Electric device, and apparatus and method for bonding separator of electric device

A technology for an electrical device and a bonding device, which is applied in the manufacture of electrical components, non-aqueous electrolyte batteries, and electrolyte batteries, etc., can solve the problems of lowering electrical properties, scattering of heat-resistant materials of diaphragms, and thickening of diaphragm layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

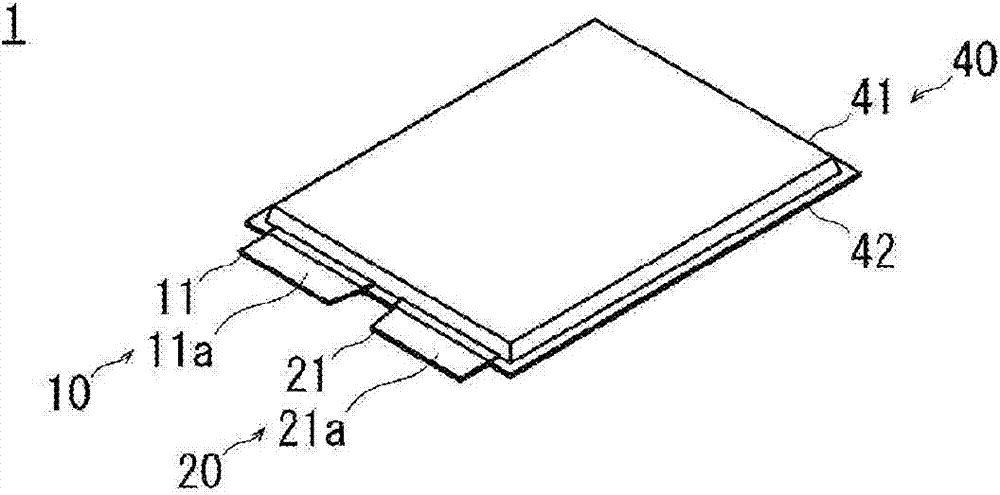

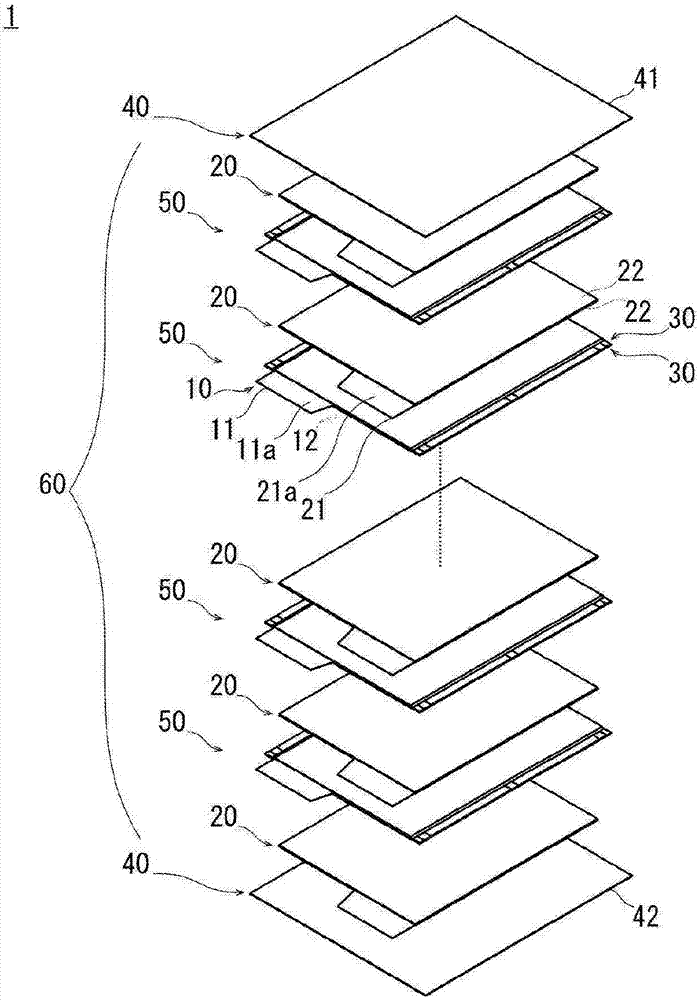

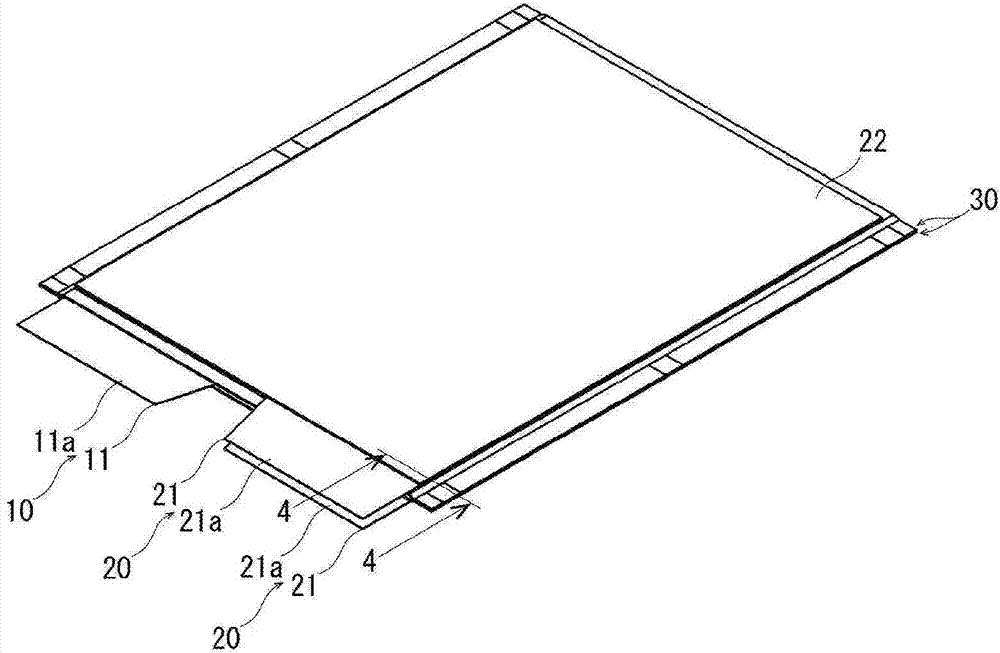

[0035] First, refer to Figure 1 ~ Figure 4 The structure of the electrical device 1 in which the diaphragms 30 are joined to each other using the diaphragm joining apparatus 100 of the first embodiment will be described.

[0036] figure 1 It is a perspective view showing the electrical device 1 to which the diaphragm 30 is joined by the diaphragm joining apparatus 100 . figure 2 It is an exploded perspective view showing the electrical device 1 to which the diaphragm 30 is joined by the diaphragm joining apparatus 100 . image 3 It is a perspective view showing a state in which the negative electrode 20 is stacked on both ends of the packaged electrode 50 formed by packaging the positive electrode 10 with a pair of separators 30 using the separator bonding apparatus 100 . Figure 4 Yes image 3 Sectional view at line 4-4 shown.

[0037] like figure 1 As shown, the electric device 1 corresponds to, for example, a lithium-ion secondary battery, a polymer lithium battery...

no. 2 Embodiment approach

[0085] refer to Figure 11 The electrical device of the second embodiment will be described.

[0086] In the second embodiment, the same reference numerals are used for members having the same configurations as those in the first embodiment, and the above descriptions are omitted.

[0087] Figure 11 It is a cross-sectional view showing a part of the electrical device in a state where the positive electrodes 10 are stacked on both ends of a packed electrode 70 formed by packing the negative electrode 20 with a pair of separators 30 .

[0088] The heat-resistant material 32 of the separator 30 abuts against the negative electrode active material 22 of the negative electrode 20 to generate frictional force. Therefore, even if the electrical device vibrates or receives an impact, it is possible to suppress movement of the negative electrode 20 inside the packed electrode 50 in which the negative electrode 20 is packed with the separator 30 . That is, by suppressing the laminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com