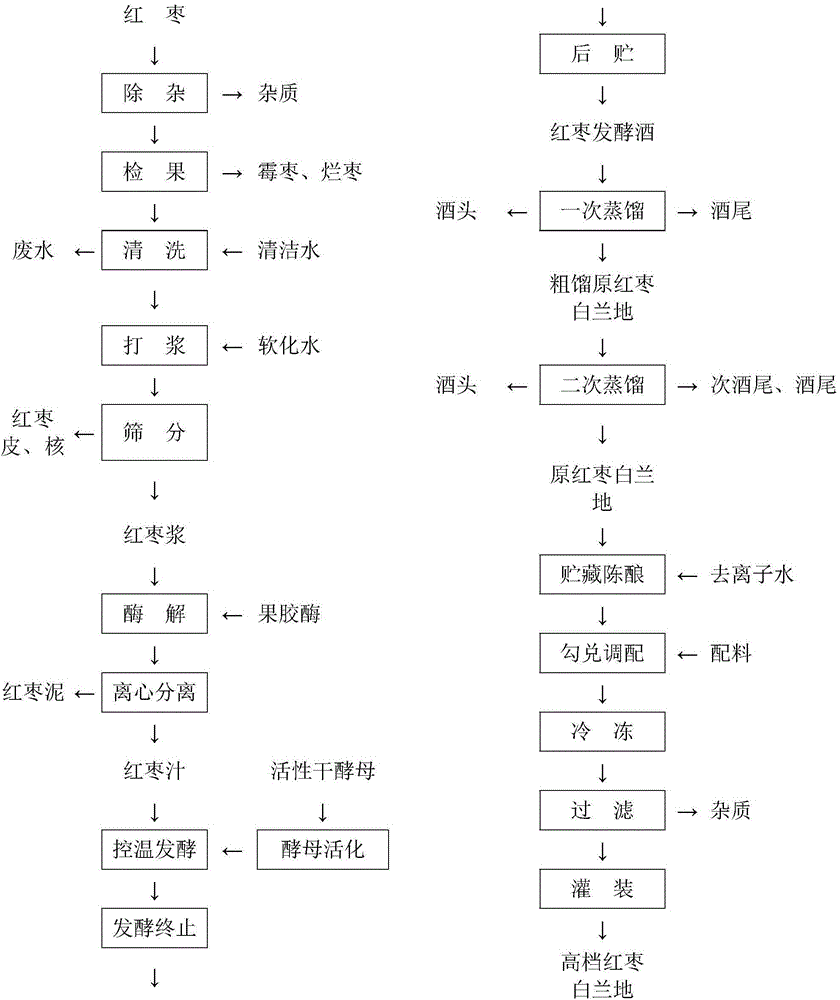

Process for producing high-grade red jujube brandy

A production process, brandy technology, applied in the field of fermentation process for producing high-grade jujube brandy, can solve problems such as inability to produce high-grade jujube brandy products, and achieve the effects of safe and reliable production operation, improved filtering conditions, and opportunities to avoid bad odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] Embodiment 1: (with Shandong Jinsixiaozao as raw material)

[0119] (1) selection fruit

[0120] Purchasing completely natural ripe jujube fruits, the fruit is required to be plump, dark red, and have the unique aroma of jujube;

[0121] (2) Impurity removal, fruit inspection, cleaning

[0122] The impurities in the jujube fruit are removed mechanically, and the fruits with insect eyes, rotten or moldy are removed through manual selection. Remove the soil on the surface of the fruit with clean water, and finally spray and clean with demineralized water and drain;

[0123] (3) beating

[0124] Mix the cleaned raw jujube with 40°C demineralized water according to the ratio of 1:4 (the weight ratio of jujube and demineralized water) and beat to make jujube pulp, and keep the jujube core intact;

[0125] (4) Screening

[0126] The jujube skin and jujube pit in the jujube pulp are separated by a planar vibrating sieve;

[0127] (5) Enzymolysis

[0128] Add 0.1% pectin...

Embodiment 2

[0155] Embodiment 2: (with Shanxi Junzao as raw material)

[0156] (1) selection fruit

[0157] Purchasing completely natural ripe jujube fruits, the fruit is required to be plump, dark red, and have the unique aroma of jujube;

[0158] (2) Impurity removal, fruit inspection, cleaning

[0159] The impurities in the jujube fruit are removed mechanically, and the fruits with insect eyes, rotten or moldy are removed through manual selection. Remove the soil on the surface of the fruit with clean water, and finally spray and clean with demineralized water and drain;

[0160] (3) beating

[0161] Mix the cleaned raw jujube with 35°C demineralized water according to the ratio of 1:5 (the weight ratio of jujube and demineralized water) and beat to make jujube pulp, and keep the jujube core intact;

[0162] (4) Screening

[0163] The jujube skin and jujube pit in the jujube pulp are separated by a planar vibrating sieve;

[0164] (5) enzymatic hydrolysis,

[0165] Add 0.15% pec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com