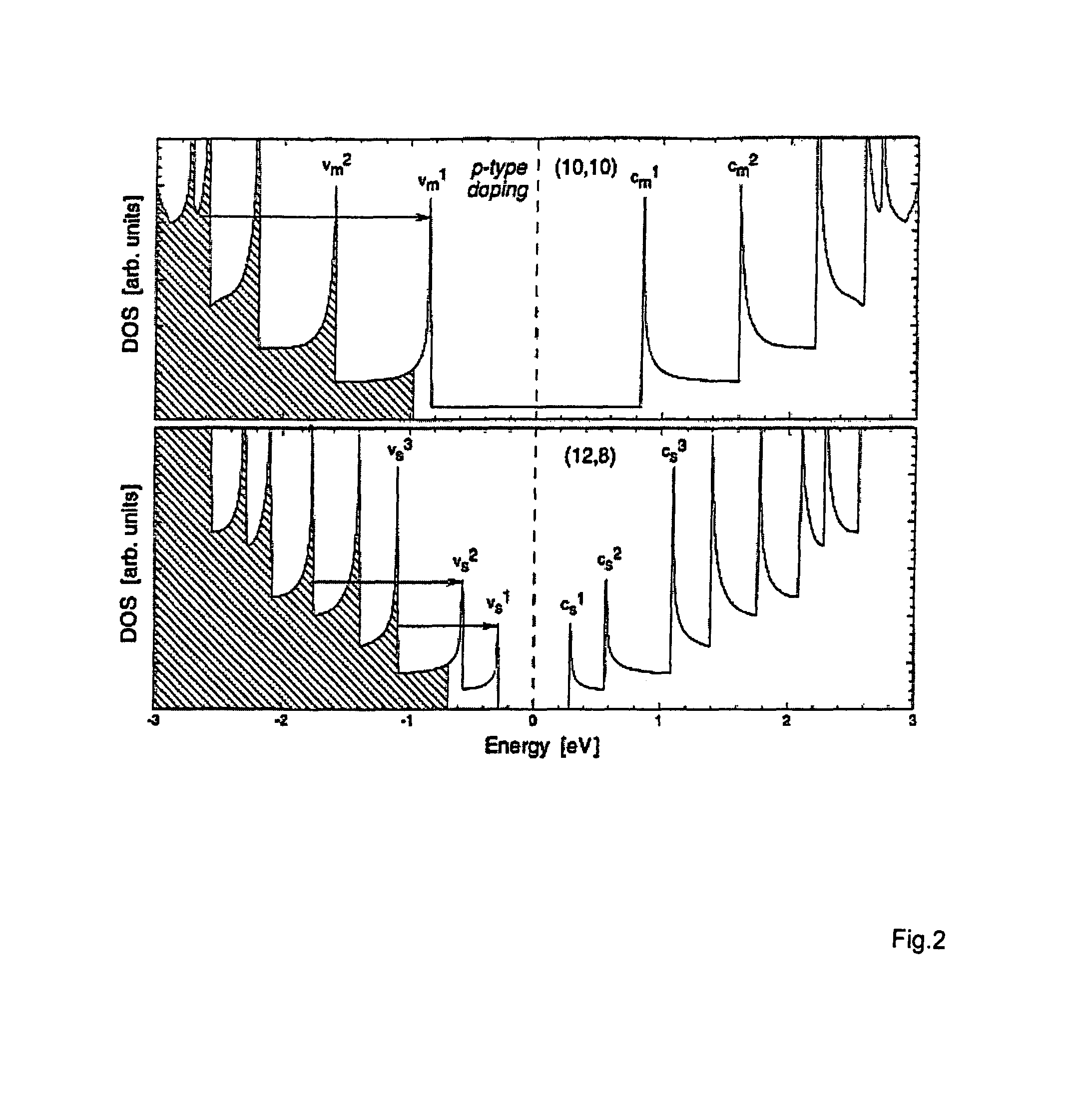

Nanotube array ballistic light emitting devices

InactiveUS20080218074A1Promote growthMaximum energy separationLaser detailsDischarge tube luminescnet screensHigh energyMetal electrodes

A new class of light emitting and laser diodes is disclosed wherein ballistic (without collisions) electron propagation along the nanotubes, grown normally to the substrate plane on the common metal electrode, provides conditions for the light emission from the nanotubes. The electrons, tunneling from the input contact into high energy states in the nanotubes, emit light via electron energy relaxation between the quantum energy levels existing in the nanotubes due to quantum size effect.In the disclosed devices, planar layer deposition technology is used to form a diode structure with two electrodes attached to the nanotubes ends.

Owner:NANO ELECTRONICS & PHOTONIC DEVICES & CIRCUITS

Making method and application of TiO2-CdSe nanocomposite photoelectric biosensor

InactiveCN104316460AImprove thermal stabilityGood biocompatibilityMaterial analysis by electric/magnetic meansMaterial analysis by optical meansHousekeeping geneQuantum dot

The invention elates to a making method and an application of a TiO2-CdSe nanocomposite photoelectric biosensor, and belongs to the technical field of biological detection sensors. A TiO2-CdSe complex is used as a photoelectric beacon substance, and a CdSe quantum dot enhances the photoelectric performances of TiO2 due to its quantum size effect, dielectric effect and surface effect in order to realize the sensitive, specific and rapid detection of body tissue target DNA and its housekeeping gene. The sensor made in the invention has the advantages of simple apparatus, low cost, easy miniaturization and integration, and easy popularization.

