Anti-collision and anti-rollover flexible roller intelligent protective fence

An anti-rollover and anti-collision technology, which is applied to roads, road safety devices, roads, etc., can solve the problems of vehicle rollover, missed inspection, and inability to release energy, and achieve the effect of reducing the degree of damage and the degree of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

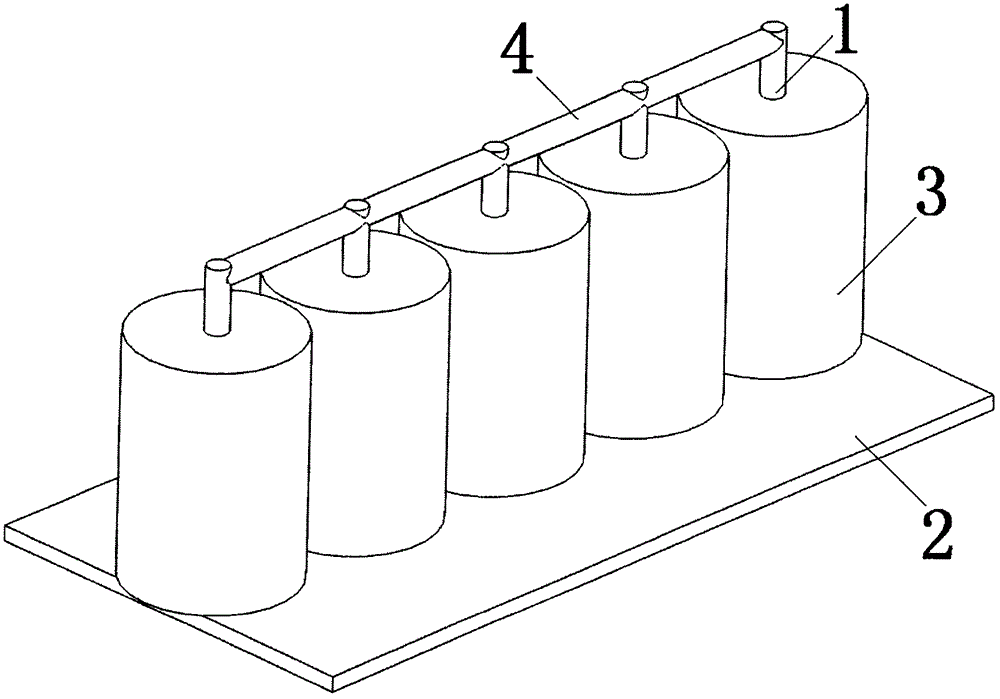

[0026] Such as figure 1 As shown, 1 is a main shaft, 2 is a foundation, 3 is a flexible roller, and 4 is an upper connection belt.

[0027] During construction, the multiple main shafts 1 are pre-embedded in the foundation 2, the inner hole of the flexible roller 3 is sleeved on the main shaft 1, and the upper connecting belt 4 fixes the upper ends of the multiple main shafts 1 to increase the overall strength.

[0028] The height of flexible drum 3 can be designed according to the wheel height of truck and bus.

[0029] The way of fixing the upper connection belt 4 and the main shaft 1 can be integral molding, bolt connection, bolt connection, welding, riveting and the like.

[0030] A gap is designed between the plurality of flexible rollers 3 so that their independent rotation is not interfered with.

