Self-cleaning method for EGR valve

An EGR valve, self-cleaning technology, used in electrical control, machine/engine, fuel injection control, etc., can solve problems such as inability to effectively remove carbon deposits, dirt, EGR valve deposits, and inability to achieve self-cleaning purposes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the present invention is to provide a self-cleaning method for an EGR valve, through which deposits accumulated in the EGR valve can be effectively eliminated, a stable and reliable working state of the EGR valve can be ensured, and its service life can be improved.

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

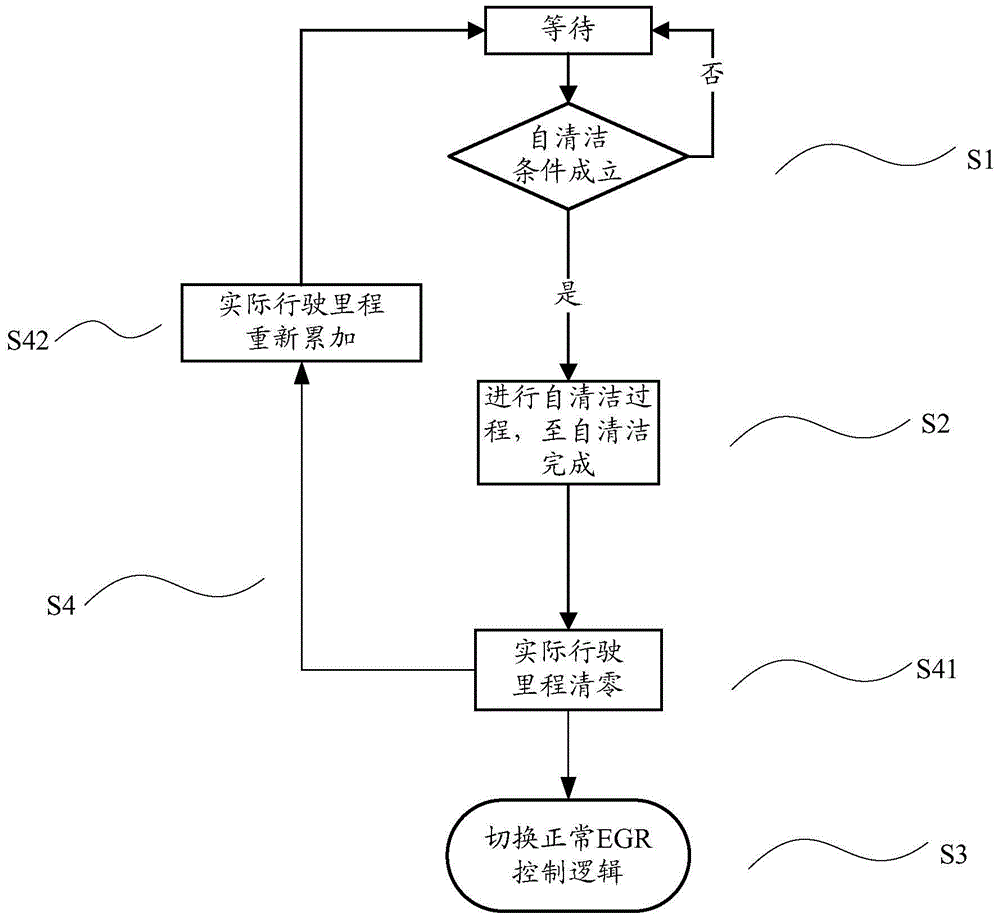

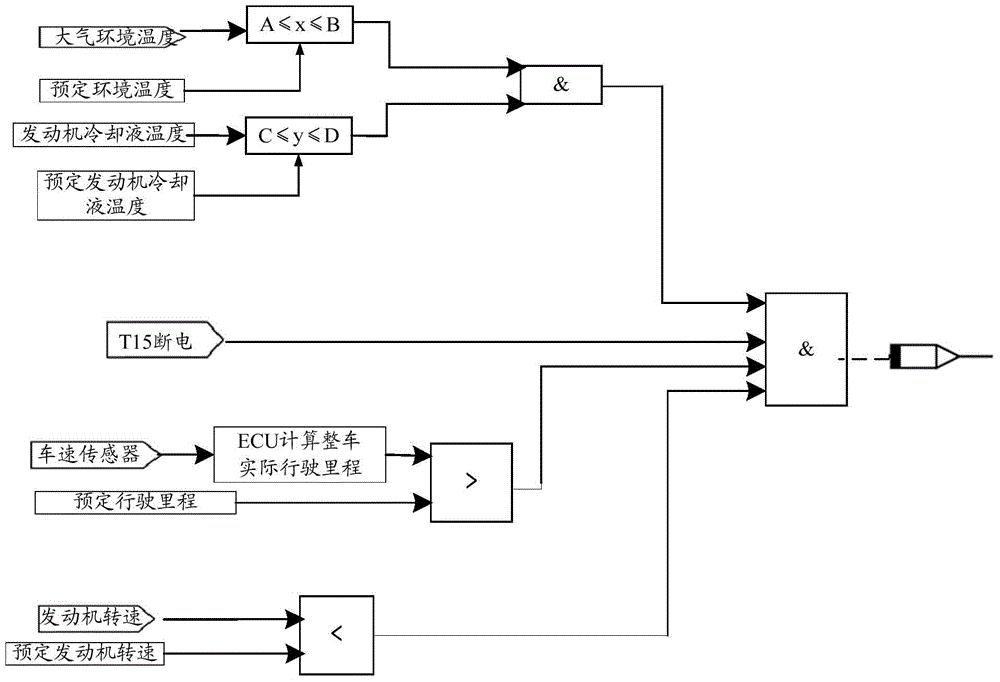

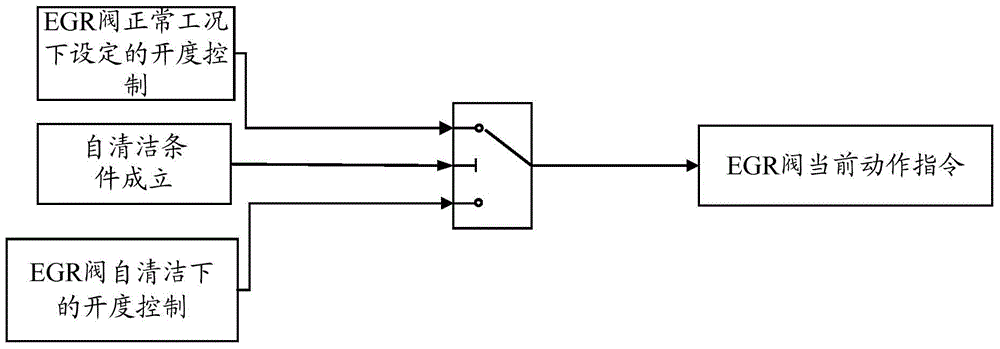

[0030] Please refer to figure 1 , figure 2 ,in, figure 1 It is the control logic diagram of the EGR valve self-cleaning in the specific embodiment; figure 2 It is a logical diagram of activation conditions of EGR valve self-cleaning in a specific embodiment.

[0031] The invention provides a self-cleaning method of an EGR valve, and the ECU of the engine controls the action of the EGR valve. In a specific embodiment, such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com