Construction method of graded broken stone and cement composite packing layer

A technology of graded gravel and construction method, applied in ballast layer, infrastructure engineering, roads, etc., can solve problems such as affecting normal use function, shrinkage cracks in filling layer, etc., to reduce roadbed diseases, simple and convenient operation, and improve The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

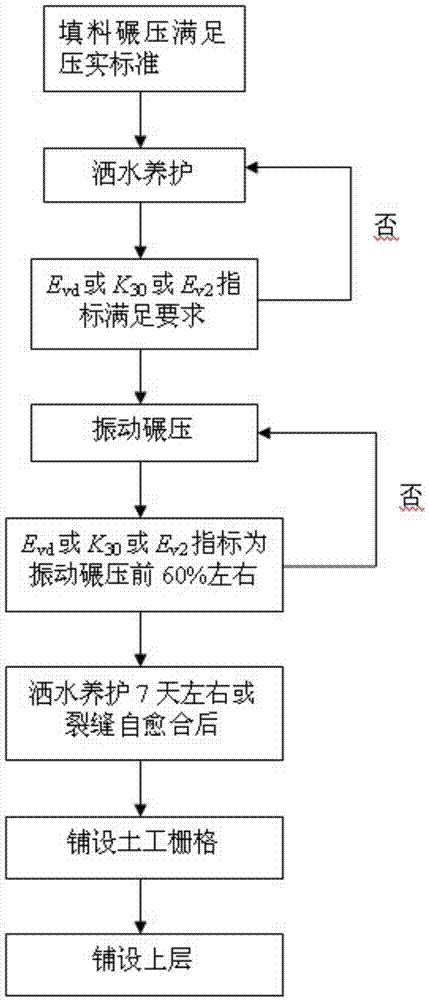

[0030] After the filling and rolling of graded crushed stone mixed with cement filler meets the compaction standard (foundation coefficient K30≥190MPa / m and Evd≥55MPa), watering maintenance is carried out, and the dynamic deformation modulus Evd is detected one day later. When Evd≥80MPa (if If it is not satisfied, continue to maintain until the index requirements are met), use a compacted road roller to vibrate and compact the filling layer, so that the filling layer will produce network cracks, so as to eliminate the partial shrinkage caused by the drying shrinkage and temperature shrinkage of graded gravel mixed with cement Stress, to avoid the formation of severe shrinkage cracks. After each vibratory rolling, check the dynamic deformation modulus Evd. When the detection index is about 60% before vibratory rolling, stop rolling, sprinkle water to cover and maintain for 7 days or after the cracks are healed, lay geogrid on the filling layer, and carry out The upper layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com