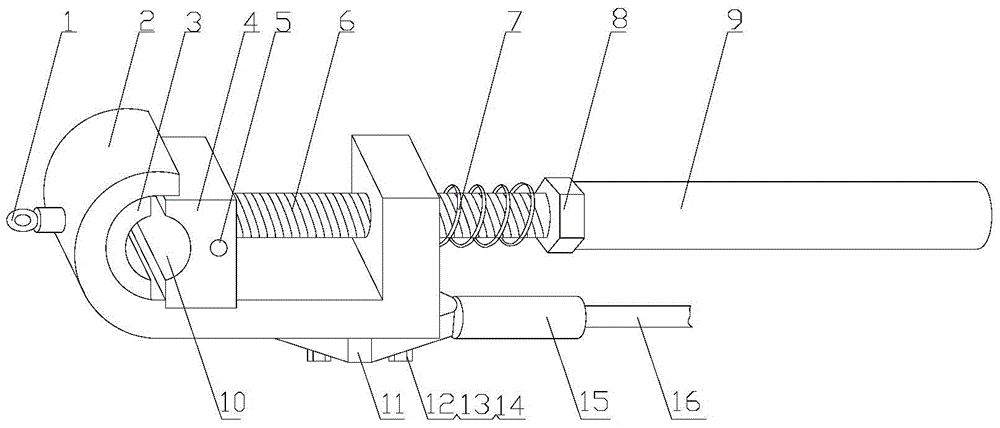

Portable 120-to-400mm2 aluminum conductor steel reinforced cable shunting clamp and use method thereof

A steel-cored aluminum stranded wire and shunt wire technology, which is applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of steel-cored aluminum stranded wire specification and cross-section change, etc., to improve the reliability of power supply, protect people and electrical equipment Safe, easy to transport and store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

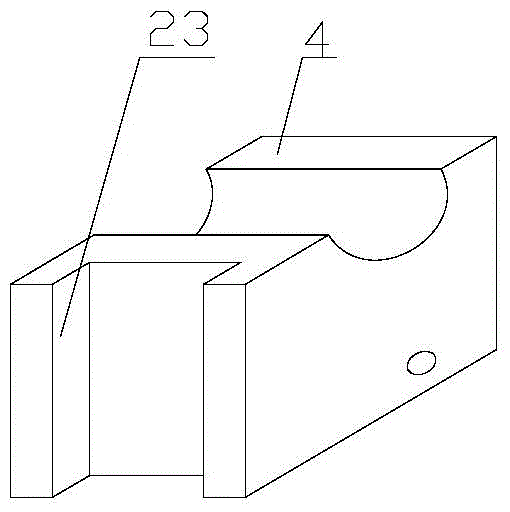

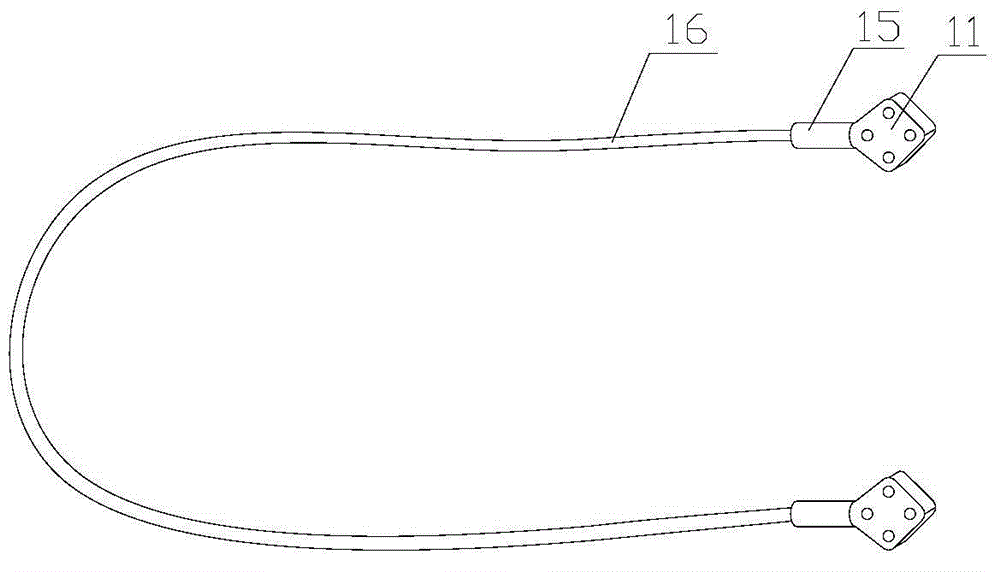

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Taking the heating of 66kV busbar contacts as an example

[0049] A portable 120-400mm 2 The operation method of the steel core aluminum stranded wire shunt line fixture is to lift the above fixture to the working position of the busbar, horizontal busbar, and herringbone line heating contact, and keep a safe distance for live work at the corresponding voltage level. The specific operation steps of live direct connection or short connection are as follows:

[0050] 1. On-site survey, according to the survey results to make a judgment on the section specification of the drainage line between the busbar and the circuit.

[0051] 2. Determine the live working method and determine the access for workers to go up and down the insulating ladder.

[0052] 3. Determine the lifting channel of the shunt line fixture and the measures to be taken.

[0053] 4. The inspection and test of insulating tools are qualified, the equipotential electrician shielding clothing is...

Embodiment 2

[0065] Example 2: Take the heating of 220kV busbar contacts as an example

[0066] A portable 120-400mm 2 The operation method of the steel core aluminum stranded wire shunt line fixture is to lift the above fixture to the working position of the busbar, horizontal busbar, and herringbone line heating contact, and keep a safe distance for live work at the corresponding voltage level. The specific operation steps of live direct connection or short connection are as follows:

[0067] 1. On-site survey, according to the survey results to make a judgment on the section specification of the drainage line between the busbar and the circuit.

[0068] 2. Determine the live working method and determine the access for workers to go up and down the insulating ladder.

[0069] 3. Determine the lifting channel of the shunt line fixture and the safety measures that should be taken.

[0070] 4. The inspection and test of insulating tools are qualified, the equipotential electrician shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com