Paraffin removal and viscosity reduction device for oil well

A technology for wax removal and viscosity reduction, applied in the direction of isolation devices, cleaning tools, boreholes/well components, etc., can solve problems such as large set value, manual temperature setting, and too simple system control method, so as to avoid energy the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

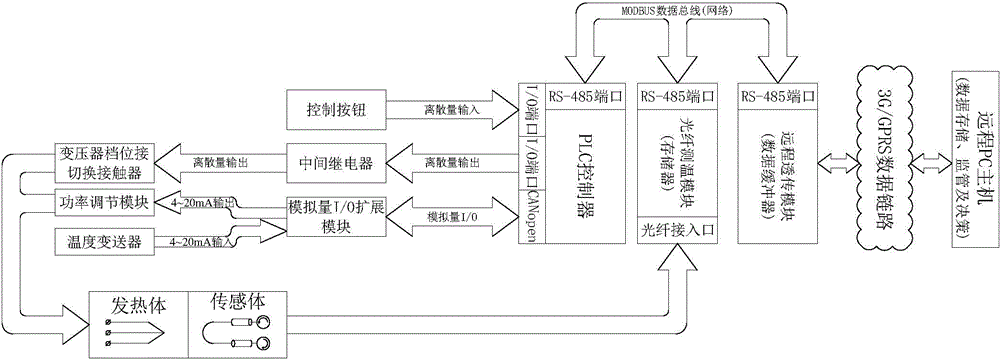

[0087] Below, a specific example of the present invention is given: the PLC controller adopts the Twido integrated type of Schneider Electric (Germany Schneider), the optical fiber temperature measurement module uses the KF2000 of Agilent in the United States, and the remote transparent transmission module uses the MD-209G of Yitang Technology. The PC host uses a compatible machine, the power supply uses a custom transformer with 10 sets of taps, the power adjustment module uses Zibo Kailong's MJYS-QKJL-150, and other electrical components are selected according to national standards. The analog I / O expansion module uses TM2AMM6HT, and the temperature transmitter uses Tean intelligent temperature transmitter W4052. The on-site control cabinet is mainly composed of PLC controller, optical fiber temperature measurement module and remote transparent transmission module, among which PLC control is the core. The upper part is a data buffer that communicates with the upper computer;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com