Process for synthesizing high molecular nanometer composite material with pressure-sensitive performance and use

A nano-composite material and synthesis process technology, applied in the field of polymer nano-composite materials, can solve the problems of high additional capacitance, less impact resistance, short life, etc., and achieve the effect of highly reliable product performance and efficient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

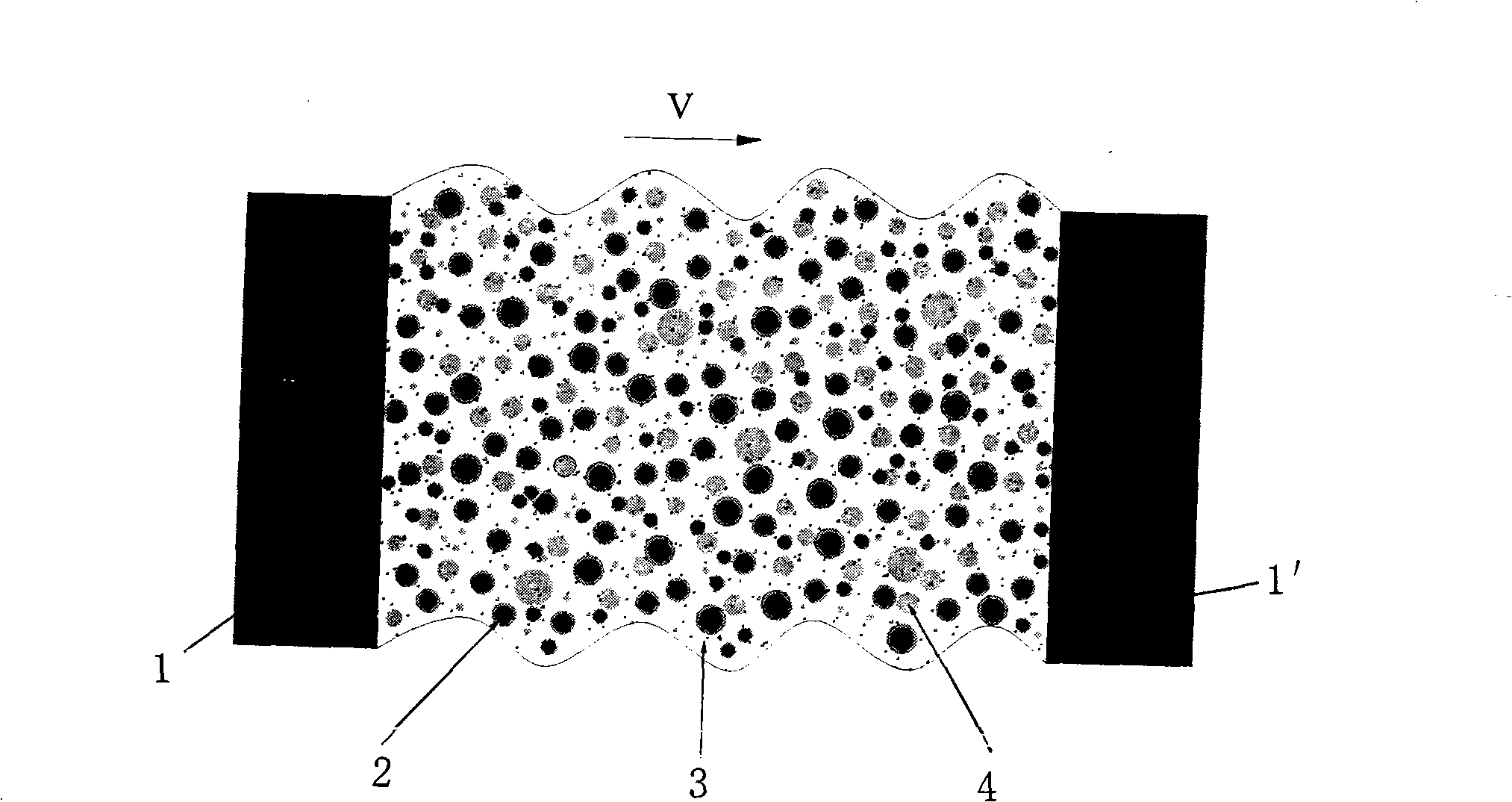

Image

Examples

Embodiment 1

[0019] Metal nanomaterials and semiconductor ceramic nanomaterials are uniformly blended with polymer matrix materials to make homogeneous polymer nanocomposites, and the weight percent of each component is:

[0020] Metal nanomaterials Nickel (particle size 150nm) 23%

[0021] Semiconductor ceramic nanomaterials Zinc oxide (particle size 120nm) 12%

[0022] Polymer matrix material Epoxy resin 65%

[0023] Add about 5% curing agent T31 of the total weight in the above-mentioned composite material slurry, stir for more than 5 hours, stop stirring after its viscosity gradually increases, put it into a container for use, and use it to make polymer nanocomposite materials. Sensitive components. Use the method disclosed in Chinese Patent Application No. 200810032677.8 to print it on the etched PCB board, and heat it to cure it. Press the printed circuit board on a PCB board with etched graphics, and make graphics on the entire board after compounding, lead the electrodes of the ...

Embodiment 2

[0027] Operate in the same manner as in Example 1, and each component and percentage by weight thereof are changed into:

[0028] Metal nanomaterials nickel + copper (both particle sizes are 120nm) 25%

[0029] Semiconductor ceramic nanomaterials Zinc oxide + silicon carbide (particle size 100nm) 20%

[0030] Polymer matrix material Epoxy resin 55%

[0031] The prepared nano-polymer composite slurry is used to make polymer nano-composite pressure-sensitive elements, the distance between electrodes is 0.1mm, the pressure-sensitive breakdown voltage Vbr is 200V, and the pressure-sensitive clamping voltage Vc is 45V.

Embodiment 3

[0033] Operate in the same manner as in Example 1, and each component and percentage by weight thereof are changed into:

[0034] Metal nanomaterials Nickel (particle size 120nm) 35%

[0035] Semiconductor ceramic nanomaterials Zinc oxide (particle size 100nm) 20%

[0036] Polymer matrix material Silicone resin 45%

[0037] The prepared nano-polymer composite slurry is used to make polymer nano-composite pressure-sensitive elements, the distance between electrodes is 0.05mm, the pressure-sensitive breakdown voltage Vbr is 300V, and the pressure-sensitive clamping voltage Vc is 80V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com