Preparation method of wide interlayer spacing and easily-striping graphite oxide

A technology of layer spacing and easy peeling, which is applied in the preparation of easy peeling graphite oxide and the field of wide layer spacing, can solve the problems of unsatisfactory peeling effect, hidden dangers, unfavorable production and preparation, etc., so as to shorten the time required for peeling and avoid excessive peeling. Destructive, beneficial effects on mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

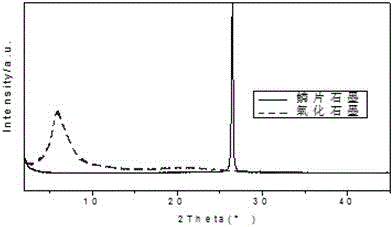

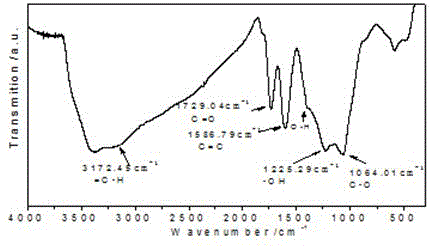

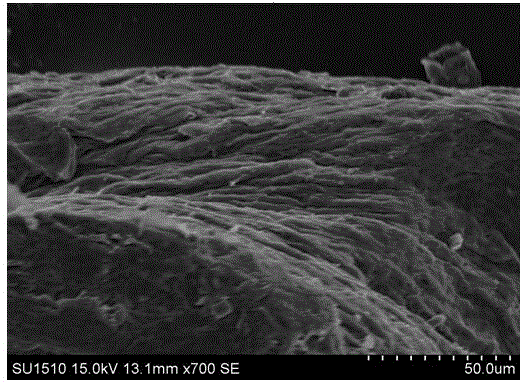

[0013] The preparation method of wide interlayer spacing of the present invention, easy-to-exfoliate graphite oxide is as follows: under ice-water bath condition, particle size is that 40 um flake graphite 1g is poured in the concentrated sulfuric acid 60ml of cooling 98% and the concentrated phosphoric acid 7ml mixed acid of 85%, mechanical After stirring for 30 minutes, slowly and evenly add 8 g of permanganate, and the permanganate is slowly added within 2 hours, and the temperature in the whole process is controlled at 0-10 °C. After the addition of permanganate was completed, the ice bath was removed to let the system warm up slowly for 1 hour, and then the temperature of the reaction system was raised with a water bath until the final temperature rose to 50 °C, and the reaction was carried out at medium temperature and constant temperature for 20 hours. After the reaction is over, use an ice-water bath to cool down the system, then add 100ml of deionized water dropwise fo...

Embodiment 2

[0016] A kind of preparation method of wide interlayer distance, easily exfoliated graphite oxide comprises the following process: under the condition of ice-water bath, 1g of flake graphite with a particle size of 10um is poured into 45ml of cooled concentrated sulfuric acid of 98% and 5ml of concentrated phosphoric acid of 85% mixed acid , after mechanical stirring for 30 minutes, slowly and evenly add 6g of permanganate, the permanganate is added slowly within 2 hours, and the temperature in the whole process is controlled at 0~10℃. After the permanganate was added, the ice bath was removed to allow the system to slowly heat up and react for 1 hour, then the temperature of the reaction system was raised in a water bath until the final temperature was raised to 50°C, and the reaction was carried out with medium temperature and constant temperature stirring for 15 hours. After the reaction is over, use an ice-water bath to cool down the system, and then add 80ml of deionized w...

Embodiment 3

[0018] A kind of preparation method of wide interlayer spacing, easy exfoliation graphite oxide, comprises the following process: under ice water bath condition, particle size is that 200 um flake graphite 1g is poured into 90ml of the concentrated sulfuric acid of 98% that cools well and 10ml of the concentrated phosphoric acid of 85% mixed acid In the process, after mechanical stirring for 30 minutes, slowly and evenly add 10 g of permanganate, and the permanganate is slowly added within 2 hours, and the temperature in the whole process is controlled at 0-10 °C. After the addition of permanganate, remove the ice bath and allow the system to naturally heat up slowly for a period of time (1~2 h), then heat up the reaction system with a water bath until the final temperature rises to 50°C, and carry out medium temperature and constant temperature stirring reaction for 20 h. After the reaction is over, use an ice-water bath to cool down the system, and then add 100ml of deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com