Magnetic circuit structure of double-row permanent magnet centripetal excitation rectangular open magnetic field type electromagnetic vibrating table with magnetic field tracking compensation

A tracking compensation, electromagnetic vibration technology, applied in vibration testing, testing of fluids using vibration, machine/structural components, etc., can solve the problems of magnetization effect limitation, difficult to guarantee magnetic field uniformity, magnetic circuit influence, etc. The effect of machining and assembly accuracy, simple and reliable magnetic circuit structure, and large air-gap magnetic induction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in detail below with reference to the accompanying drawings, and examples will be given.

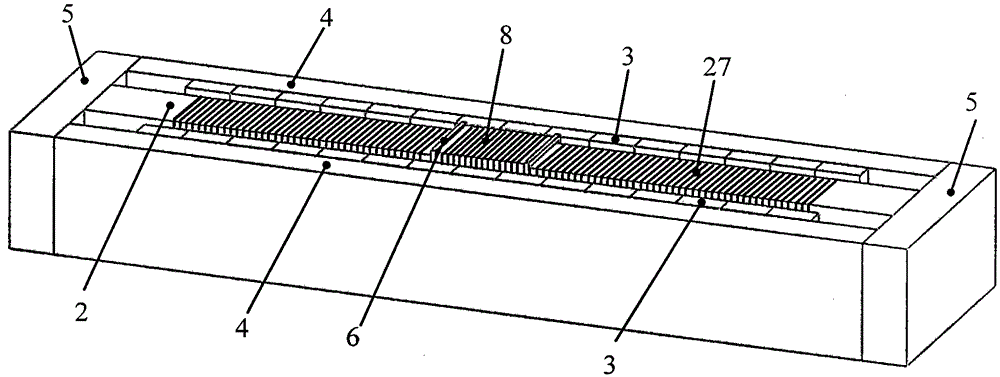

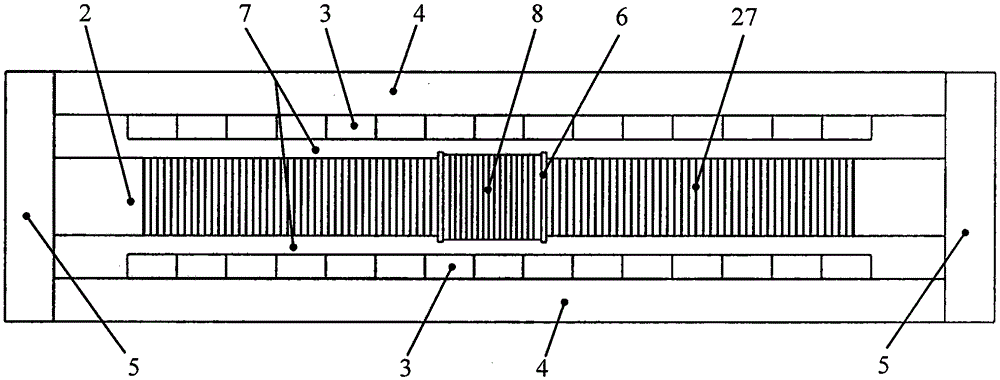

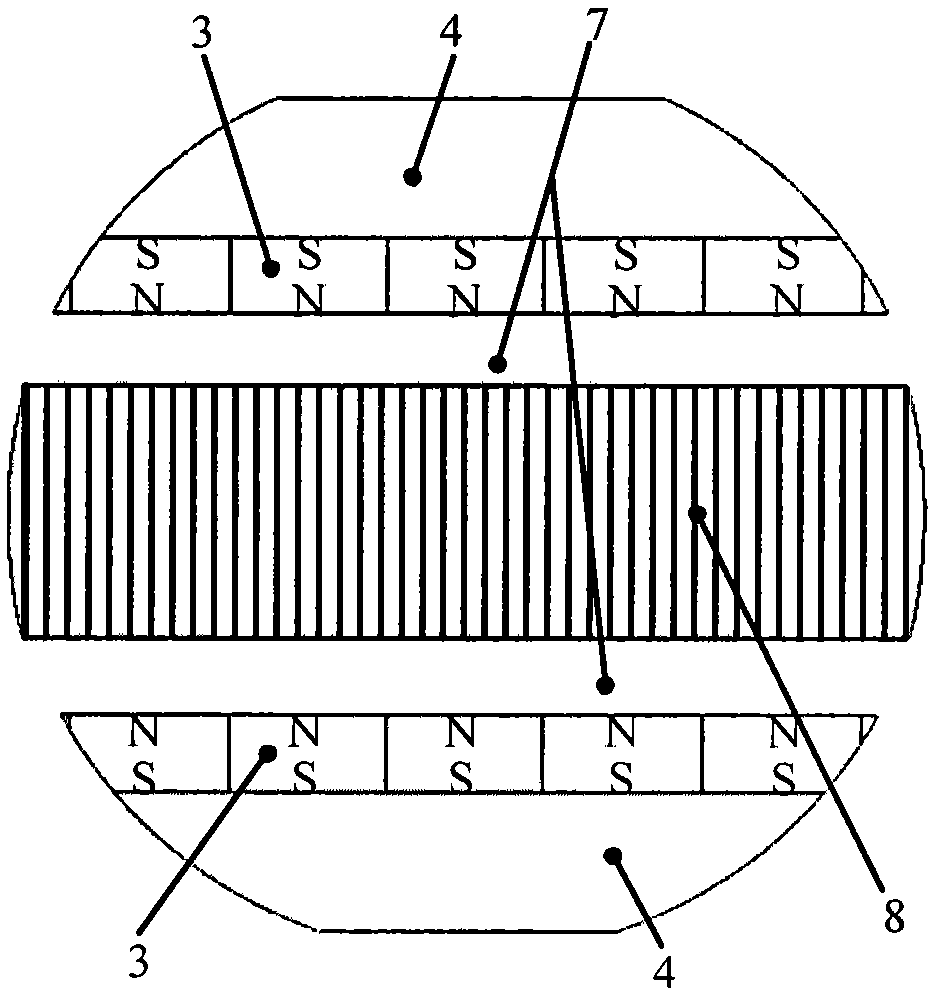

[0032] A magnetic circuit structure of a double-row permanent magnet centripetal excitation rectangular open magnetic field type electromagnetic vibrating table with magnetic field tracking compensation, consisting of a central yoke 2, a permanent magnet 3, an outer yoke 4, an end yoke 5, a coil bobbin 6 and a working coil 8, the overall structure is axisymmetric. The cross-sections of the central yoke 2, permanent magnet 3, outer yoke 4, and end yoke 5 are all rectangular. The cross-section of the coil bobbin 6 is square-shaped. The ends are respectively rigidly connected with the two end yokes 5 to form a zigzag yoke structure. The central yoke 2 is installed on the long axis of the zigzag yoke structure, and the two ends are respectively rigidly connected with the two end yokes 5. The permanent magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com