A kind of preparation method of acid-resistant and freeze-resistant fly ash glazed tile

A technology of fly ash and glazed tiles, which is applied in the field of glazed tile manufacturing, can solve problems such as human body and biological hazards, dust generation, air pollution, etc., and achieve the effects of improving acid resistance and frost resistance, improving compressive strength, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

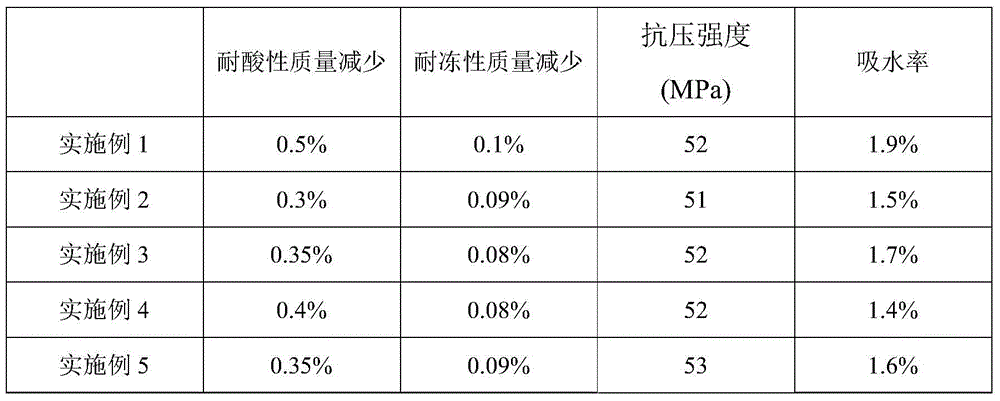

Examples

Embodiment 1

[0029] A preparation method of acid-resistant and freeze-resistant fly ash glazed tile,

[0030] (1) Raw material preparation: take the following raw materials in proportion by weight:

[0031] 70 parts of fly ash; 15 parts of clay; 5 parts of barium carbonate; 5 parts of limestone; 1 part of sodium tripolyphosphate; 1 part of cellulose;

[0032] (2) Mixing: mix each raw material in a grinder, the grinding balls are alumina grinding balls, and the grinding time is 1 hour;

[0033] (3) Glaze the sieved compact: after mixing the materials, pass through a 100-mesh sieve, then put them into a mold, cold isostatically press for 30 minutes under a pressure of 30MPa, dry and apply glaze;

[0034] (4) Primary sintering: place the glazed green body in a sintering kiln for sintering, the heating rate is 50°C / min, the sintering temperature is 900°C, and the sintering time is 2 hours. Cool with the furnace to obtain a sintered semi-finished product;

[0035] (5) Primary strengthening: i...

Embodiment 2

[0041] A preparation method of acid-resistant and freeze-resistant fly ash glazed tile,

[0042] (1) Raw material preparation: take the following raw materials in proportion by weight:

[0043] 65 parts of fly ash; 17 parts of clay; 4 parts of barium carbonate; 4 parts of limestone; 2 parts of sodium tripolyphosphate; 2 parts of cellulose;

[0044] (2) Mixing: mix each raw material in a grinder, the grinding balls are alumina grinding balls, and the grinding time is 1 hour;

[0045] (3) Glaze the sieved compact: after mixing the materials, pass through a 100-mesh sieve, then put them into a mold, cold isostatically press for 30 minutes under a pressure of 30MPa, dry and apply glaze;

[0046] (4) Primary sintering: place the glazed green body in a sintering kiln for sintering, the heating rate is 50°C / min, the sintering temperature is 900°C, and the sintering time is 2 hours. Cool with the furnace to obtain a sintered semi-finished product;

[0047] (5) Primary strengthening:...

Embodiment 3

[0053] A preparation method of acid-resistant and freeze-resistant fly ash glazed tile,

[0054] (1) Raw material preparation: take the following raw materials in proportion by weight:

[0055] 60 parts of fly ash; 20 parts of clay; 4 parts of barium carbonate; 4 parts of limestone; 2 parts of sodium tripolyphosphate; 2 parts of cellulose;

[0056] (2) Mixing: mix each raw material in a grinder, the grinding balls are alumina grinding balls, and the grinding time is 1 hour;

[0057] (3) Glaze the sieved compact: after mixing the materials, pass through a 100-mesh sieve, then put them into a mold, cold isostatically press for 30 minutes under a pressure of 30MPa, dry and apply glaze;

[0058] (4) Primary sintering: place the glazed green body in a sintering kiln for sintering, the heating rate is 50°C / min, the sintering temperature is 900°C, and the sintering time is 2 hours. Cool with the furnace to obtain a sintered semi-finished product;

[0059] (5) Primary strengthening:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com