Dual-extruding rod electric cylinder

A technology of electric cylinder and double rods, which is applied in the field of machinery, can solve the problems of difficulty in meeting work requirements, low load bearing capacity, and low transmission precision, and achieve the effects of compact structure, saving working space, and high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

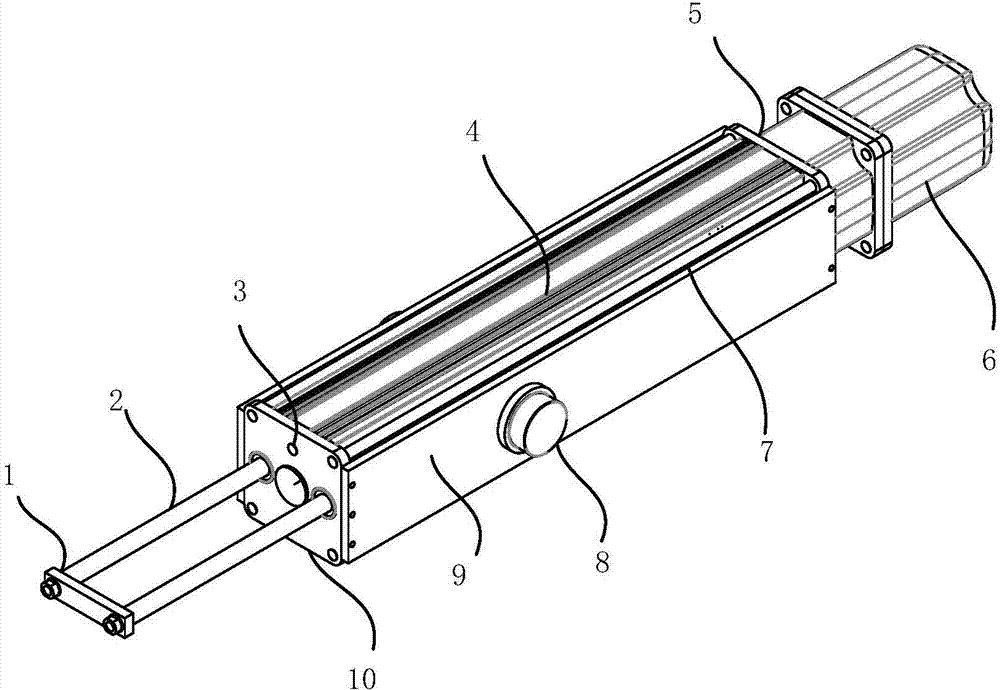

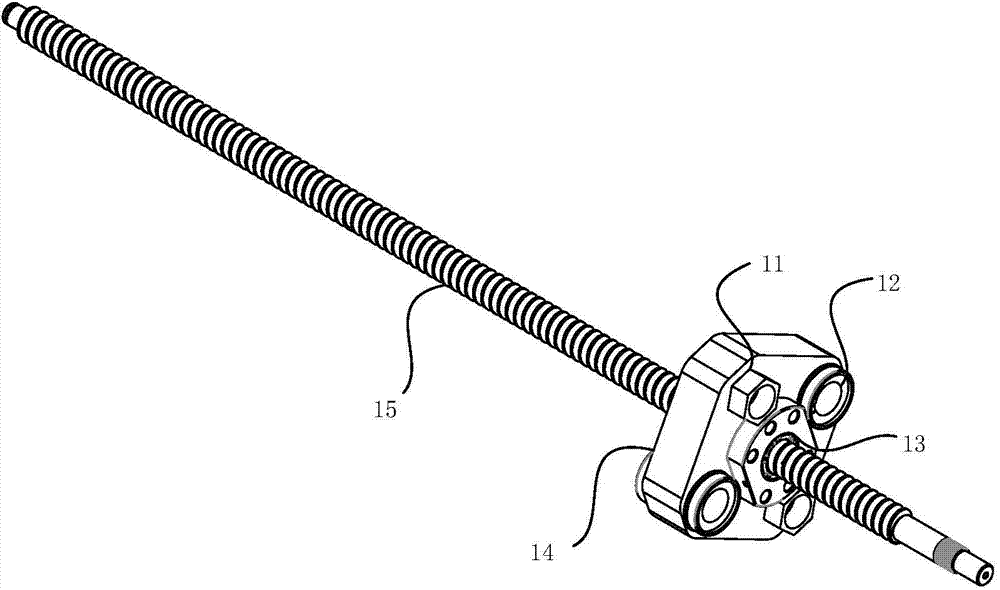

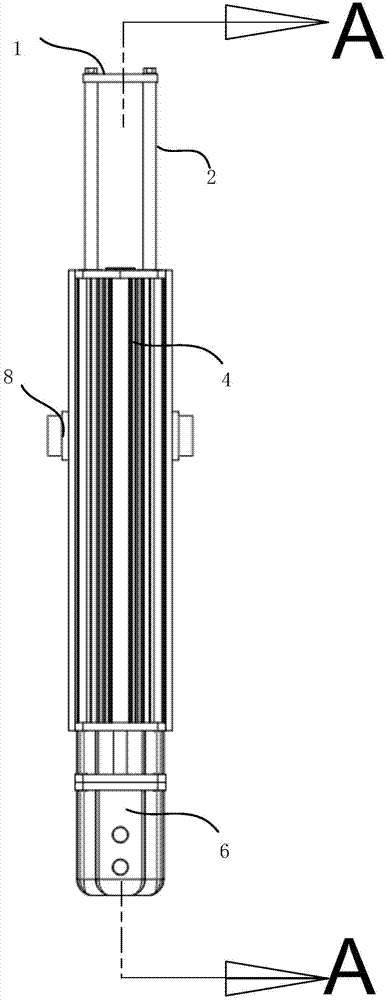

[0018] exist Figure 1 to Figure 7 In the schematic diagram of the double-rod electric cylinder shown, the front cylinder head 10 and the rear cylinder head 5 of the cylinder body 4 are connected to both ends of the cylinder body through four connecting rods 7; 9. A trunnion 8 is arranged on the trunnion connecting plate; in the cylinder body, a lead screw 15 is arranged along the central axis of the cylinder body, and one end of the lead screw passes through the nut 18 and the bearing 21 arranged in the center of the end cover 19, and through the joint The shaft device 16 is connected with the rotor of the motor 6, the above-mentioned end cover is fixed on the rear cylinder cover through a long screw rod 20, and the other end of the above-mentioned screw is sleeved in a bearing fixed on the front cylinder cover; the center of the slider 14 is provided with a nut 13 , the nut is set on the lead screw; a leading guide sleeve 17 is respectively provided at both ends of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com