Repair method and structure for aged hydraulic engineering asphaltic concrete anti-seepage face slab

An asphalt concrete and anti-seepage panel technology, which is applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of reducing the seepage resistance of dams, affecting the safe operation of water conservancy and hydropower projects, and aging of anti-seepage panels, so as to ensure the structure Stability and anti-seepage ability, improve anti-seepage ability, delay aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

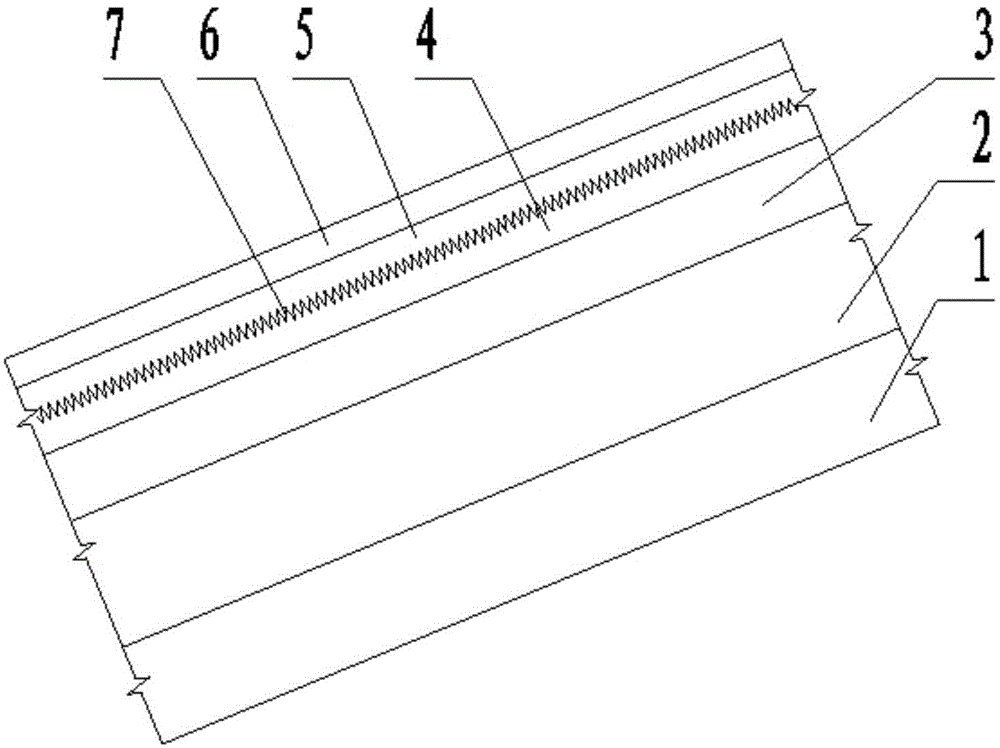

[0019] Embodiment one. structured as figure 1 shown. A method for repairing the aging of hydraulic asphalt concrete anti-seepage panels, comprising the following steps:

[0020] a. Grinding off the aging layer, using an attritor equipped with tooth grooves on the grinding disc to grind off the aging layer of the anti-seepage layer 4 .

[0021] b. Grinding at the cracks, a slope surface is ground between the cracks and the non-cracks for transition, and the thickness d of the cracks is greater than or equal to the crack depth;

[0022] c. The interface is formed, using a grinder provided with tooth grooves on the grinding disc to grind out a jagged interface 7 on the surface of the anti-seepage layer 4 after the aging layer is removed;

[0023] d. The anti-seepage layer 4 is repaired, and the anti-seepage layer 4 is repaired on the jagged interface 7 to form the anti-seepage repair layer 5. The thickness of the anti-seepage repair layer 5 is D=d+d1, and d1 is 0mm to 50mm . ...

Embodiment 2

[0027] Embodiment two. A method for repairing the aging of hydraulic asphalt concrete anti-seepage panels, comprising the following steps:

[0028] a. Grinding away the aging layer, using a grinder with a tooth groove on the grinding disc to remove the aging layer of the anti-seepage layer 4, first extracting a core sample with a diameter of 10cm at the aging place of the anti-seepage layer 4, and then measuring the core sample If the length of the upper aging part is 20mm, then the thickness of the aging layer is 20mm.

[0029] b. Grinding at the cracks, grinding a slope surface between the cracks and no cracks for transition, the slope of the slope is equal to 20%, and the thickness of the cracks is equal to the crack depth;

[0030] c, the interface is formed, using a grinder provided with tooth grooves on the grinding disc to grind out a jagged interface 7 on the surface of the anti-seepage layer 4 after the aging layer is removed, the tooth height of the zigzag interface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com