00Cr13Mo corrosion-resistant ferrite stainless steel

A ferrite and stainless steel technology, applied in the field of heat exchange tubes, 00Cr13Mo corrosion-resistant ferritic stainless steel, can solve the problems of increased equipment cost, and achieve the effect of improved pitting corrosion resistance, low cost, and increased pitting corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

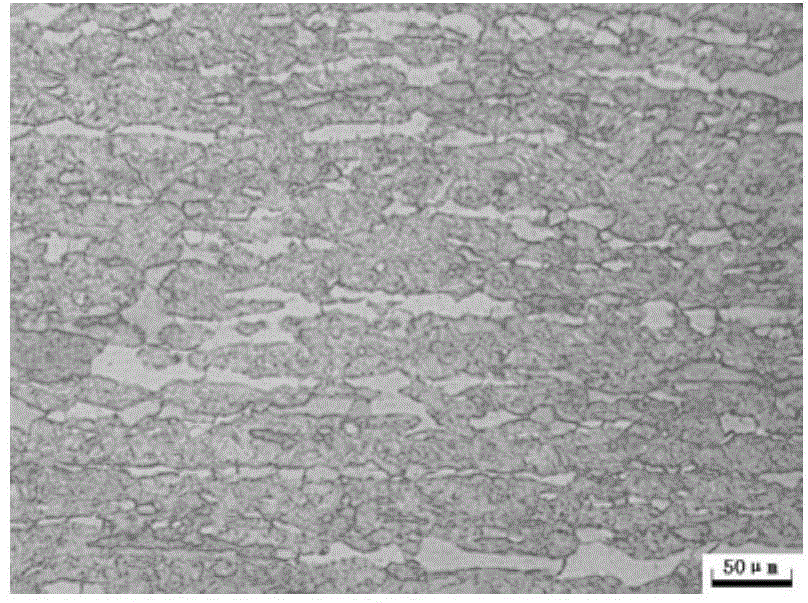

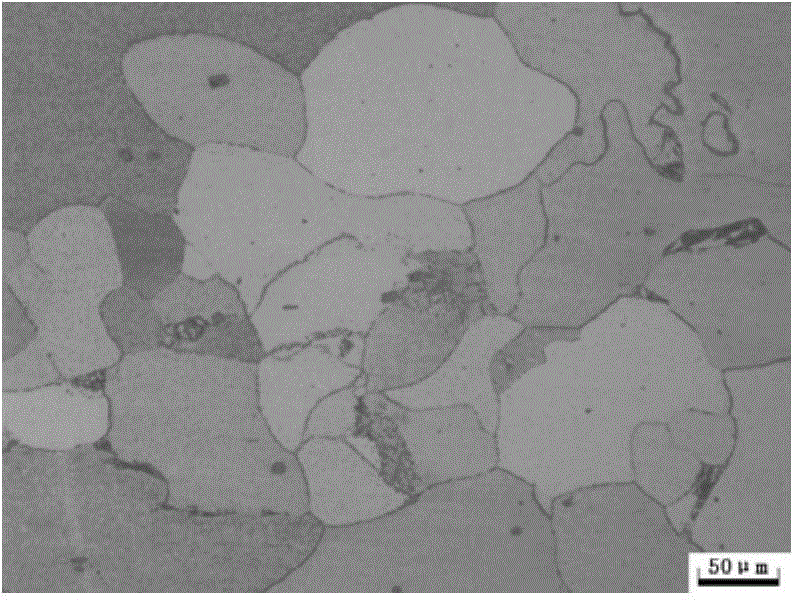

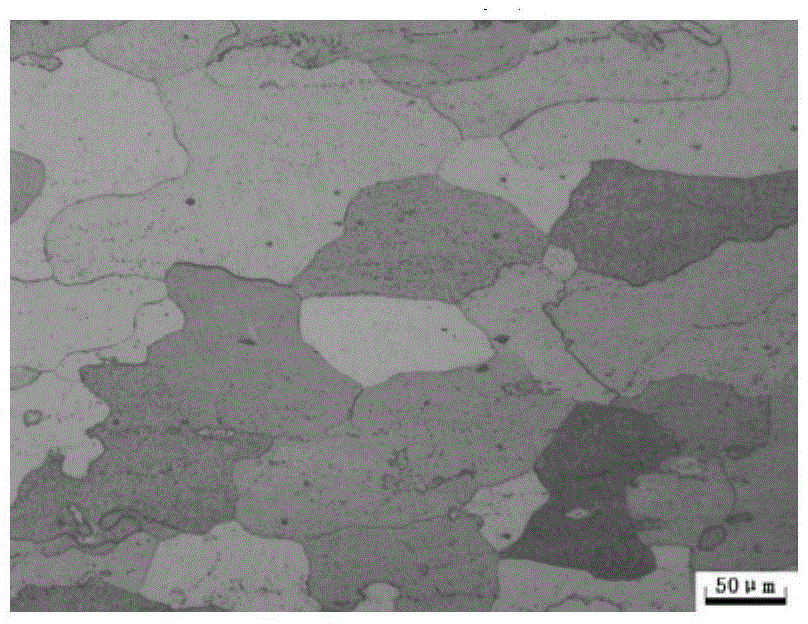

[0023] The test material is selected on the basis of the chemical composition standard of 0Cr13 ferritic stainless steel, and 0.20-0.50% Mo is added to optimize the content of C, Cr, Ni, N and other elements. The chemical composition used is shown in Table 2. The experimental material except Mo Other ingredients are the same as the prior art. In the above list, serial numbers 3# to 6# are embodiments of the present invention, and serial numbers 1# and 2# are steel grades in the prior art. Serial number 1# is the common chemical composition of 0Cr13 stainless steel produced in industry, and serial number 2# has higher Cr content and lower C content, which is a chemical composition with higher corrosion resistance. The room-temperature mechanical performance comparison table of the embodiment and the prior art is shown in Table 3. It can be seen that embrittlement phenomenon has occurred in serial number 2#, therefore, C should not be too low and Cr should not be too high; Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com