A method for testing and diagnosing the causes of lithium-ion battery performance attenuation

A lithium-ion battery and diagnostic method technology, which is applied in the field of testing and diagnosis of the causes of lithium-ion battery performance attenuation, can solve problems such as deviation from the original state of the battery, insufficient sensitivity, and influence on judgment results, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

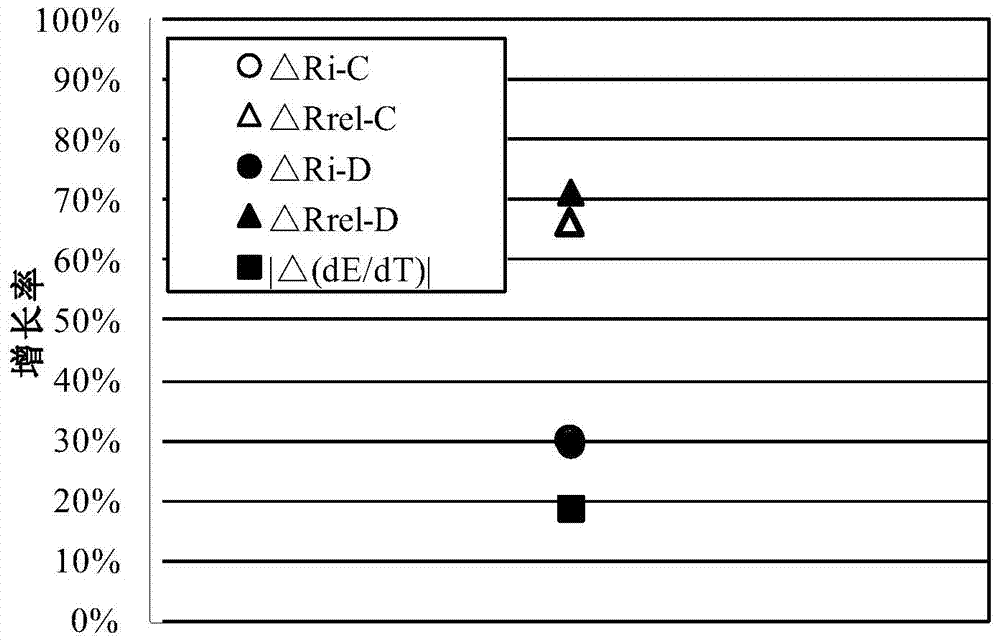

[0033] The test battery model is 18650 cylindrical battery, the reference battery capacity is 2500mAh (1C=2500mA), and the 0.5C discharge capacity retention rate of the battery to be tested is 80% (350 cycles), that is, 2000mAh (1C=2000mA).

