Method for judging geological layer where drill of drilling machine where drill of drilling machine drilling for certain depth is positioned

A geological layer and depth technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve the problems that the physical properties and mechanical parameters of rock formations cannot be obtained, the progress is restricted, and it is difficult to obtain cores, etc., so as to simplify the physical The process of properties and mechanical parameters, the effect of saving engineering costs and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above-mentioned objects and advantages of the present invention can be more clearly understood by referring to the detailed description of the preferred embodiments of the present invention with reference to the accompanying drawings.

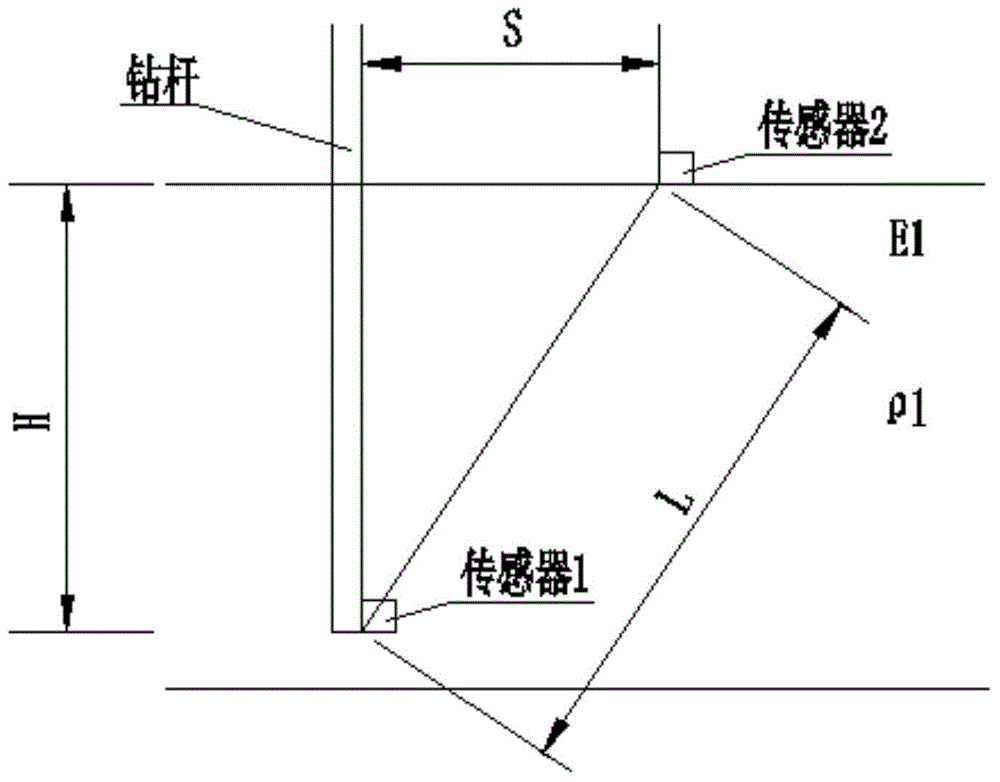

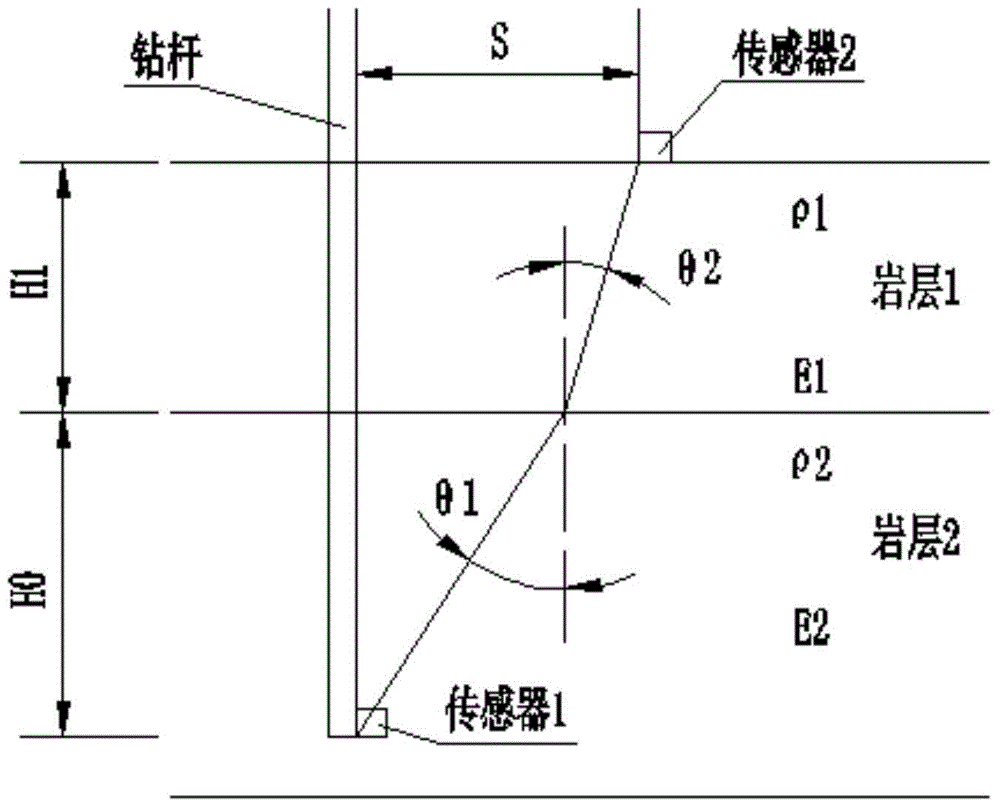

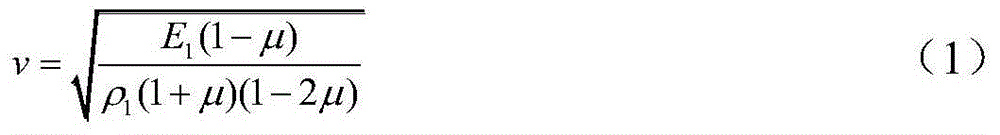

[0033] Such as figure 1 As shown, when the drill pipe is running in the rock formation, measure the P wave generation time t of the sensor 1 installed on the drill bit 1 and the P-wave arrival time t of surface sensor 2 2 , according to the geometric relationship, the propagation distance of P wave can be obtained Then by V=L / (t 2 -t 1 ) can obtain the propagation velocity v of P wave in rock formation 1. The rock core is sampled and collected to determine its density, and the relationship between elastic modulus, P wave propagation velocity and rock density

[0034] v = E 1 ( 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com