Multi-level traveling wave thermoacoustic engine system for flue gas waste heat

A thermoacoustic engine and flue gas waste heat technology, which is applied in the direction of machines/engines, mechanical power generating mechanisms, mechanical equipment, etc., can solve problems such as the failure of the induction cooker to work normally, reduce the service life of the electromagnetic, and damage electronic components, etc., and achieve structural Compact, concentrated output, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

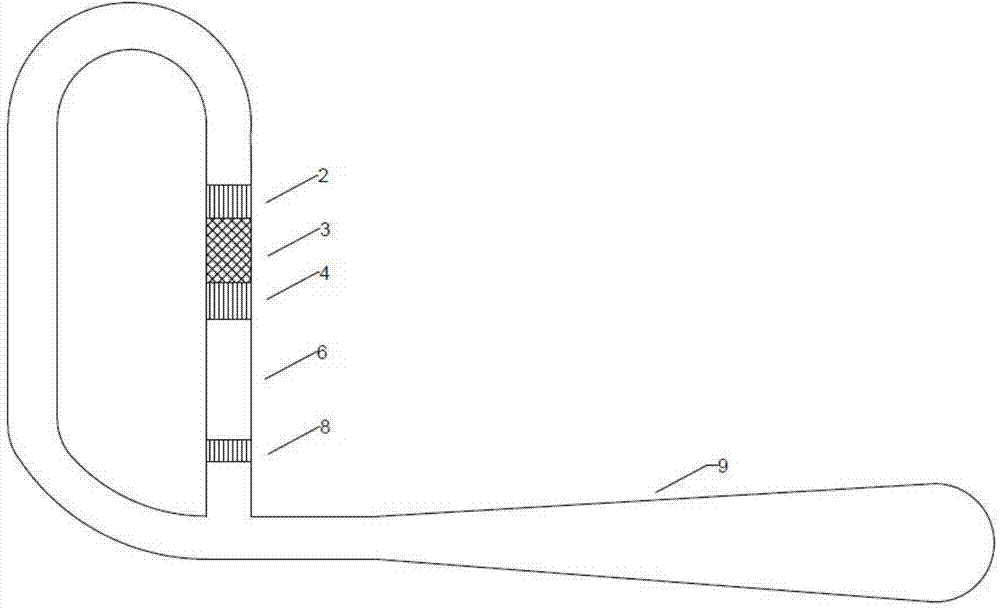

[0038] Such as image 3 As shown, the multi-stage traveling wave thermoacoustic engine system for the efficient utilization of flue gas exhaust heat provided by Embodiment 1 of the present invention includes three thermoacoustic engine units with the same structure and different sizes; each thermoacoustic engine unit passes through The resonant tubes 9 are connected end to end to form a loop; each thermoacoustic engine unit is composed of a DC suppressor 1, a main cooler 2, a regenerator 3, a heater 4, and a high-temperature end laminar fluidization element 5 connected in sequence. , heat buffer tube 6, room temperature end laminar fluidization element 7 and secondary cooler 8;