Owner:UNIV OF JINAN

Process for synthesizing high molecular nanometer composite material with pressure-sensitive performance and use

InactiveCN101311217AEfficient productionImprove performanceQuantum size effectSemiconductor technology

The invention relates to a synthetic technology for a macromolecular nano-composite with pressure-sensitive characteristic, which is used for preparing a pressure-sensitive element with high performance and high precision. The materials with the following weight percent are uniformly mixed to prepare the uniform macromolecular nano-composite: 20 percent to 40 percent of metal nanometer material, 10 percent to 30 percent of semiconductor ceramic nanometer material and 40 percent to 70 percent of macromolecular base material; wherein, the grain diameter of the metal nanometer material and the semiconductor ceramic nanometer material is 10nm to 500nm. The synthetic technology has the positive effect that metal nanometer powder and semi-conducting ceramic nanometer powder are fully mixed with the macromolecular material to form uniform homogeneous phrase, and the surface effect and the quantum size effect of the nanometer material are used for forming macroscopical pressure-sensitive effect. The technology for combining the macromolecular nano-composite, a circuit board and a semiconductor can efficiently produce various pressure-sensitive units; the performance of the product is highly reliable and the production cost is only a fraction of the traditional method.

Owner:上海思麦电子有限公司

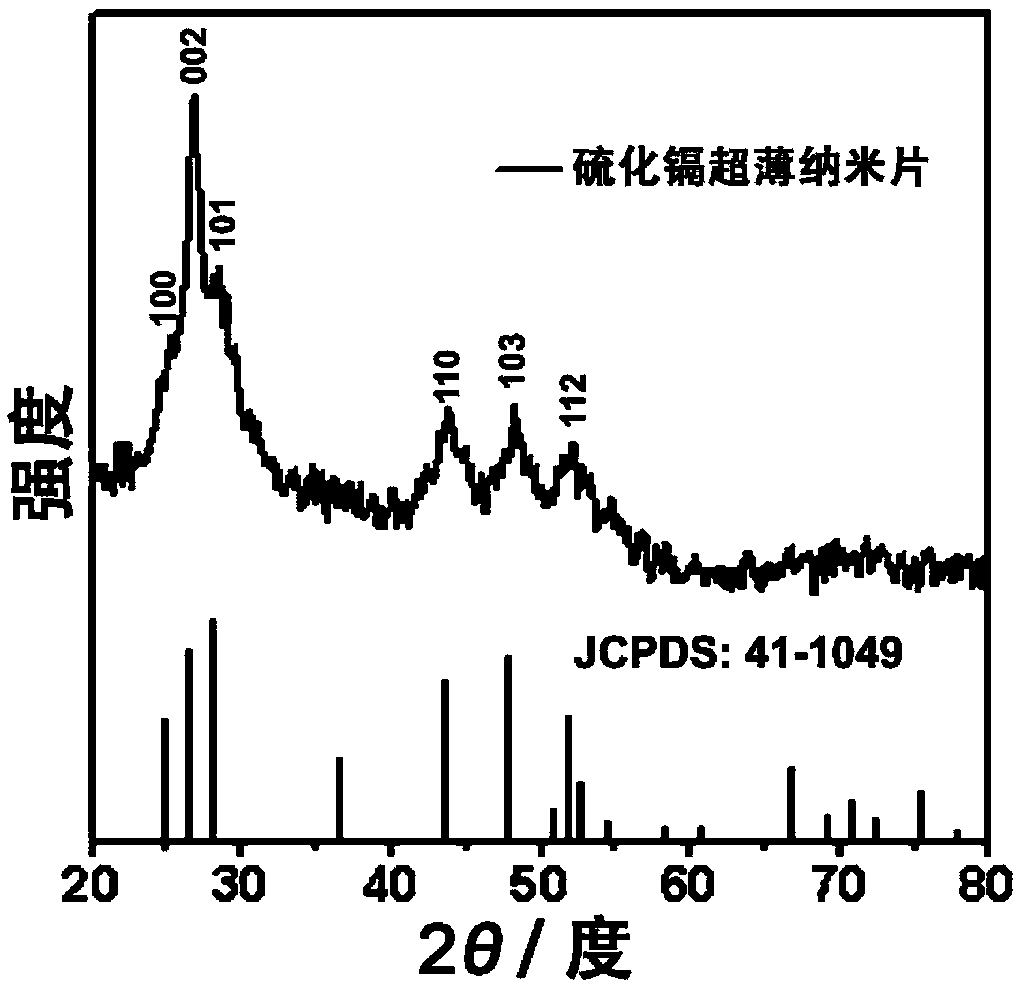

Cadmium sulfide ultrathin nanometer flaky material preparation method and application thereof

InactiveCN106698500AHigh purityLow costPhysical/chemical process catalystsCadmium sulfidesTwo stepCadmium sulfide

The invention discloses a cadmium sulfide ultrathin nanometer flaky material preparation method and application thereof. The preparation method comprises the steps of using cadmium chloride, powdered sulfur and diethylene triamine as raw materials to prepare a cadmium sulfide-amine hybridized nanosheet; then mixing the nanosheet, L-cysteine, water and the diethylene triamine to obtain uniform-distribution cadmium sulfide ultrathin nanometer flaky material water solution under an ultrasonic effect. A nanometer flaky material disclosed by the invention has the size of 100 to 300 nanometers, and the thickness of 3 to 5 nanometers. A two-step synthesizing method of the cadmium sulfide ultrathin nanometer flaky material disclosed by the invention has the characteristics of low cost, low synthesizing temperature, high product purity, ultrathin nanosheet, certain quantum size effect, stable structure and obvious advantage on phototcatalytic hydrogen production.

Owner:TIANJIN UNIV

High Speed Optical Tilted Charge Devices And Methods

ActiveUS20130126825A1Reduce heatReduce surface recombinationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureQuantum size effect

A method for producing optical signals with improved efficiency, including the following steps: providing a layered semiconductor structure that includes a substrate, a semiconductor collector region of a first conductivity type, a semiconductor base region of a second conductivity type disposed on the collector region, and a semiconductor emitter region of the first semiconductor type disposed as a mesa over a portion of a surface of the base region; providing, in the base region, at least one region exhibiting quantum size effects; providing collector, base, and emitter electrodes, respectively coupled with the collector, base and emitter regions; providing a tunnel barrier layer over at least the exposed portion of the surface of the base region; and applying signals with respect to the collector, base, and emitter electrodes to produce optical signals from the base region.

