Flat tube fin penetrating type micro-channel evaporator for direct-cooling refrigerator

A direct-cooling refrigerator and micro-channel technology, applied in the field of heat exchange, can solve the problems of unfavorable defrosting and drainage, poor application of refrigerator air ducts, etc., and achieve the effect of less pipe material usage, convenient assembly, and less filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

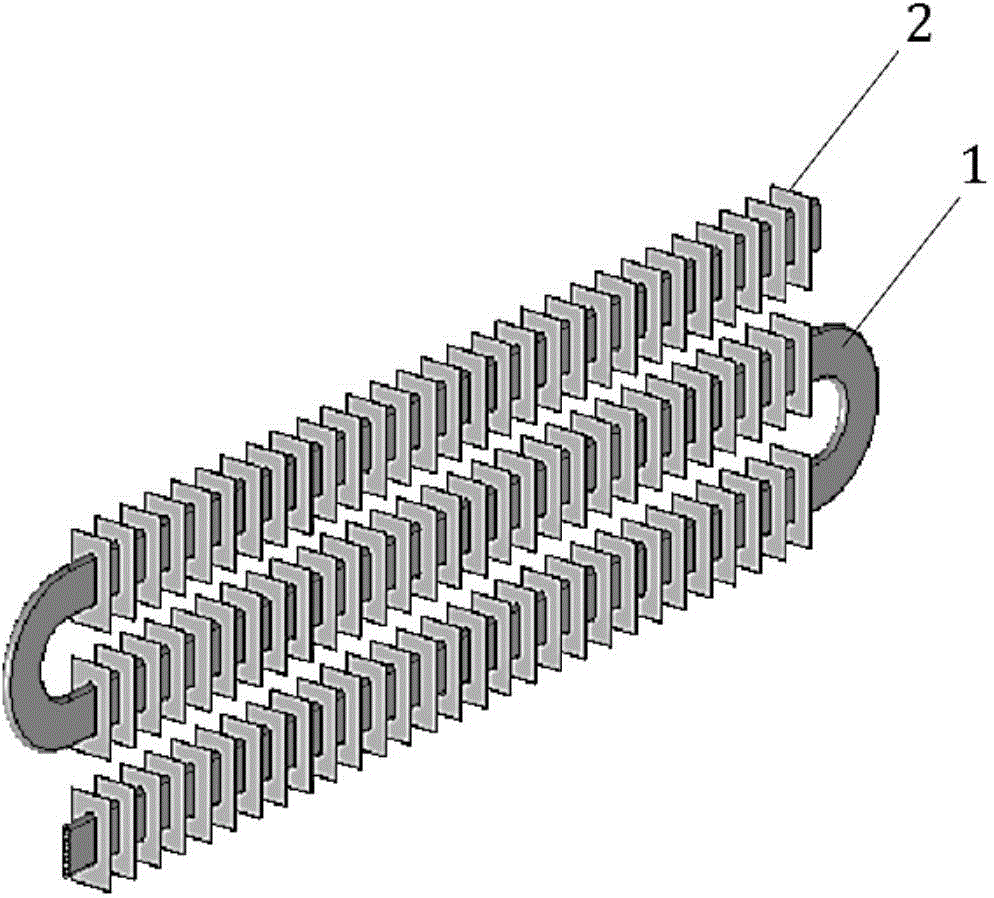

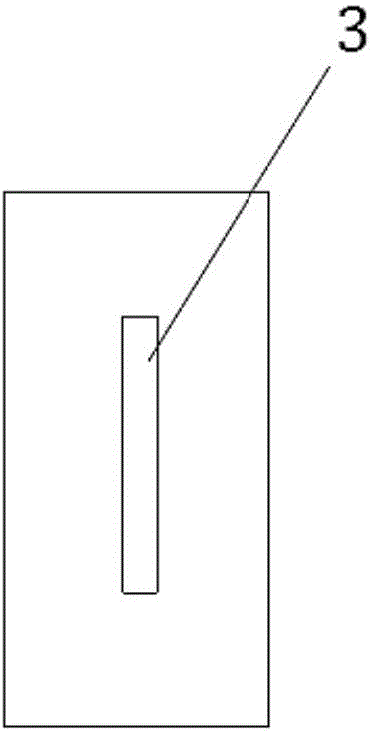

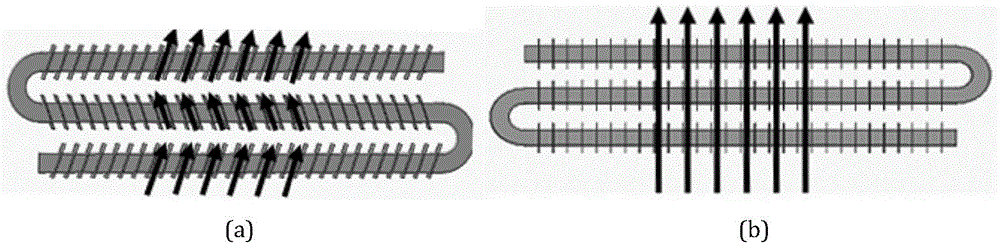

[0025] Such as figure 1 As shown in -4, this embodiment includes: microchannel flat tube 1, rectangular heat sink 2, wherein: the center of the rectangular heat sink 2 has a hole 3 with the same shape and cross-sectional area as the flat tube 1, and the microchannel flat tube 1 vertically passes through the hole 3 in the center of the rectangular heat sink, especially the different layers and different rows of flat tubes 1 pass through independent heat sinks 2, and the heat sinks are not connected together. This design makes the evaporator more suitable for the refrigerator air duct with special structure when it is twisted and installed, and it is easier to defrost and drain water.

[0026] During processing, the aluminum strip with good thermal conductivity is stamped into heat-exchanging rectangular heat sinks 1, and rectangular holes 3 with an area slightly larger than the microchannel flat tube are punched out at equidistant positions on it, and the rectangular heat sinks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com