Crystal phase regulator and microcrystalline glass using same

A technology of glass-ceramics and modifiers, which is applied in the field of glass processing, can solve the problems of low glass yield, increase the cost of glass research and development, and the difficulty of processing technology, and achieve good thermal vibration stability, low thermal expansion coefficient, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

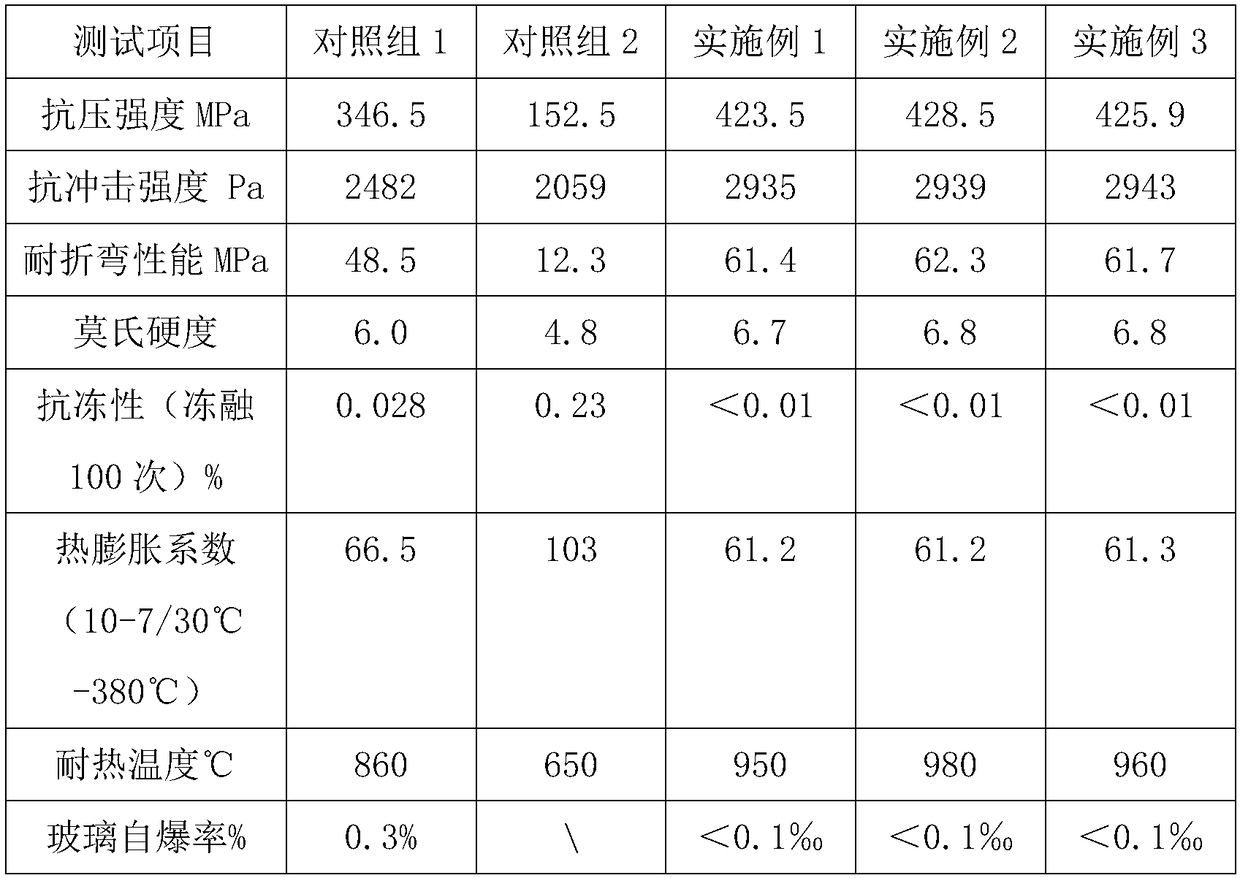

Examples

Embodiment 1

[0040] A glass-ceramic, according to mass percentage, its raw material components include: 16% magnesium oxide, 15% aluminum oxide, 0.5% titanium dioxide, 1.3% boron oxide, 12% crystal phase regulator, and the balance is silicon dioxide and non Avoid impurities.

[0041] The preparation method of this type of glass-ceramics is as follows:

[0042] (1) According to the mass percentage, the raw material components are mixed and ball-milled evenly, the mixture is added to the glass furnace, and the glass melt is obtained by firing at a temperature of 1550 ° C in the heating section;

[0043] (2) The glass melt passes through the clarification section, the cooling section, the stirring section and the homogenization section in turn in the platinum channel, and realizes the clarification and homogenization treatment with the help of the electric heating flange, the ventilation pipe and the stirring rod. After the homogenization treatment The molten glass enters into the feeding bi...

Embodiment 2

[0050] A glass-ceramic, according to mass percentage, its raw material components include: 20% magnesium oxide, 19% aluminum oxide, 0.8% titanium dioxide, 2.2% boron oxide, 14.5% crystal phase regulator, and the balance is silicon dioxide and non Avoid impurities.

[0051] The preparation method of this type of glass-ceramics is as follows:

[0052] (1) According to the mass percentage, the raw material components are mixed and ball-milled evenly, the mixture is added to the glass furnace, and the glass melt is obtained by firing at a temperature of 1600 ° C in the heating section;

[0053] (2) The glass melt passes through the clarification section, the cooling section, the stirring section and the homogenization section in turn in the platinum channel, and realizes the clarification and homogenization treatment with the help of the electric heating flange, the ventilation pipe and the stirring rod. After the homogenization treatment The molten glass enters into the feeding ...

Embodiment 3

[0060] A glass-ceramic, according to the mass percentage, its raw material components include: 18% magnesium oxide, 17% aluminum oxide, 0.6% titanium dioxide, 1.8% boron oxide, 14% crystal phase modifier, and the balance is silicon dioxide and non Avoid impurities.

[0061] The preparation method of this type of glass-ceramics is as follows:

[0062] (1) According to the mass percentage, the raw material components are mixed and ball-milled evenly, the mixture is added into the glass kiln, and fired at a temperature of 1580 ° C in the heating section to obtain a glass melt;

[0063] (2) The glass melt passes through the clarification section, the cooling section, the stirring section and the homogenization section in turn in the platinum channel, and realizes the clarification and homogenization treatment with the help of the electric heating flange, the ventilation pipe and the stirring rod. After the homogenization treatment The molten glass enters into the feeding bin;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com