Owner:QUANTUM ELECTRO OPTO SYST

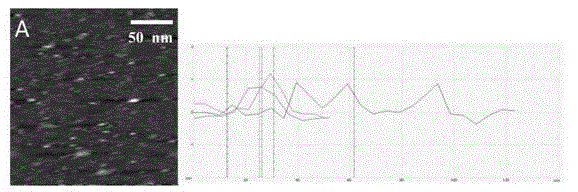

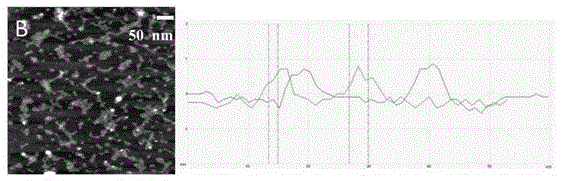

Prepn process of low temperature double ion beam sputtered multilayer Ge/Si film with self-organized Ge quantum dots

InactiveCN1974837ALow densitySmall sputtering rateVacuum evaporation coatingSputtering coatingSurface strainIntegrated circuit

The preparation process of low temperature double ion beam sputtered multilayer Ge / Si film with self-organized Ge quantum dots adopts Ar as the work gas and two ion beam sputtering guns, and features that at the conditions of work chamber background pressure lower than 3.0x10<-4> Pa, the substrate temperature of 200-400 deg.c, and work gas (Ar) pressure of (1.0-4.0)x10<-2> Pa, Si space layer and Ge quantum dot layer are deposited alternately on the Si substrate material by means of double ion beam sputtering technology. The surface strain potential field effect the previous Ge quantum dot layer generates is utilized in realizing the ordered growth of the Ge quantum dots in the subsequent layer, and this raises the film surface smoothness and filming quality and results in multilayer Ge / Si film with self-organized Ge quantum dots in high density and homogeneous size and quantum size effect. The present invention is compatible with IC technology, low in production cost and easy for industrial production.

Owner:YUNNAN UNIV

Light emitting and lasing semiconductor devices and methods

ActiveUS7953133B2Avoid injection and transportMaximize the stimulated recombination (emissionLaser active region structureLaser cooling arrangementsElectron flowQuantum size effect

A two terminal semiconductor device for producing light emission in response to electrical signals, includes: a terminal-less semiconductor base region disposed between a semiconductor emitter region and a semiconductor collector region having a tunnel junction adjacent the base region; the base region having a region therein exhibiting quantum size effects; an emitter terminal and a collector terminal respectively coupled with the emitter region and the collector region; whereby application of the electrical signals with respect to the emitter and collector terminals, causes light emission from the base region. Application of the electrical signals is operative to reverse bias the tunnel junction. Holes generated at the tunnel junction recombine in the base region with electrons flowing into the base region, resulting in the light emission. The region exhibiting quantum size effects is operative to aid recombination.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