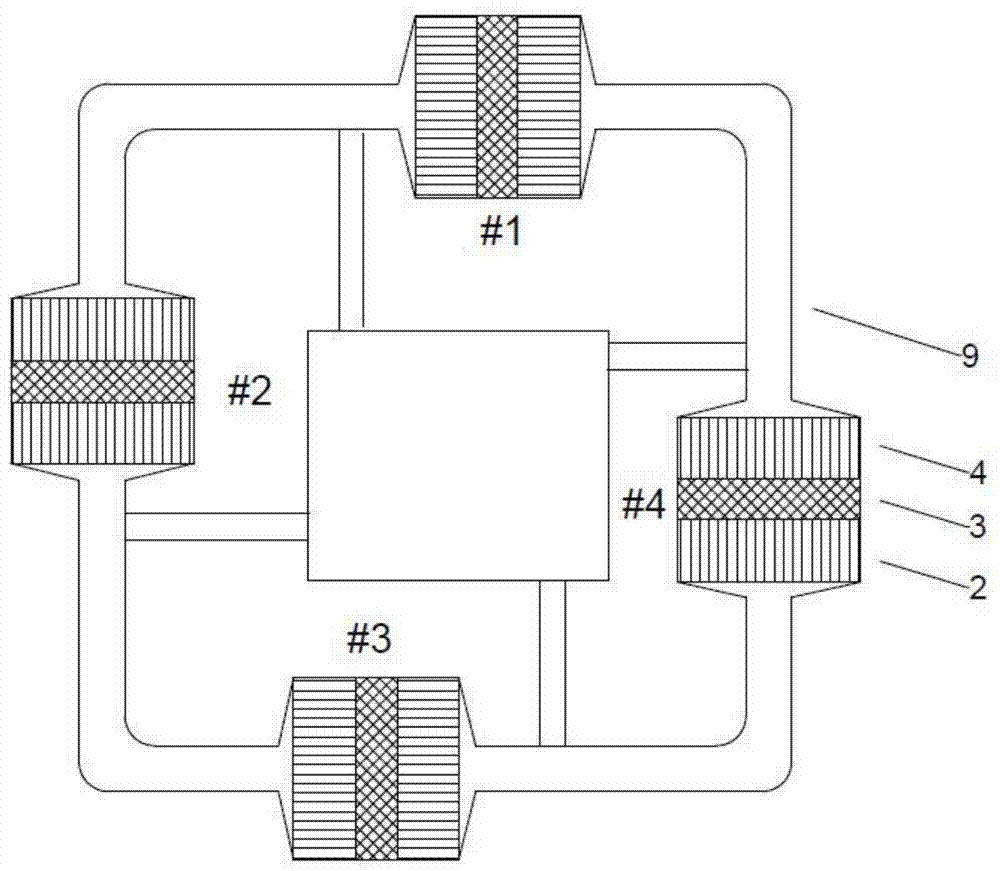

[0039] The diameters of #1 thermoacoustic engine unit, #2 thermoacoustic engine unit and #3 thermoacoustic engine unit decrease in turn, and they are distributed in the loop counterclockwise; the diameters of the resonance tubes 9 between them also decrease in turn; The load of the multi-stage travel...

Embodiment 2

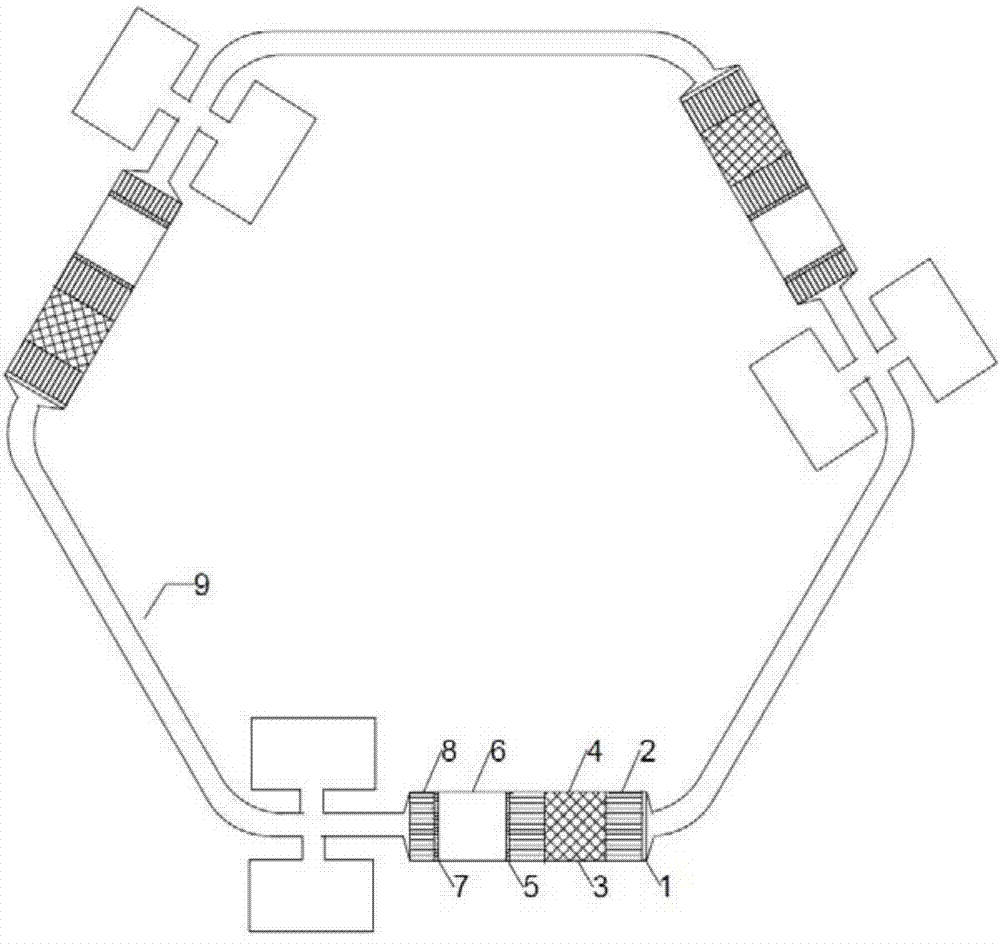

[0044] Figure 4 The multi-stage traveling wave thermoacoustic engine system for efficient utilization of flue gas waste heat provided by Embodiment 2 of the present invention is composed of 6 thermoacoustic engine units with the same structure and different sizes; each thermoacoustic engine unit passes through resonance tubes with different diameters 9 are connected end to end to form a loop; each thermoacoustic engine unit is composed of a DC suppressor 1, a main cooler 2, a regenerator 3, a heater 4, a high-temperature end laminar fluidization element 5, and a thermal buffer tube connected in sequence 6. Composed of room temperature end laminar fluidization element 7 and secondary cooler 8;

[0045] Among them, the size of #1 to #6 thermoacoustic engine units decreases in turn, and they are distributed in the loop counterclockwise; the diameter of the resonance tube between them also decreases in turn; the load of the multi-stage traveling wave thermoacoustic engine system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com