Embodiment 2

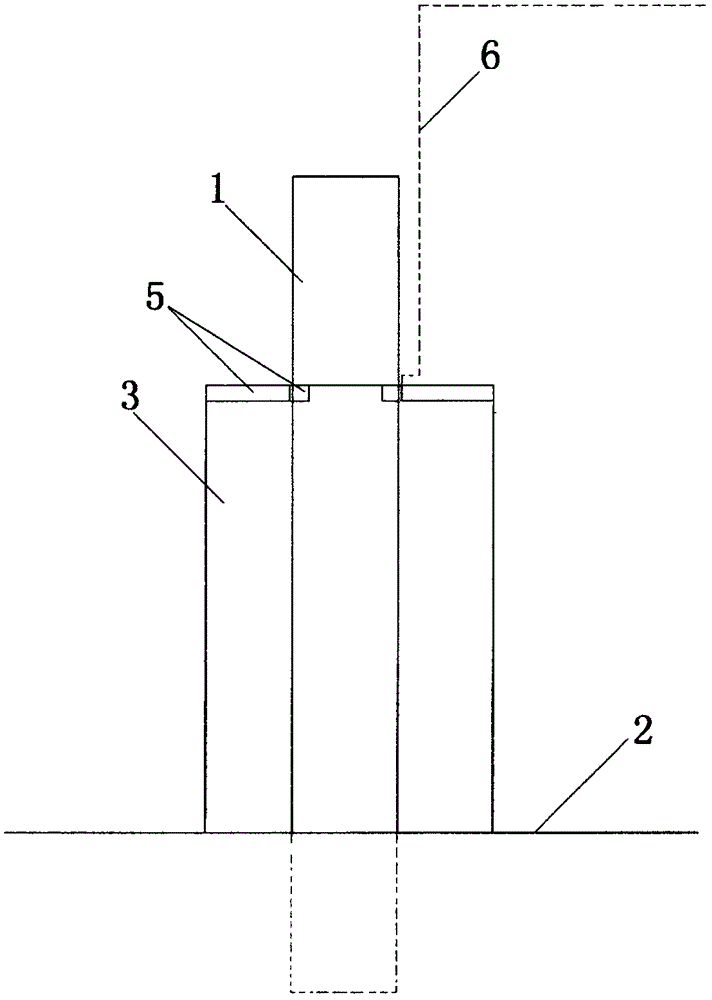

[0032] Such as figure 2 As shown: In order to achieve the purpose of actively detecting accidents, an angular displacement sensor 5 is arranged between the flexible roller 3 and the main shaft 1. The outer ring of the angular displacement sensor 5 contacts the flexible roller 3, and the inner ring contacts the flexible roller 3. Once the flexible roller If there is an angular deviation between 3 and the main shaft 1, the signal line 6 will transmit the signal to the traffic control department.

[0033] The power supply of angular displacement sensor 5 adopts solar cell.

[0034] The angular displacement sensor 5 can also be replaced by a Hall position sensor.

Embodiment 3

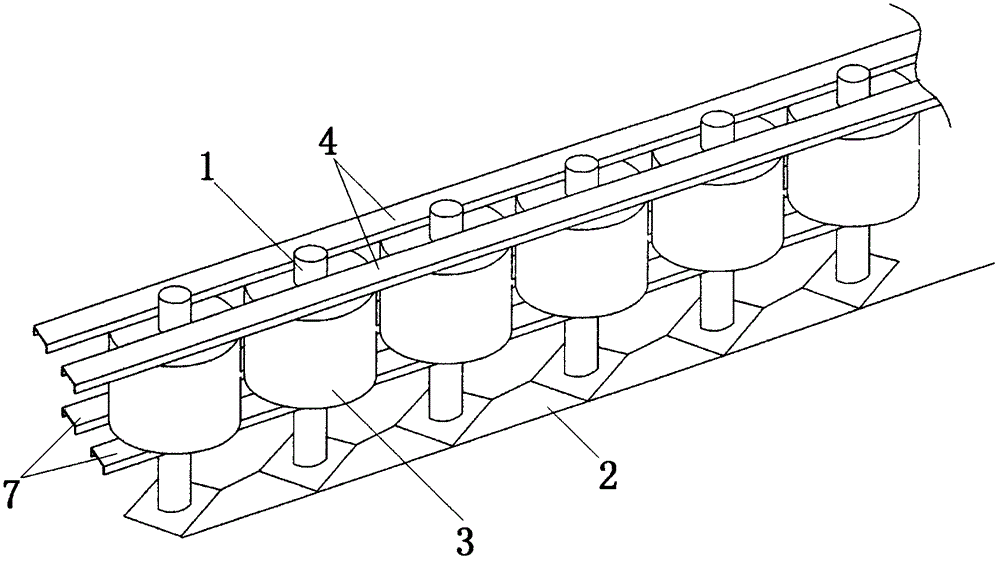

[0036] Such as image 3 As shown: on the one hand, in order to further strengthen the overall strength of the guardrail, and on the other hand, in order to save the material of the flexible roller 3 (the lower part of the flexible roller 3 has no effect), this embodiment designs the lower connecting belt 7, the lower connecting belt 7 and the main shaft The fixing method can also be one-piece molding, bolt connection, bolt connection, welding, riveting and other methods. The setting of the lower connection belt 7, in addition to enhancing the overall strength of the guardrail, can also play a role in supporting the flexible drum 3,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com