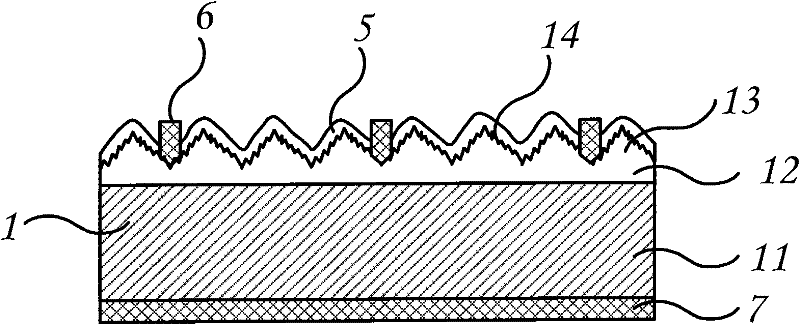

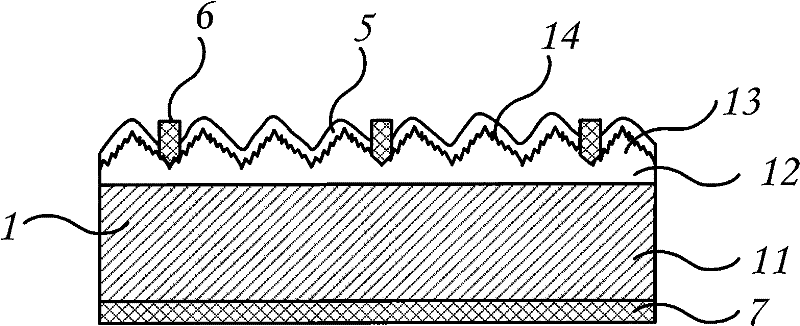

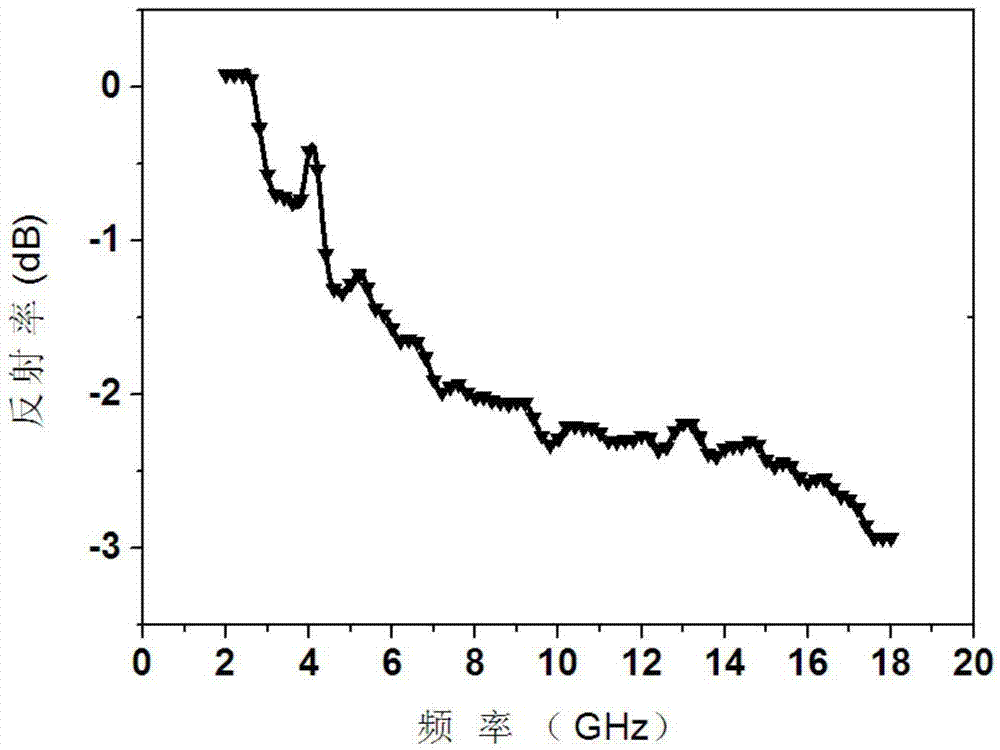

a solar cell

InactiveCN102270688AImprove efficiencyFinal product manufacturePhotovoltaic energy generationNano siliconSurface roughness

The present invention involves a solar cell. The solar cell includes a silicon wafer 1, and the reflux layer 12 prepared by the Silicon 1 on the Silicon 1, the velvet 13 prepared on the silicon tape 1, use the etching method on the velvet 13The upper -made silicon nanometer layer 14, the passivation layer 5, the upper electrode grid line 6 and the lower electrode 7.Silicon 1 does not change the type of conductivity in the heat diffusion and the PN knot required to form a solar cell.The surface of the solar cell of this structure is the surface 13, and the silicon nano layer 14 is carved on it.The absorption and utilization rate of ultraviolet light, thereby improving the efficiency of solar cells.

