Automatic power-on intelligent-type electric leakage protector

A leakage protector and automatic power-on technology, applied in the direction of automatic disconnection emergency protection device, emergency protection circuit device, electrical components, etc., can solve the problems of leakage protector electric shock, affecting personal safety and other problems, and improve energy saving effect. , Eliminate potential safety hazards and increase the effect of self-checking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

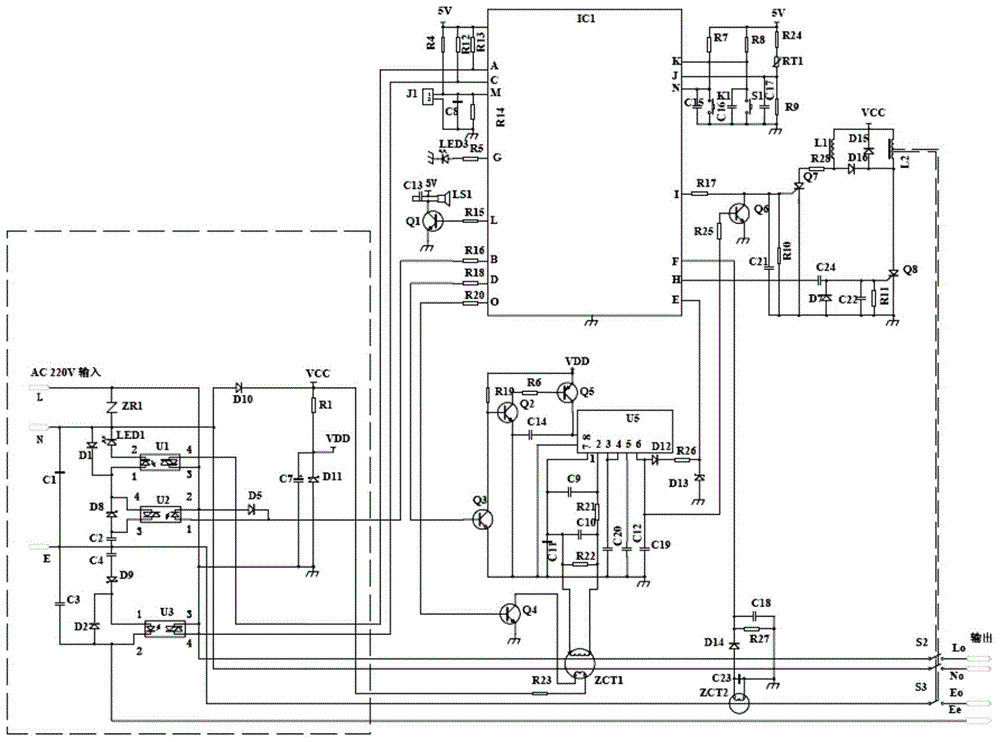

[0029] Such as figure 1 As shown, the present invention proposes an automatic power-on intelligent leakage protector, including a live wire L, a neutral wire N, a ground wire E, a tripping device, a rectifying and stabilizing circuit (rectifying diode D10), an amplifying circuit U5, and an amplifying circuit The zero-sequence transformer ZCT1 and the ground wire E transformer connected by U5 also include optocoupler U1, optocoupler U2, optocoupler U3 and single-chip microcomputer IC1; pin 2 of the optocoupler U1 is electrically connected to the neutral line N, and the optocoupler The pin 1 of U1 is connected to the pin 4 of the optocoupler U2, the pin 4 of the optocoupler U1 is connected to the A pin of the single-chip microcomputer IC1, and the pin 3 of the optocoupler U1 is connected to the pin 2 of the optocoupler U2; The pin 1 of the coupler U2 is connected to the B pin of the single-chip microcomputer IC1, and the pin 3 string C2 of the optocoupler U2 is electrically conn...

