Piezoelectric ceramic inductor and integrated inductor comprising piezoelectric ceramic inductor

A technology of piezoelectric ceramics and piezoelectric ceramic sheets, applied in the field of piezoelectric devices, can solve the problems of complex manufacturing process, inconvenient integration, and large volume, and achieve the effects of easy integration, no electromagnetic interference, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

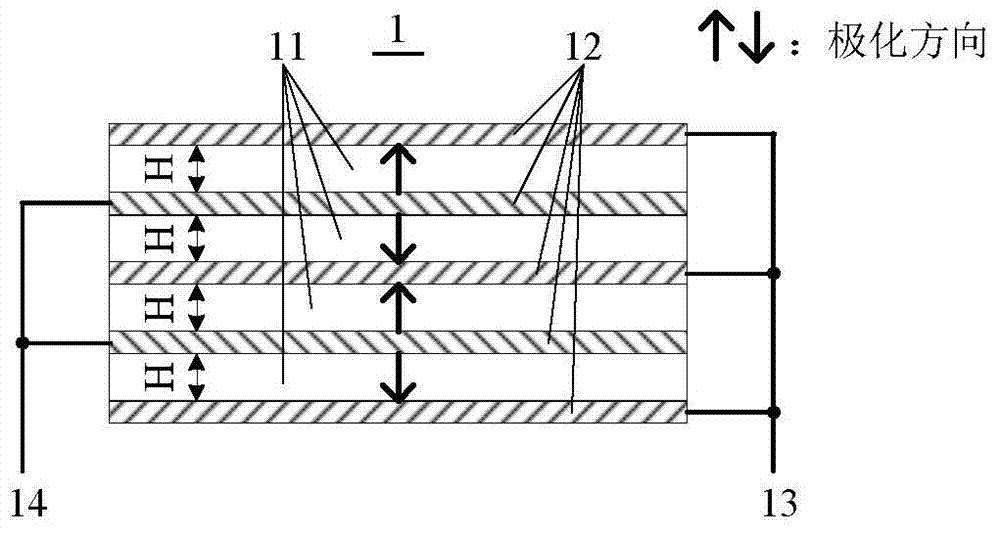

[0039] figure 1 A schematic side view showing the piezoelectric ceramic inductor of Embodiment 1, as figure 1 As shown, a piezoelectric ceramic inductor 1 of this embodiment includes four piezoelectric ceramic sheets 11 stacked with the same thickness, all of which have a thickness of H, and the thicknesses may also be different or partly the same when designed according to actual needs; The polarization directions of the two adjacent piezoelectric ceramic sheets 11 are opposite.

[0040] Electrode layers 12 are provided on the upper end surface of the topmost piezoelectric ceramic sheet 11, on the lower end surface of the bottommost piezoelectric ceramic sheet 11, and between two adjacent piezoelectric ceramic sheets 11. On each of the electrode layers 12 All have electrode leads.

[0041] The electrode lead-out lines on the odd-numbered electrode layers 12 are connected, that is, the electrode lead-out lines on the first, third, and fifth-layer electrode layers 12 are conn...

Embodiment 2

[0049] Figure 4 A schematic side view showing the piezoelectric ceramic inductor of Embodiment 2, as Figure 4 As shown, a piezoelectric ceramic inductor 2 in this embodiment includes four stacked piezoelectric ceramic sheets 21 with the same thickness, the thickness of which is H, and the thickness can also be different or partly the same when designing according to actual needs; The polarization direction of each piezoelectric ceramic sheet 21 is the same.

[0050] An upper electrode layer 22 is arranged on the upper end surface of each piezoelectric ceramic sheet 21, and a lower electrode layer 25 is arranged on the lower end surface; electrodes are arranged on each upper electrode layer 22 and the lower electrode layer 25. Lead wires; an insulating layer 26 is provided between the adjacent lower electrode layer 25 and upper electrode layer 22 .

[0051] The electrode lead-out lines on each upper electrode layer 22 are connected to form the first electrode lead-out line ...

Embodiment 3

[0055] Figure 5 shows a schematic structural view of the piezoelectric ceramic inductor of embodiment 3, as Figure 5 As shown, a piezoelectric ceramic inductor 3 in this embodiment includes two stacked piezoelectric ceramic sheets 31 with the same thickness, both of which have a thickness of H, and the thicknesses may also be different or partly the same when designed according to actual needs; The polarization directions of the two adjacent piezoelectric ceramic sheets 31 are opposite.

[0056] An electrode layer 32 is provided on the upper end surface of the first piezoelectric ceramic sheet 31, on the lower end surface of the second piezoelectric ceramic sheet 31, and between the two piezoelectric ceramic sheets 31, and each electrode layer 32 has a Equipped with electrode leads.

[0057] The electrode lead-out lines on the odd-numbered electrode layers 32 are connected, that is, the electrode lead-out lines on the first and third electrode layers 32 are connected to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com