Owner:刘爱民 +2

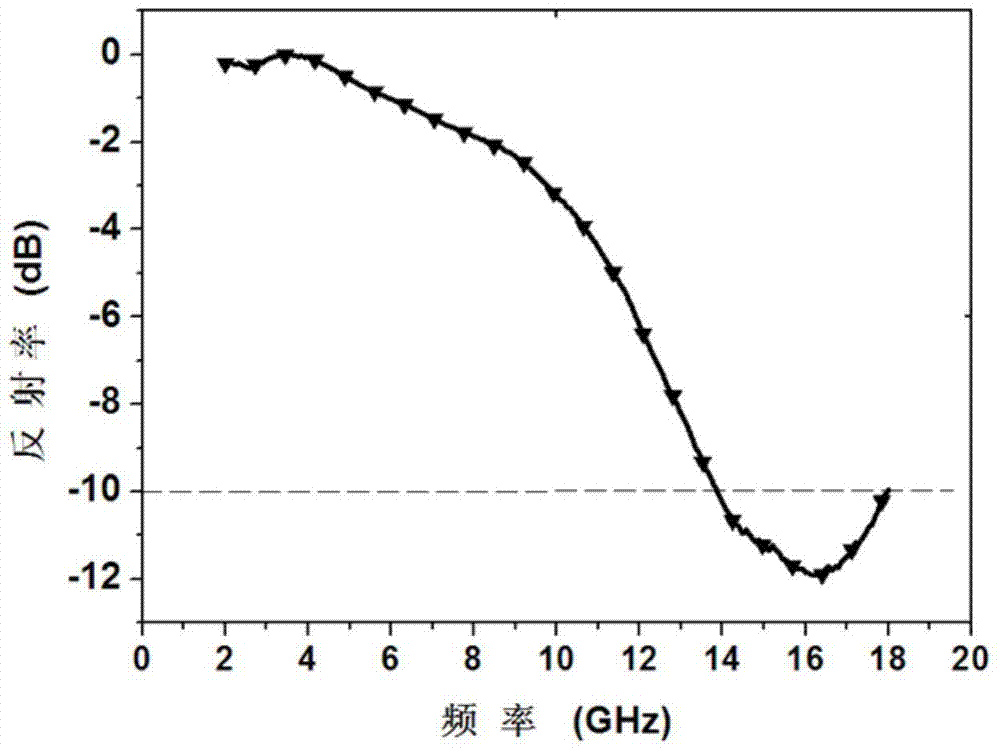

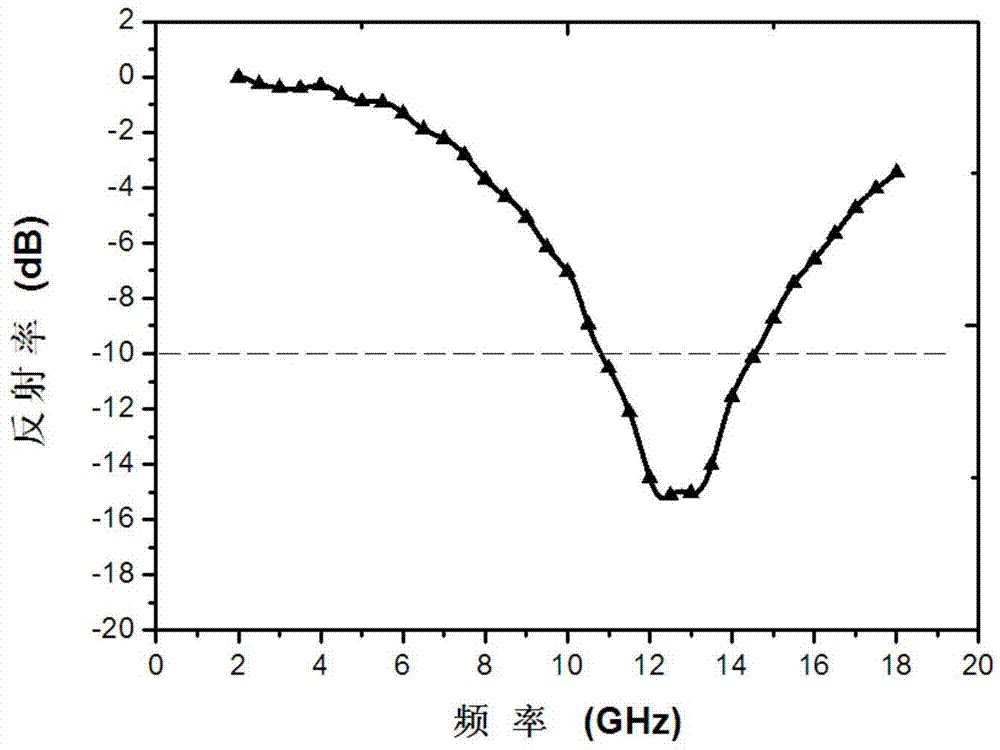

Coated wave-absorbing material prepared from nano-graphite powder and preparation method of coated wave-absorbing material

ActiveCN104845044ACorrosion resistantWith absorbing frequency bandwidthOther chemical processesGranularityQuantum size effect

The invention discloses a coated wave-absorbing material prepared from nano-graphite powder and a preparation method of the coated wave-absorbing material. The material comprises a wave absorber and an adhesive, the wave absorber refers to the nano-graphite powder with the weight percent of 1%-75%, the adhesive refers to at least one of resin, rubber and plastics, and the weight percent of the adhesive is 25%-99%. The coated wave-absorbing material has the advantages that the nano-graphite powder is small in specific gravity, the tap density of the nano-graphite powder is 0.6-1.0g / cm<3>, the nano-graphite powder is fine in corrosion resistance, can resist corrosion of seawater and various acid-alkali media and has excellent wave-absorbing performance by the aid of small-size effect, surface effect and quantum size effect, wave-absorbing materials at different wavebands can be obtained by adjusting the granularity, the mixing concentration and the coating thickness of the wave absorber, and the wave-absorbing material is light in weight, thin in coating, fine in dispersing performance, strong in wave-absorbing performance, stable and controllable in quality, simple and easy in preparation process and can meet different invisible requirements.