Embodiment 2

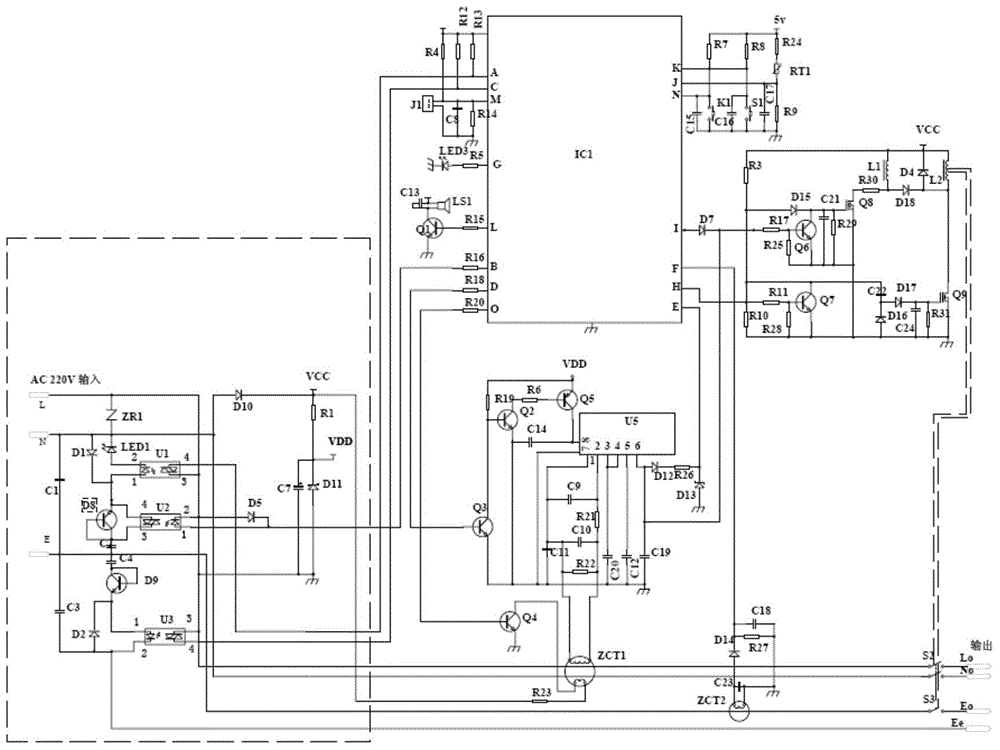

[0087] The implementation process and method of this embodiment and Embodiment 1 are basically the same, the difference is:

[0088] The regulator tubes D8 and D9 in the first embodiment are replaced by triodes D8 and D9; the silicon controlled rectifiers Q7 and Q8 can be replaced by field effect transistors Q8 and Q9, and their peripheral circuits are appropriately modified. Circuit schematic diagram see figure 2 .

Embodiment 3

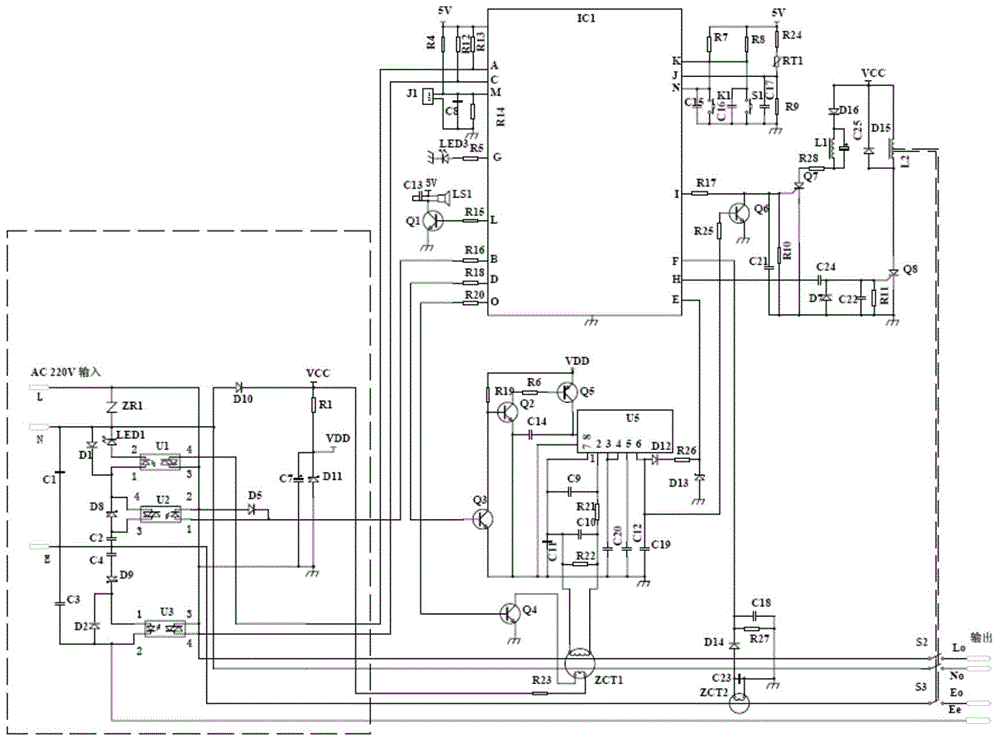

[0090] The implementation process and method of this embodiment and Embodiment 1 are basically the same, the difference is:

[0091] The diode D16 is connected in series with the sustaining coil L1, and an energy storage capacitor C25 is connected in parallel with the sustaining coil L1 to provide stable energy for the sustaining coil L1 and prevent the sustaining coil L1 from generating noise. Refer to the specific circuit schematic diagram image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com