Soot Drying Buffer Filter Bottle

A soot and drying technology, which is used in the preparation of test samples, combined devices, and separation of dispersed particles, etc., can solve the problems of volume limitation, high cost, frequent water discharge, etc., to reduce the cost of parts and labor, and reduce the cost of consumables. The effect of using and increasing the condensation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

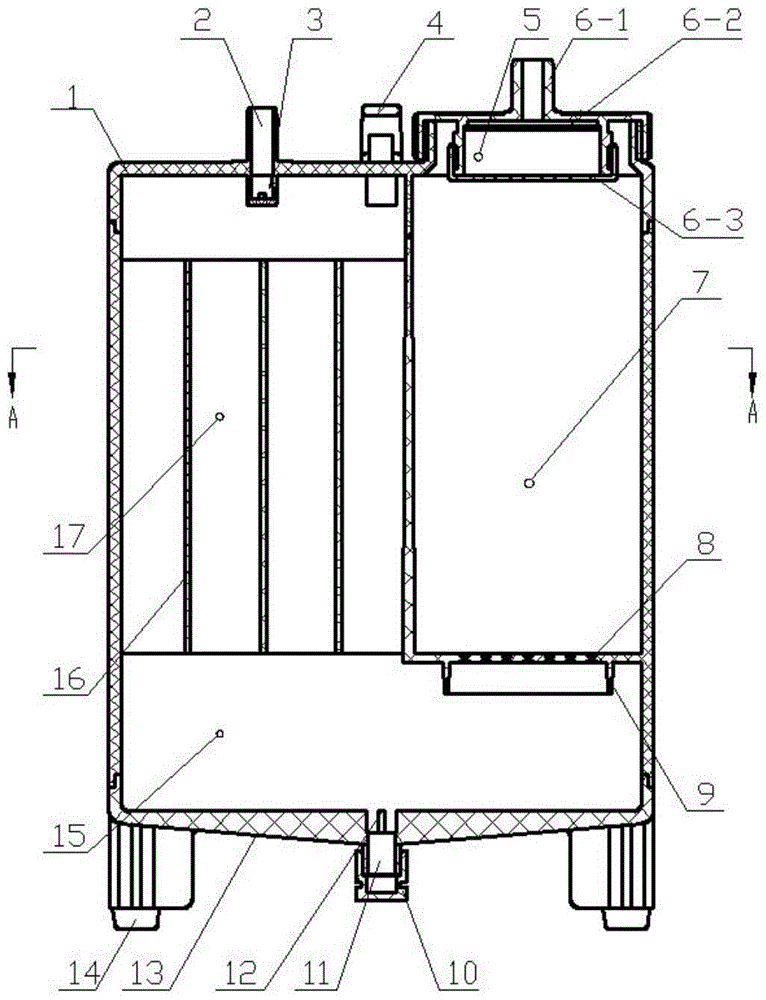

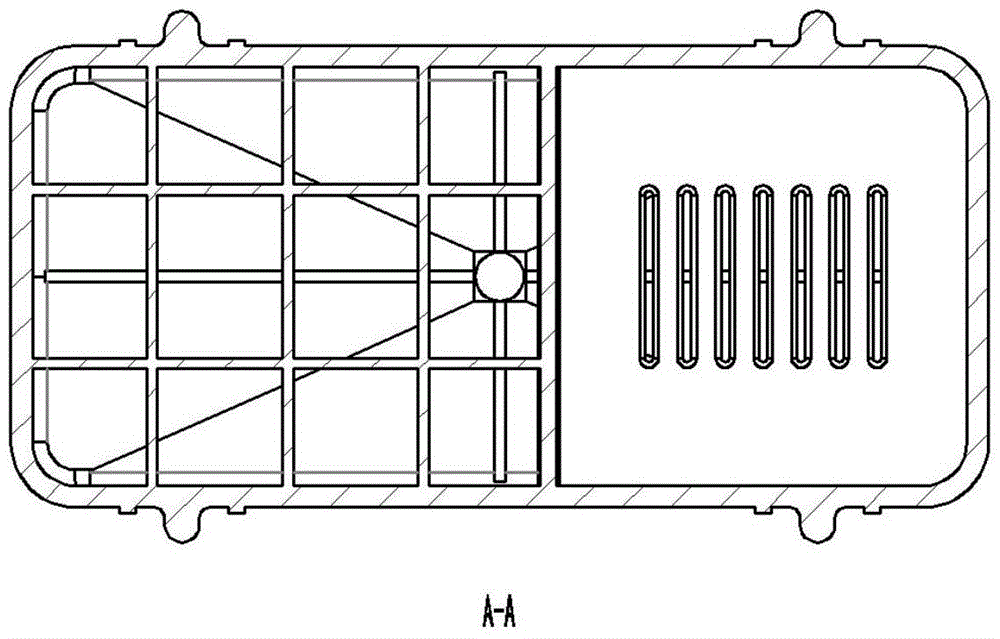

[0030] Such as figure 1 , 2 , shown in 3 and 4, a kind of smoke and dust drying buffer filter bottle comprises smoke and dust sampling device, water vapor condensation device, condensed water treatment system, drying device and air outlet system, and described water vapor condensation device comprises loam cake 1, condensation cavity 17 and condensation The chamber partition 16, the condensation chamber partition 16 divides the condensation chamber 17 into a plurality of air chamber passages along the airflow direction.

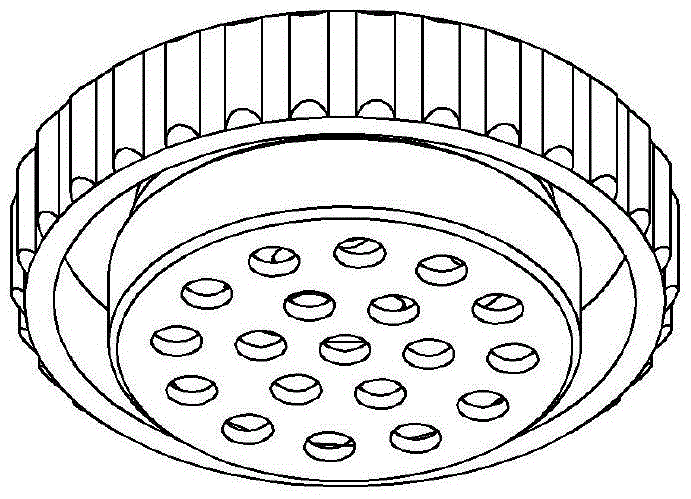

[0031] The soot sampling device is installed on the upper cover 1 of the water vapor condensing device, and includes a smoke nozzle 2 and a condensation cavity nozzle 3 connected in sequence. The surface of the air nozzle 3 is covered with small holes of 2-4mm.

[0032] The condensed water treatment system includes a water storage chamber 15, a bottom cover 13 and a water discharge hole 11, and also includes a condensed water deflector 12 installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com