Adhesive tape

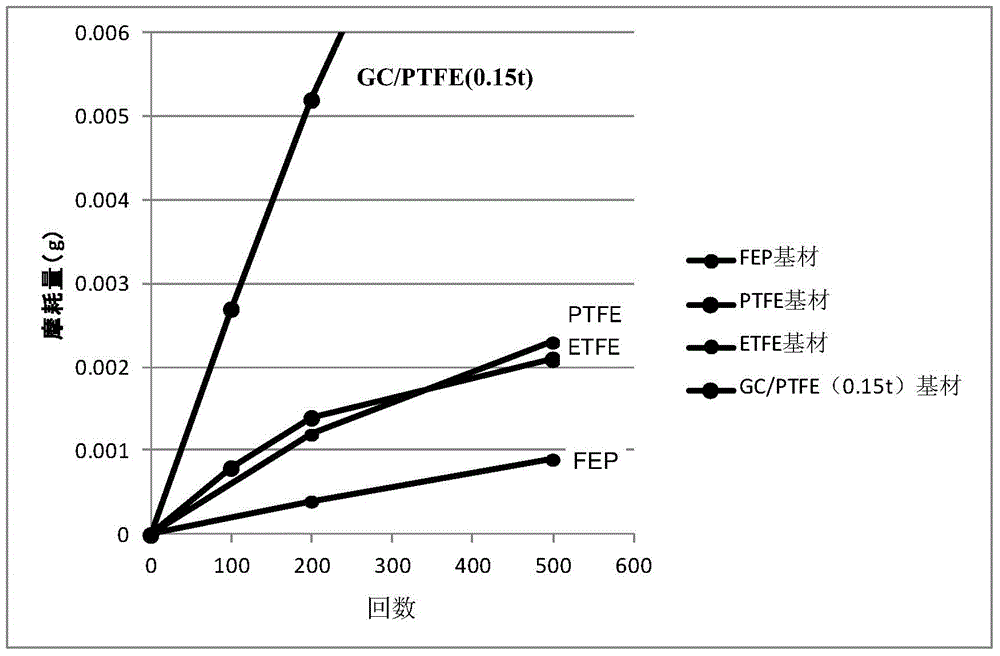

A technology of adhesive tape and gel rate, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc., can solve the problems of weakened surface release effect, irregular mold surface, and floating of the bonding surface, etc. , to achieve the effect of increasing gel rate and molecular weight, improving work efficiency, and improving anti-reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

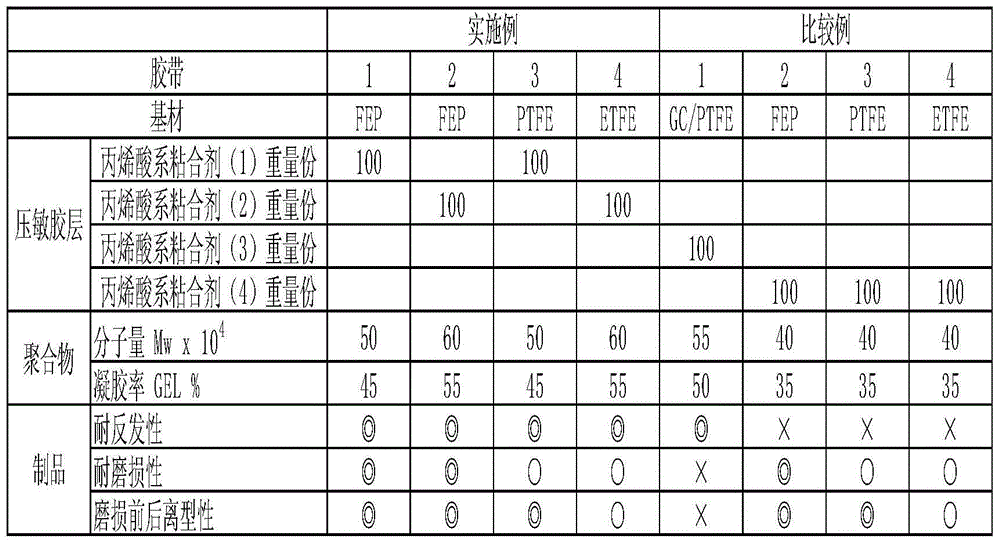

Embodiment 1

[0056] 30 parts by weight of acrylic acid, 2.5 parts by weight of AIBN, 55 parts by weight of vinyl acetate, and 900 parts by weight of butyl acrylate were mixed, and nitrogen substitution was performed for 2 hours. Superposition was performed at 60° C. for 6 hours under nitrogen substitution to obtain an acrylic polymer (1) having a weight average molecular weight of 500,000 and a gel fraction of 45%.

[0057] Acrylic adhesive (1) was obtained by uniformly blending 100 parts by weight of acrylic polymer (1) and 2 parts by weight of isocyanate compound containing a trifunctional group (trade name "CORONATEL", manufactured by Nippon Polyurethane Co., Ltd.).

[0058] The above-mentioned acrylic adhesive (1) was coated on a fluorinated ethylene-propylene polymer FEP (thickness: 75 μm) as a substrate so that the thickness after drying was 30 μm, and the adhesive tape (1) was obtained after drying.

Embodiment 2

[0060] 40 parts by weight of acrylic acid, 3.0 parts by weight of AIBN, 55 parts by weight of vinyl acetate, and 900 parts by weight of butyl acrylate were mixed, and nitrogen substitution was performed for 2 hours. Superposition was performed at 60° C. for 6 hours under nitrogen substitution to obtain an acrylic polymer (2) having a weight average molecular weight of 600,000 and a gel fraction of 55%.

[0061] Acrylic adhesive (2) was obtained by uniformly blending 100 parts by weight of acrylic polymer (2) and 2 parts by weight of isocyanate compound containing trifunctional groups (trade name "CORONATEL", manufactured by Nippon Polyurethane Co., Ltd.).

[0062] The above-mentioned acrylic adhesive (2) was coated on a fluorinated ethylene-propylene polymer FEP (thickness: 75 μm) as a substrate so that the thickness after drying was 30 μm, and the adhesive tape (2) was obtained after drying.

Embodiment 3

[0064] The procedure of Example 1 was repeated except that the above-mentioned acrylic adhesive (1) of Example 1 was coated on polytetrafluoroethylene PTFE (thickness: 75 μm) as a base material so that the thickness after drying was 30 μm. Adhesive tape (3) was obtained after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com