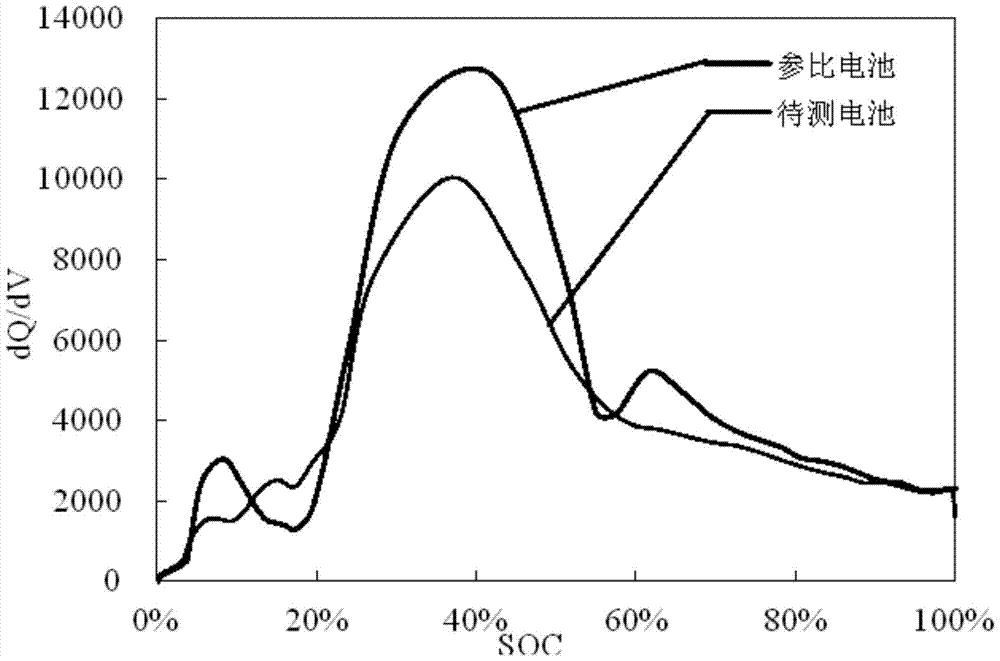

[0034] First, take the battery to be tested and the reference battery, and conduct a 0.1C capacity test on the Arbin charge-discharge instrument, and draw the dQ / dV vs. state of charge (SOC) curve of the battery according to the voltage and capacity data, as shown in figure 1 shown by figure 1 It can be seen that the main electrochemical reaction range of the system battery corresponds to a battery charge state range of 25%-55%, and in this embodiment, the preferred charge state range is 40%.

[0035] 1) Measure the ohmic impedance and relaxation impedance of the battery during charging (discharging):

[0036] Charge with a small current of 0.1C for 4h (discharge for 6h) to 40% state of charge, then charge (discharge) with a current of 1...

Embodiment 2

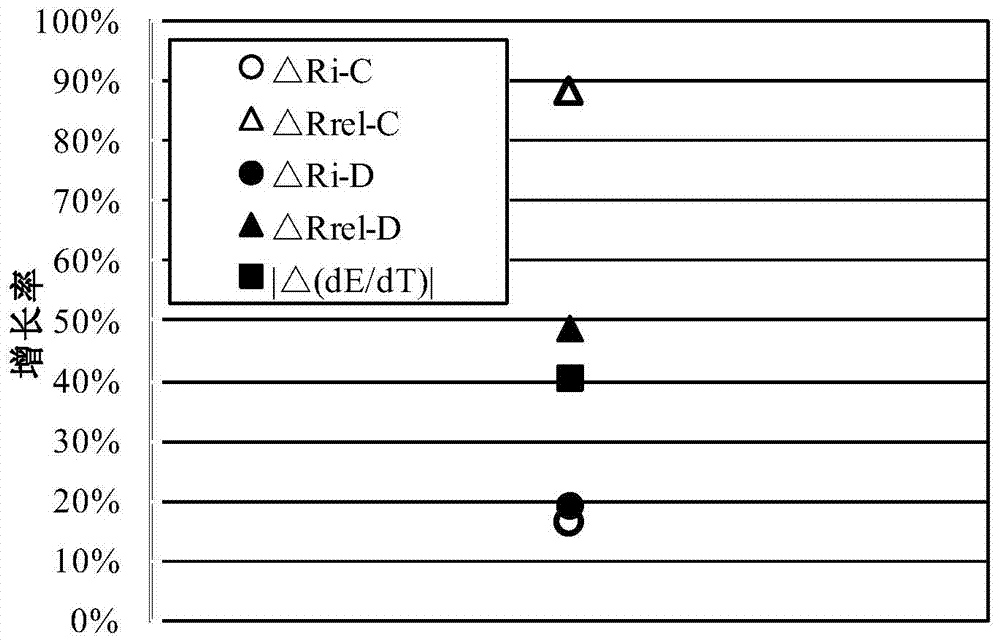

[0047] In this embodiment, the test battery model is a 18650 cylindrical battery, the reference battery capacity is 2300mAh (1C=2300mA), and the 0.5C discharge capacity retention rate of the battery to be tested is 80% (800 cycles), that is, 1840mAh (1C = 1840mA).

[0048] In this embodiment, the SOC interval of the direct selection test is 40%.

[0049] 1) Measure the ohmic impedance and relaxation impedance of the battery during charging (discharging):

[0050] The method of measuring the ohmic impedance and relaxation impedance of the battery during the charging (discharging) process is to charge with a small current of 0.1C for 4h (discharge for 6h) to 40% state of charge, then charge (discharge) with a current of 1C for 1s, and collect voltage data The interval is 60ms, and the last voltage value is recorded as Uo, sleep, within 1s after sleep starts, the interval of collecting voltage data is 60ms, the first collected voltage value is recorded as Ui, and the collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com