Hydrotalcite quantum dot electrocatalyst, preparation method thereof, application of hydrotalcite quantum dot electrocatalyst in electrocatalytic decomposition of water to produce oxygen

A technology of electrocatalysts and quantum dots, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve low cost, simple process, and superior catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

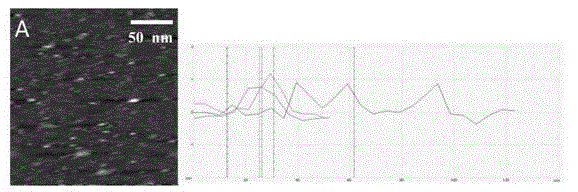

[0049] 1. Preparation of NiCo-LDHs hydrotalcite quantum dot electrocatalyst:

[0050] Preparation of microemulsion: Add 5ml of isopropanol, 8ml of oleylamine, and 4ml of deionized water into the flask, stir until the solution is uniform, and obtain a microemulsion environment; add 0.0048mol of Ni(NO 3 ) 2 ·6H 2 O and 0.0024mol of Co(NO 3 ) 3 9H 2 O was added to the microemulsion prepared above, and after the salt was dissolved, the crystallization water was heated at 100°C for 27 hours.

[0051] After the reaction was completed, the product was filtered with suction, washed three times with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, washed once with absolute ethanol, centrifuged, and dried at 60°C for 14 hours to obtain NiCo-LDHs Quantum dot precursor products.

[0052] The above precursor products were dispersed into formamide, sonicated by a high-power ultrasonic instrument for 4 hours, centrifuged at low speed to remove the bottom sedi...

Embodiment 2

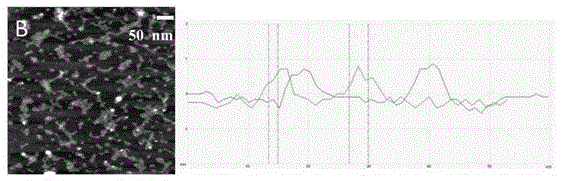

[0059] Preparation of NiFe-LDH hydrotalcite quantum dot electrocatalyst:

[0060] Preparation of microemulsion: Add 3ml of isopropanol, 6ml of oleylamine dioctylamine, and 5ml of deionized water into the flask, and stir until the solution is uniform; add 0.004mol of Ni(NO 3 ) 2 ·6H 2 O and 0.002mol Fe(NO 3 ) 3 9H 2 O was added to the microemulsion prepared above, and after the salt was dissolved, the crystallization water was heated at 80°C for 20 hours.

[0061] After the reaction was completed, the product was filtered with suction, washed three times with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, washed once with absolute ethanol, centrifuged, and dried at 90°C for 6 hours to obtain NiFe-LDHs Quantum dot precursor products.

[0062] Disperse the above precursor product into N,N-dimethylformamide, use a high-power ultrasonic instrument to sonicate for 6 hours, and centrifuge at low speed to remove the bottom sediment, and then perform ...

Embodiment 3

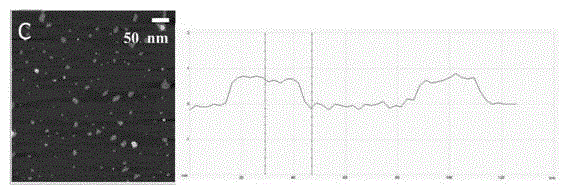

[0067] Preparation of NiTi-LDH hydrotalcite quantum dot electrocatalyst:

[0068] Preparation of microemulsion: Add 3ml of isopropanol, 5ml of oleylamine N,N-dimethyltetradecylamine, and 7ml of deionized water into the flask, stir until the solution is uniform; add 0.006mol of Ni(NO 3 ) 2 ·6H 2 O and 0.003 mil of TiCl4 were added to the microemulsion prepared above, and after the salt was dissolved, the crystallization water was heated at 120° C. for 15 hours.

[0069] After the reaction was completed, the product was suction-filtered, washed twice with a mixed solution of deionized water and ethanol with a volume ratio of 1:1, washed once with absolute ethanol, centrifuged, and dried at 70°C for 10 h to obtain NiTi-LDHs Quantum dot precursor products.

[0070] Disperse the above precursor products into N, N-dimethylformamide, use a high-power ultrasonic instrument to sonicate for 5 hours, and centrifuge at low speed to remove the bottom sediment, and then perform high-spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com