Method for forming transparent conductive film, and device for heating and drying thin-film

A transparent conductive film, heating and drying technology, applied to the device for coating liquid on the surface, the conductive layer on the insulating carrier, the circuit, etc., can solve the problems of easy bending, high manufacturing cost, difficult to apply the film, etc., to improve the conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

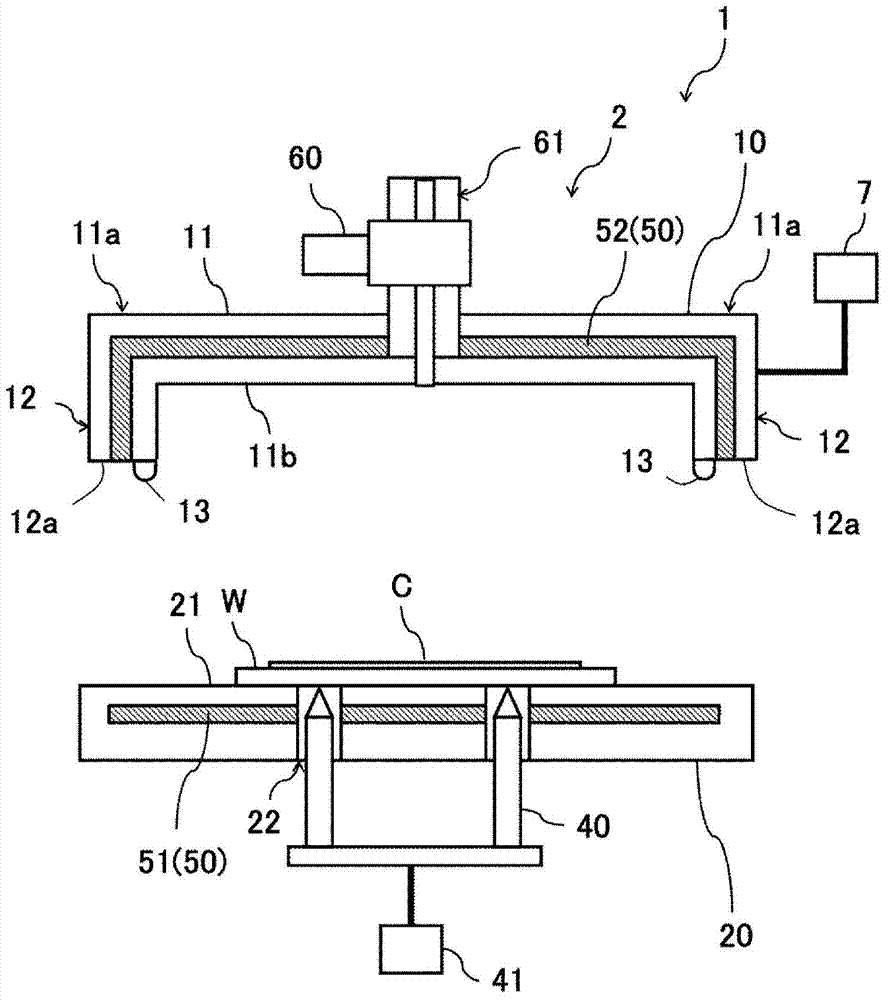

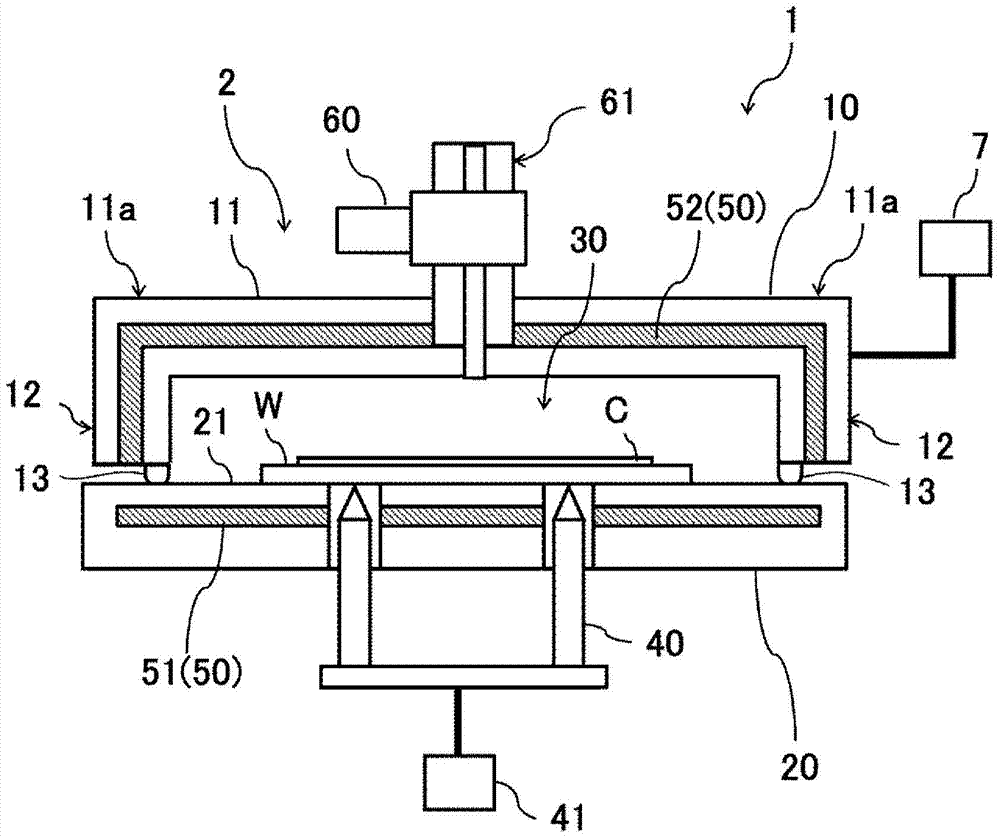

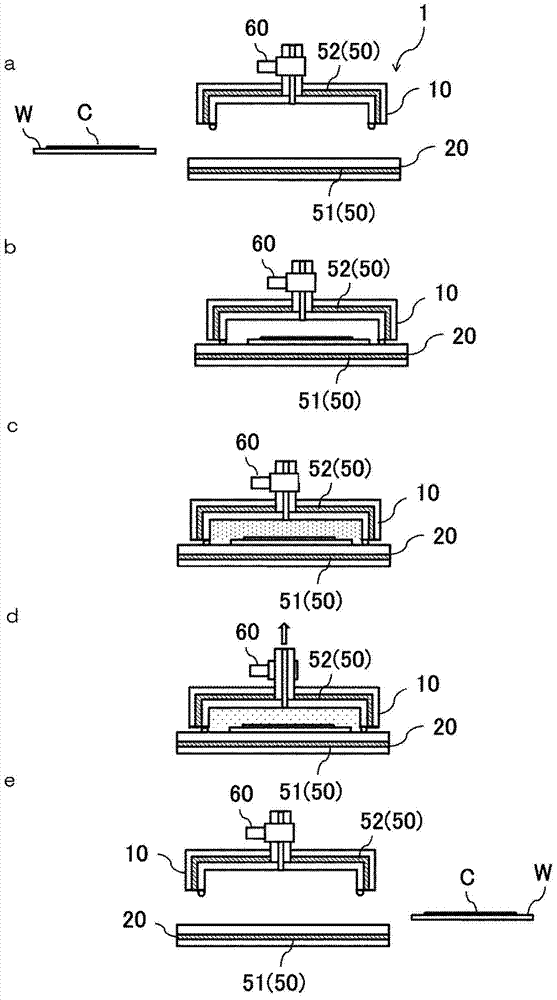

[0033] Next, an embodiment of the film heating and drying apparatus 1 of the present invention will be described. here, figure 1 It is a schematic diagram showing the open state of the chamber of the film heating and drying apparatus 1 in this embodiment, figure 2 It is a schematic diagram showing the closed state of the chamber of the film heating and drying apparatus 1 .

[0034] Such as figure 1 , figure 2 As shown, the thin film heating and drying apparatus 1 is an apparatus that dries the coating film C formed on the substrate W to be processed to form a transparent conductive film used in liquid crystals, organic EL, solar cells, and the like. That is, it is a device that applies a coating material obtained by dispersing a conductive polymer material of polyethylenedioxythiophene / polystyrene sulfonic acid (PEDOT / PSS) in water, so that the substrate to be treated A coating film C is formed above, and the coating film C is dried.

[0035] The film heating and dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com