Intelligent monitoring system for gravel aggregate quality

An intelligent monitoring system and aggregate technology, applied in closed-circuit television systems, measuring devices, specific gravity measurement, etc., can solve problems such as the inability to guarantee the production quality and efficiency of concrete sand and gravel aggregates, and the inability to reflect instantaneous state values in time, so as to improve The effect of accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with specific embodiments. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects.

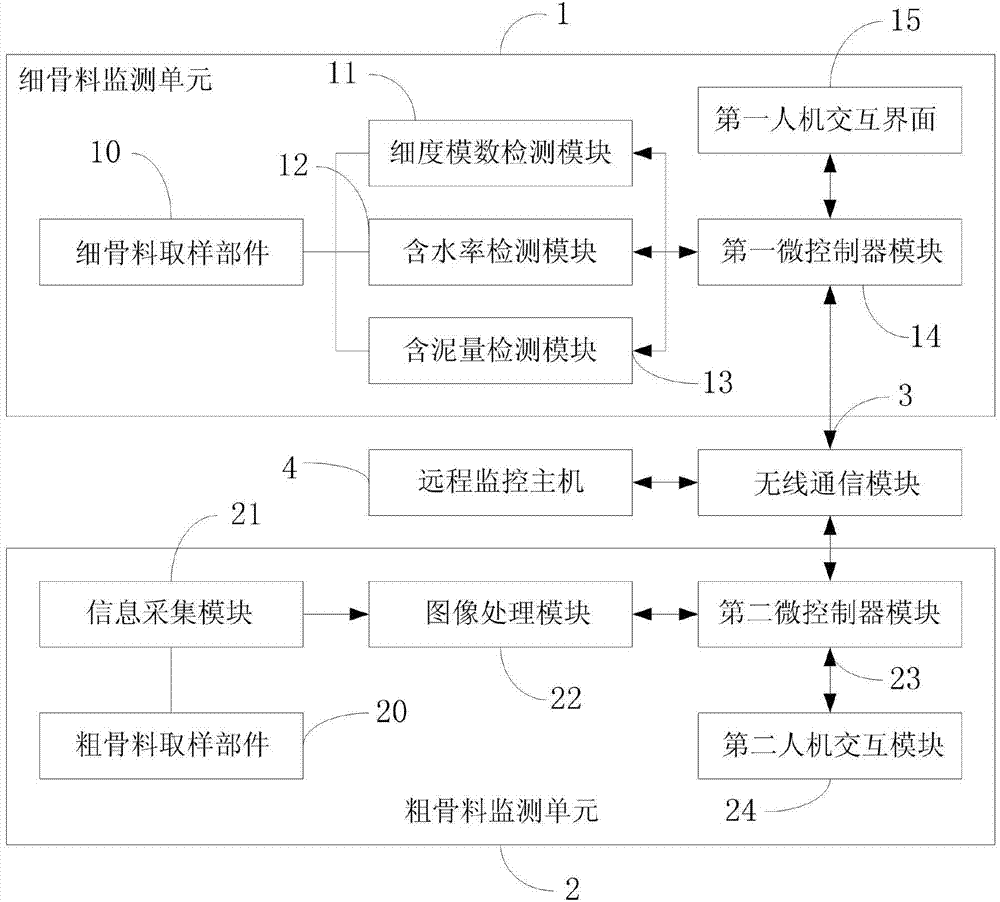

[0013] Such as figure 1 As shown, a kind of gravel aggregate quality intelligent monitoring system provided by the present invention includes a fine aggregate monitoring unit 1, a coarse aggregate monitoring unit 2, a wireless communication module 3 and a remote monitoring host 4; the fine aggregate monitoring unit 1 includes Fine aggregate sampling part 10, fineness modulus detection module 11, moisture content detection module 12, mud content detection module 13, first human-computer interaction interface 15 and first microprocessor module 14; coarse aggregate monitoring unit 2 It includes a coarse aggregate sampling component 20 , an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com