Owner:HEFEI SIRUI NEW MATERIAL TECH CO LTD

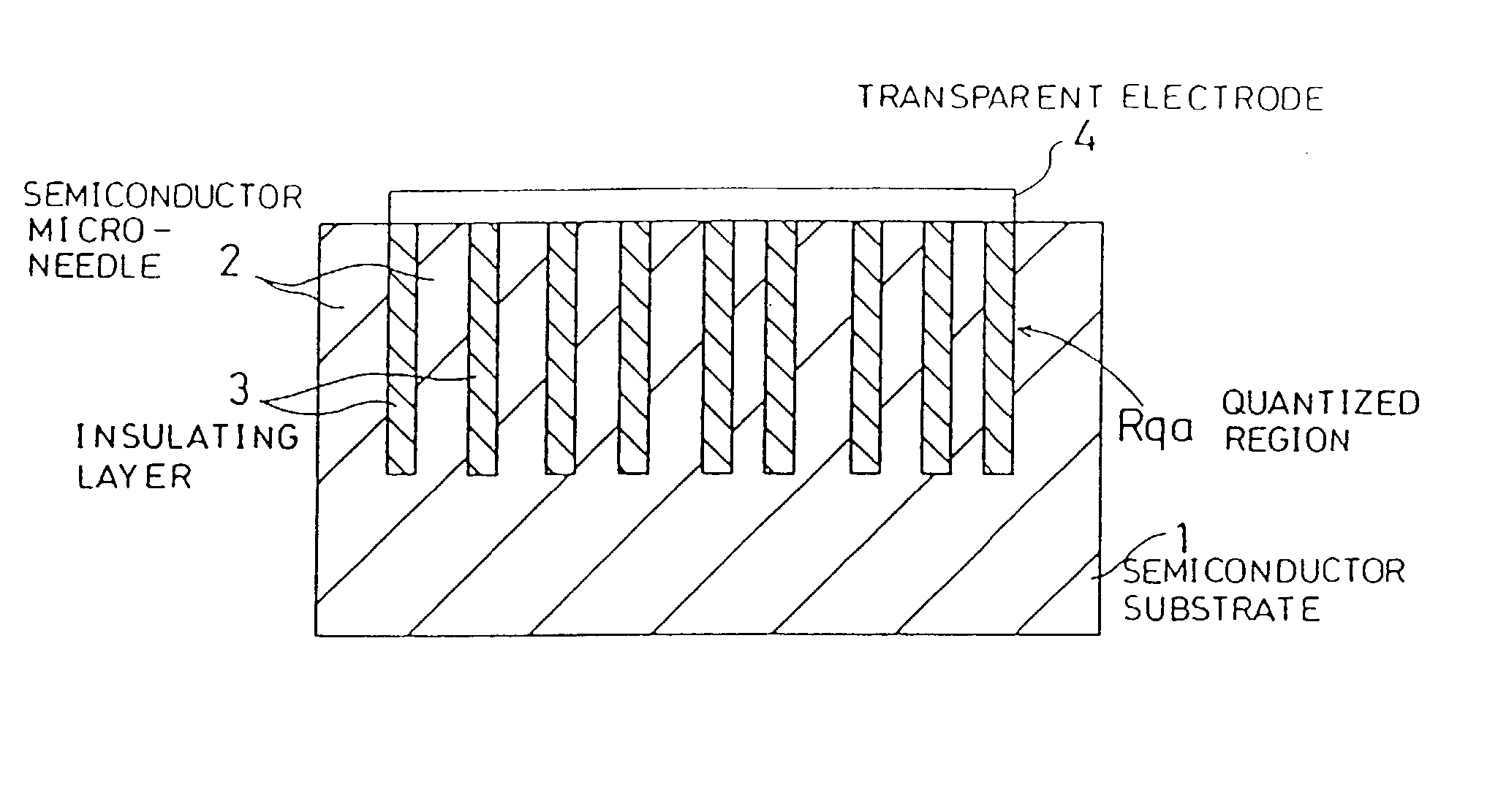

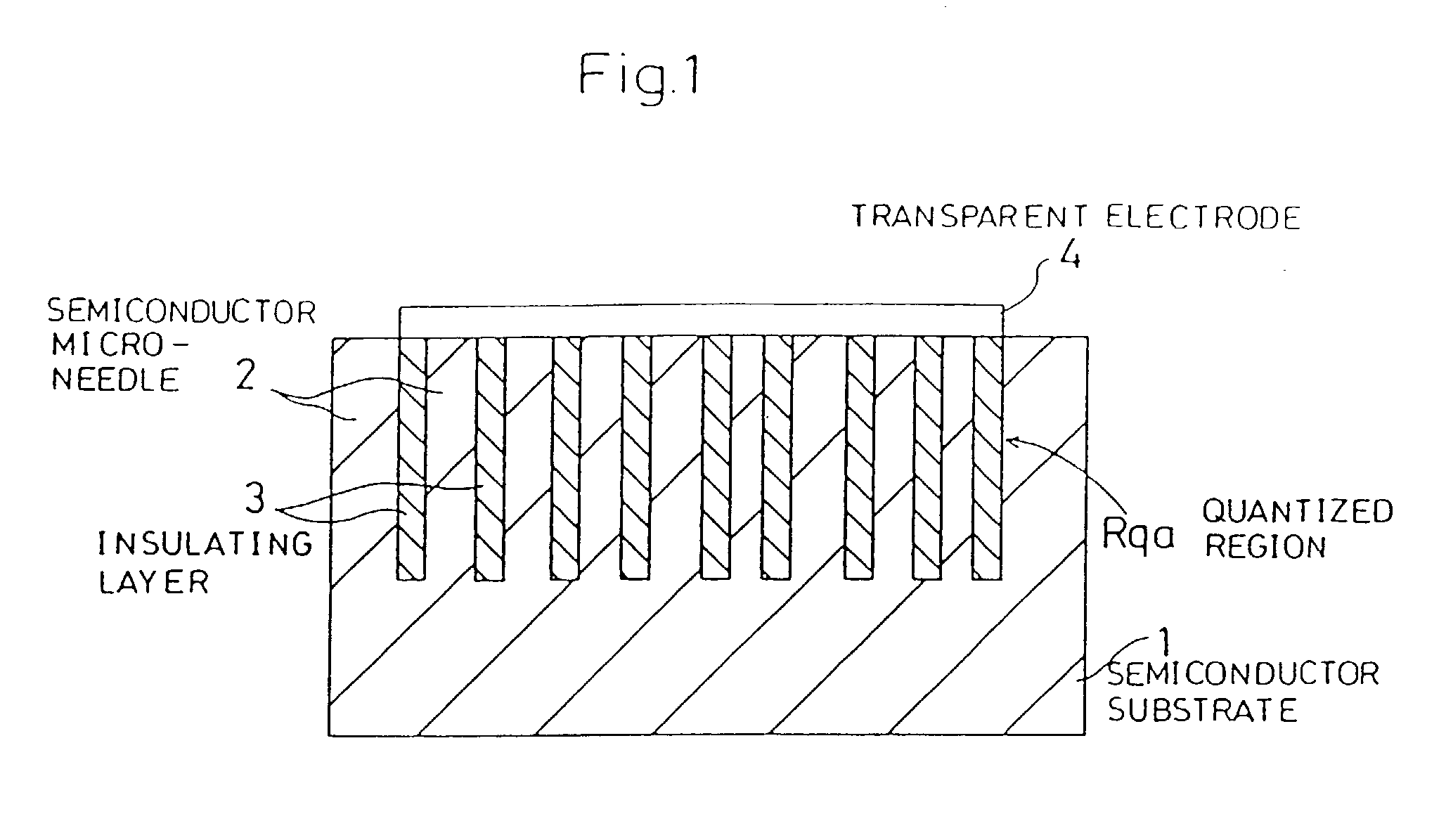

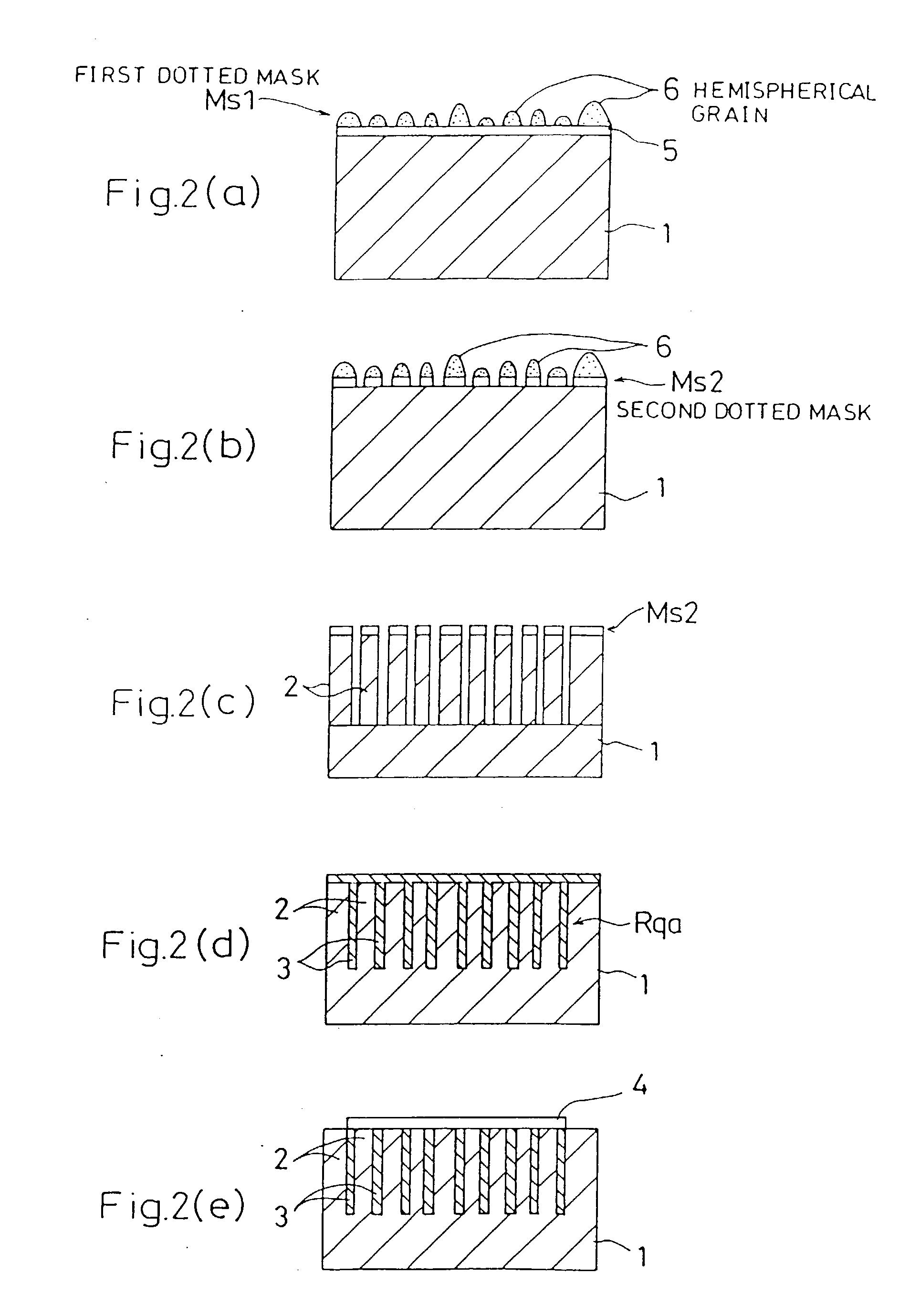

Aggregate of Semicnductor micro-needles and method of manufacturing the same, and semiconductor apparatus and method of manufacturing the same

InactiveUS20030057451A1Easy to manufactureEnhancing quantum size effectElectrophonic musical instrumentsFinal product manufactureInformation processingQuantum size effect

On a silicon substrate is formed a silicon dioxide film and then hemispherical grains made of silicon, each having an extremely small diameter, are deposited thereon by LPCVD. After annealing the hemispherical grains, the silicon dioxide film is etched using the hemispherical grains as a first dotted mask, thereby forming a second dotted mask composed of the silicon dioxide film. The resulting second dotted mask is used to etch the silicon substrate to a specified depth from the surface thereof, thereby forming an aggregate of semiconductor micro-needles. Since the diameter of each of the semiconductor micro-needles is sufficiently small to cause the quantum size effects as well as has only small size variations, remarkable quantum size effects can be obtained. Therefore, it becomes possible to constitute a semiconductor apparatus with a high information-processing function by using the aggregate of semiconductor micro-needles (quantized region).

Owner:PANASONIC CORP

Nanotube array ballistic light emitting devices

InactiveUS7728333B2Promote growthMaximum energy separationLaser detailsDischarge tube luminescnet screensHigh energyMetal electrodes

A new class of light emitting and laser diodes is disclosed wherein ballistic (without collisions) electron propagation along the nanotubes, grown normally to the substrate plane on the common metal electrode, provides conditions for the light emission from the nanotubes. The electrons, tunneling from the input contact into high energy states in the nanotubes, emit light via electron energy relaxation between the quantum energy levels existing in the nanotubes due to quantum size effect.In the disclosed devices, planar layer deposition technology is used to form a diode structure with two electrodes attached to the nanotubes ends.

