Solar battery backboard removing and delivering apparatus

A technology for solar cells and backplanes, which is applied to circuits, electrical components, conveyor objects, etc., can solve the problems of easy breaking, the backplane is not easy to be divided into pieces, and the handling efficiency is low. Convenient, safe, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

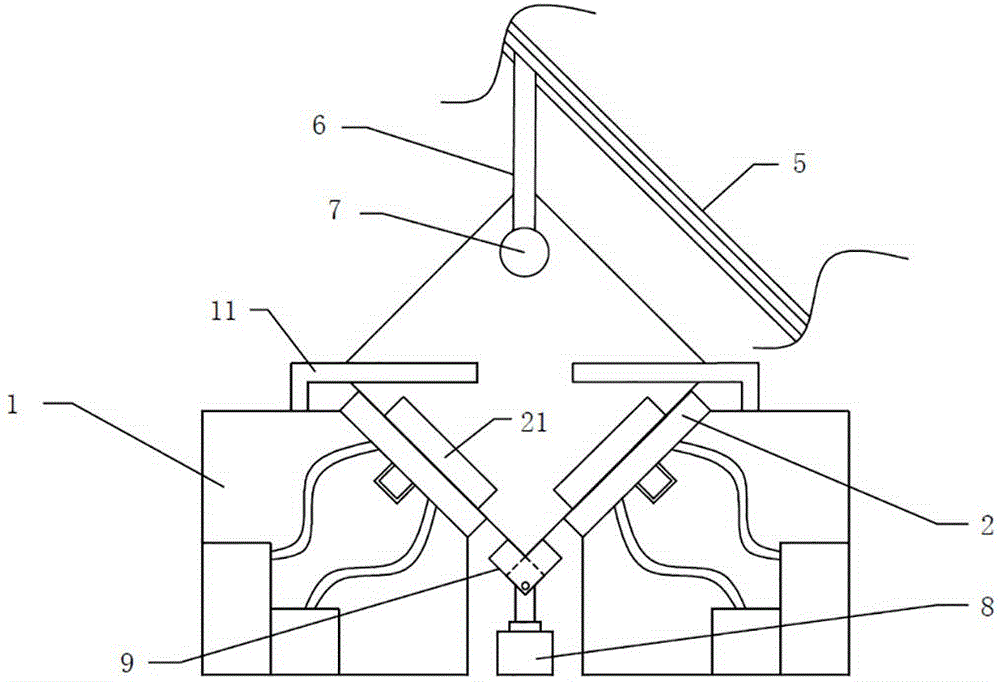

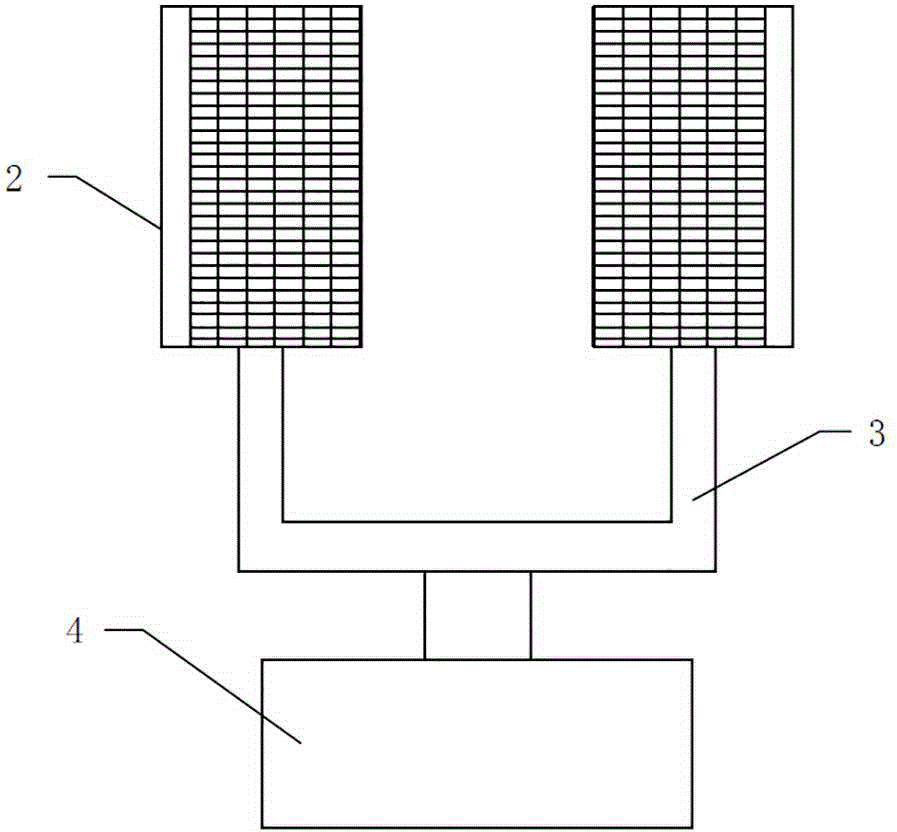

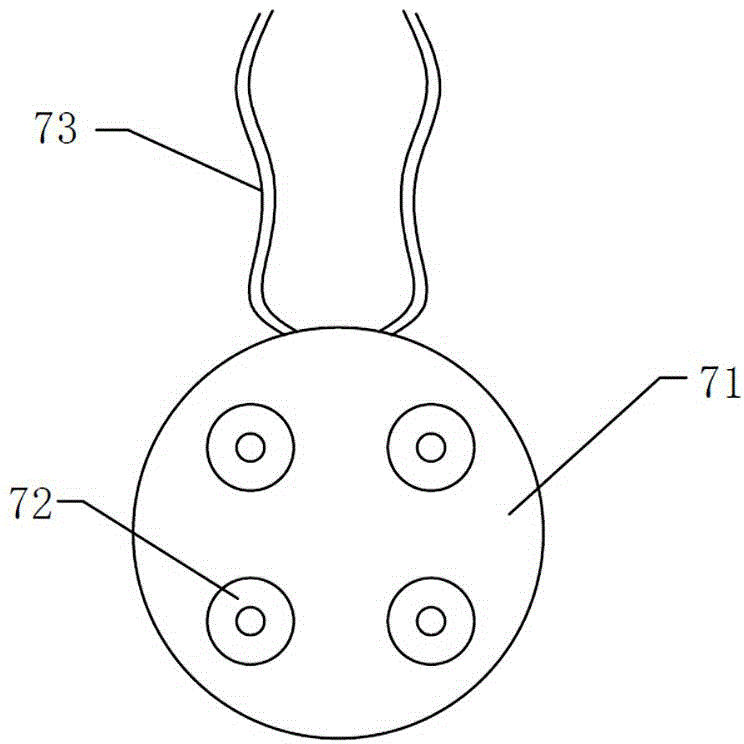

[0020] See figure 1 , figure 2 and image 3 , an embodiment of a solar battery backplane pick-up and delivery device, including a base 1, a backplane storage mechanism slidably connected to the base 1, a driving mechanism for moving the backplane storage mechanism, and a backplane storage mechanism Coordinated fragment pick-up and delivery mechanism.

[0021] The backboard storage mechanism includes a backboard support plate 2 slidably connected to the machine base 1. The backplane support plate 2 is hollow inside and connected with a compressed gas inlet pipe. The surface of the backboard support plate 2 is provided with a compressed gas outlet. An external air pump can be arranged in the base 1, and the compressed gas can be dry warm gas or plasma gas. The compressed air vents can be fence-type air ports, point-like distribution air ports, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com