Finite element simulation method for shot-peening strengthening deformation based on ABAQUS

A shot peening, simulation method technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of predicting part deformation, complex repeated iteration process, large amount of calculation, etc., to achieve low cost and application effect. good, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

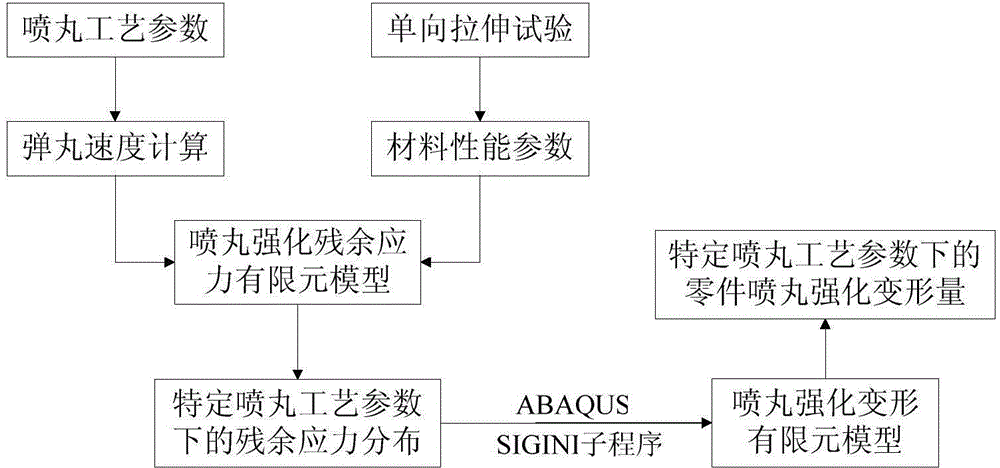

[0030] This embodiment is a finite element simulation method of shot peening deformation based on ABAQUS.

[0031] refer to Figure 1 ~ Figure 4 , the part in this embodiment is a kind of aircraft flange part, the main load-bearing structural part of the butt joint of the central wing and the outer wing. The structure of this part is complex and the process is difficult. The assembly butt joint has a key influence, and the material of the edge part is 2026-T3511 aluminum alloy.

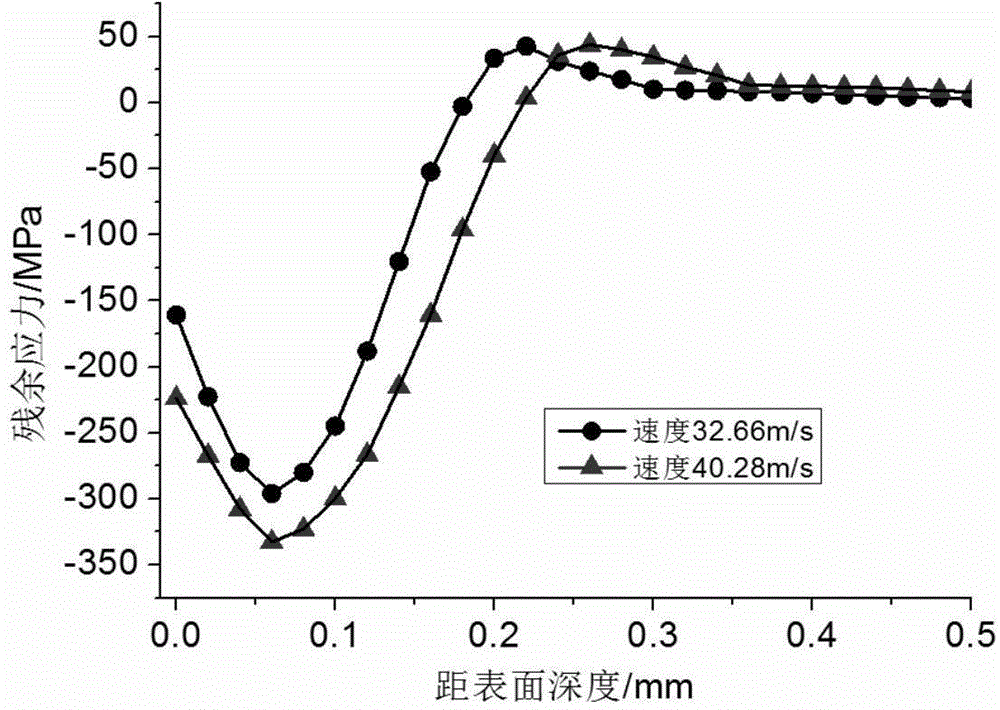

[0032] (1) Finite element simulation of shot peening residual stress

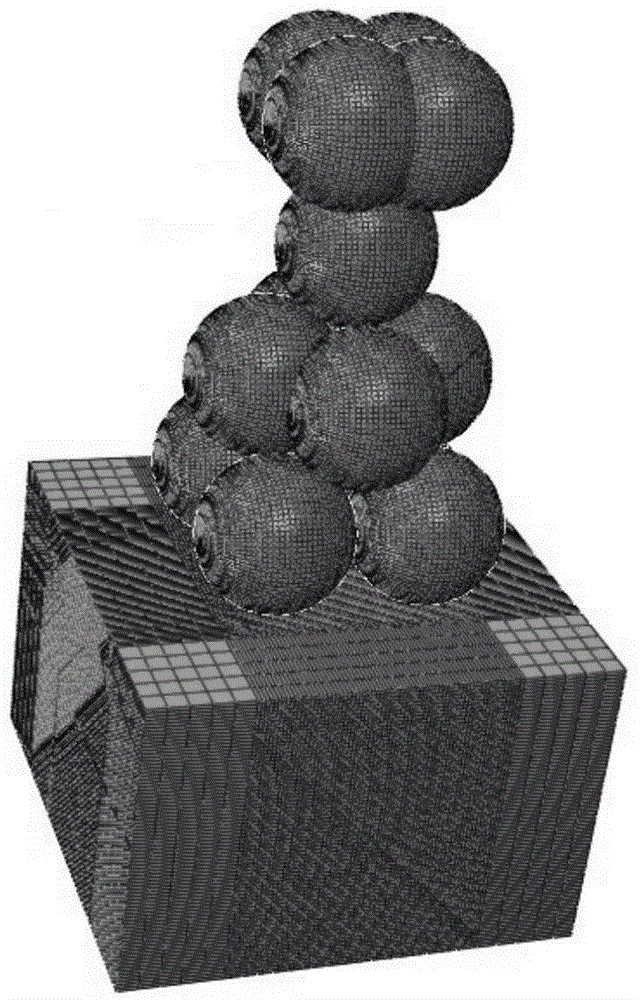

[0033] In the ABAQUS dynamic display analysis, the impact load generated during the collision between the projectile and the surface of the sprayed test piece is simulated by defining the initial velocity of the projectile, and the Coulomb friction model is used to describe the contact between the projectile and the sprayed test piece. The tangential motion between the two contact surfaces is reduced to make the calculated result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com