Waste heat recovery device for drying room and temperature control method thereof

A technology of waste heat recovery device and heat exchange device, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of large energy consumption, easy bonding and condensation, waste of heat energy, etc., and meet the exhaust temperature Requirements, improved heat recovery efficiency, simple cleaning and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

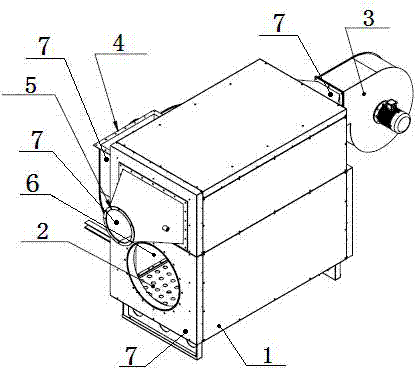

[0018] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a drying room waste heat recovery device includes a box body 1 and a heat exchange device. The heat exchange device is combined with the box body 1 through a heat exchange joint 2, and cold air is pumped into the heat exchange device. The heat exchange principle is used to absorb the heat of the exhaust gas flowing through the box body 1 .

[0019] Further, the heat exchange device is located on the upper part of the heat exchange joint 2, including the blower 3, the preheating chamber 6 and the air outlet joint 5, which are used to circulate the air that absorbs waste heat; the box 1 is located on the heat exchange joint 2. In the lower part, an exhaust fan 4 is arranged on one side of the box for the circulation of waste heat gas; the blower 3 and the exhaust fan 4 are controlled by frequency conversion; inside the box 1, there are 4 ports o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com