An automatic feeding system for chemical production

A technology for automatic feeding and chemical production, which is applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc. It can solve the problems of poor control accuracy, many on-site operators, and high production costs, so as to avoid measurement and control error, reducing on-site operators, ensuring fluidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

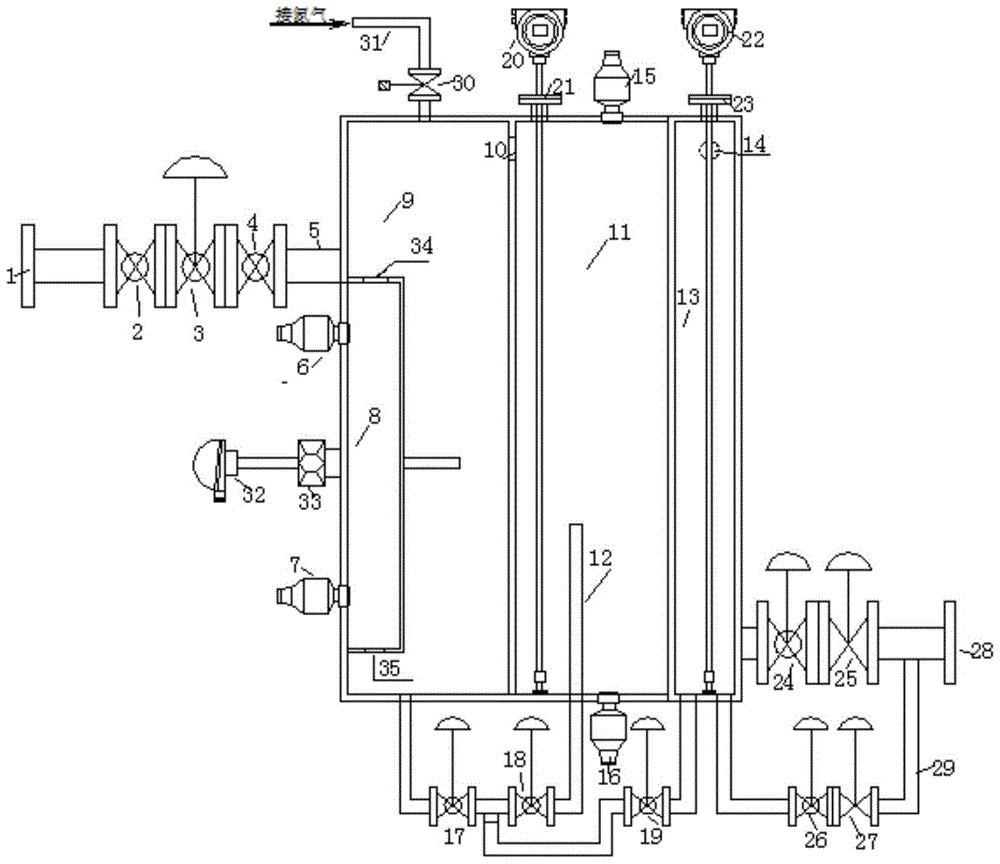

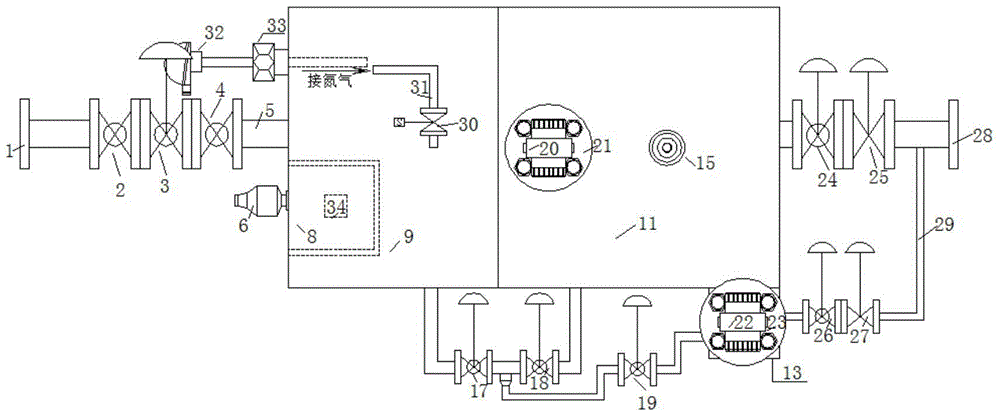

[0033] like figure 1 and figure 2 As shown, an automatic feeding system for chemical production includes feeding components, and also includes online density measurement components, temperature measurement components, liquid level measurement components, flow sensor components and pressure protection system components.

[0034] The feed assembly includes inlet connection flange 1, primary valve 2, pneumatic switch valve 3, valve 4, connecting short pipe 5 and feed material box 9;

[0035] The online density measurement assembly includes an upper pressure sensor 6, a lower pressure sensor 7 and a built-in volume box 8;

[0036] The temperature measurement assembly includes a thermal resistance 32 and a thermal resistance base 33;

[0037] Liquid level measurement components include pneumatic discharge valve 17, large material box feed valve 18, feed pipe 12, large material box magnetostrictive liquid level gauge 20, small material box feed valve 19, small material box magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com