Owner:NANO ELECTRONICS & PHOTONIC DEVICES & CIRCUITS

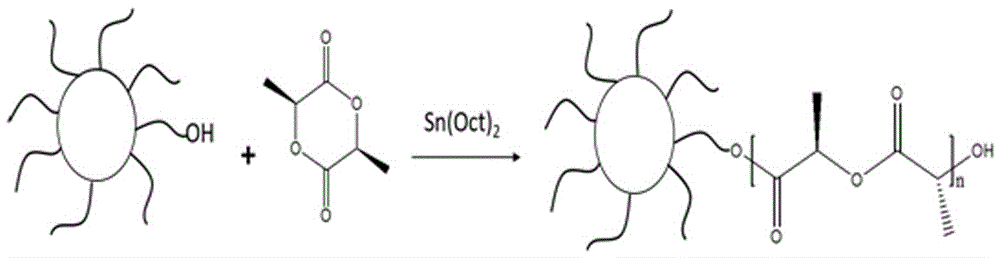

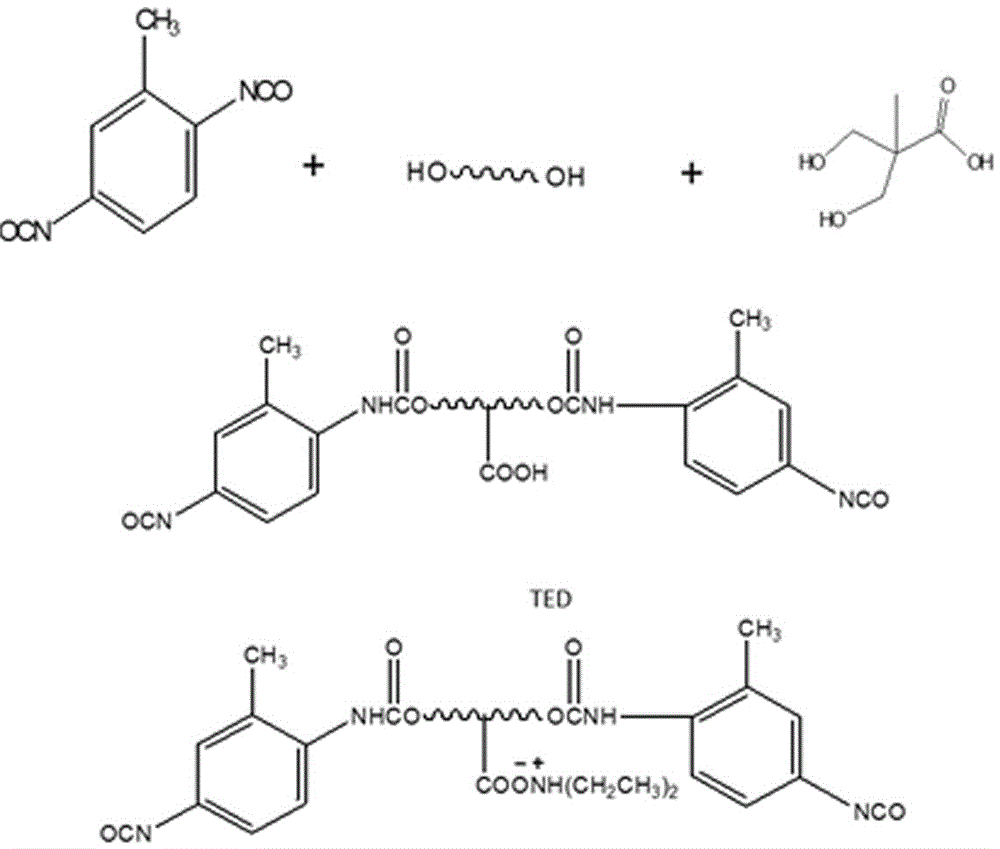

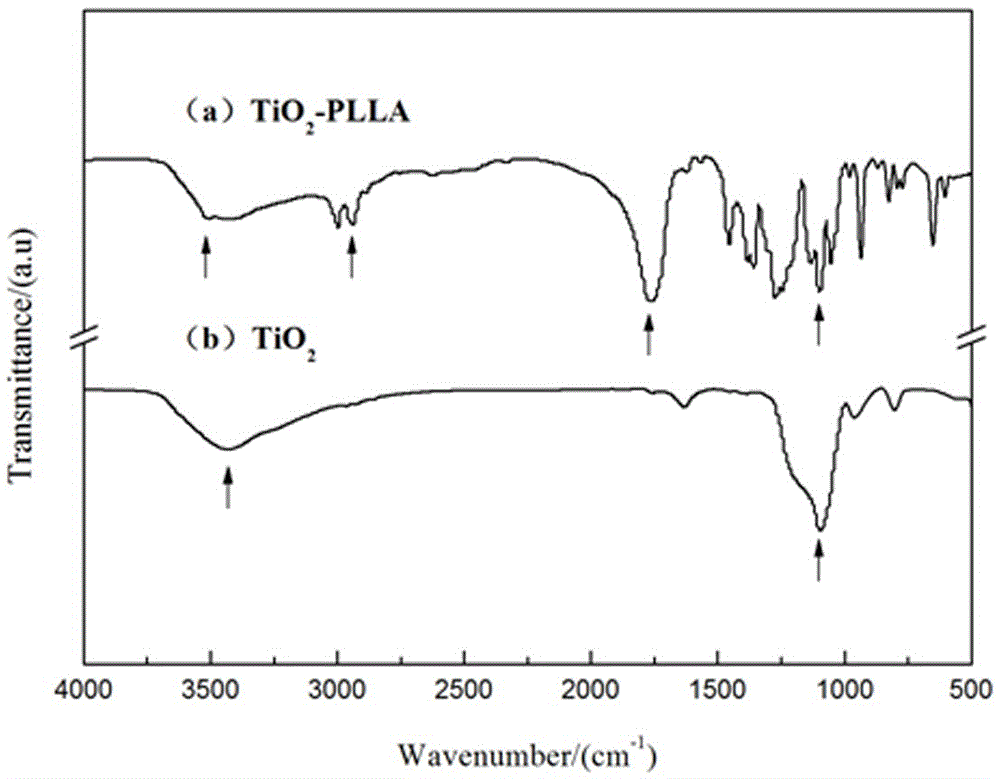

Preparation method of degradable waterborne polyurethane paint and product

The invention discloses a method for preparing degradable waterborne polyurethane paint. The method comprises the steps that waterborne polyurethane is modified by nano titanium dioxide, wherein the water resistance, the mechanical property and the like of waterborne polyurethane can be improved through the special characters such as the surface and interface effect, the quantum size effect and the macroscopic quantum tunneling effect of the titanium dioxide particles, and meanwhile attachment of microorganisms to the surface of a coating can be effectively reduced through the antibacterial property of nano titanium dioxide; polylactic acid is connected to the surface of nano titanium dioxide, and then the waterborne polyurethane coating with the biodegradablity is prepared. According to the method, a -NCO terminal is prepared through the connection function of a toluene diisocynate functional group -NCO to be connected with a titanium dioxide-polylactic acid composite coating, the purpose of modifying waterborne polyurethane is achieved, polylactic acid is soft in main chain and can be easily catabolized by microorganisms in the natural world, a decomposition product is free of pollution, and the microorganisms attached to the surface are effectively removed; nano titanium dioxide has the excellent antibacterial and bactericidal characteristics, attachment of fouling organisms is greatly reduced, and the surface cleanliness of the coating is kept.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com