Preparation method of carbon/carbon nano tube composite foam adsorption material

A carbon nanotube composite and foam adsorption technology, applied in the field of materials, can solve problems such as harmfulness and the difficulty of absorbents to meet requirements, and achieve the effects of short experimental period and simple and reliable preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

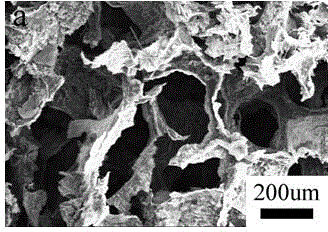

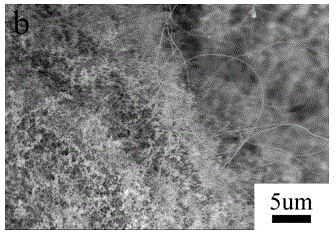

Image

Examples

Embodiment 1

[0027] (1) Disperse 0.5g of purchased acidified carbon nanotubes into 25g of a mixed solvent of ethanol and water with a volume ratio of 1:3, and disperse for 10 minutes under ultrasonic conditions with a power of 400W to obtain a carbon nanotube mixture. The concentration of carbon nanotubes in the carbon nanotube mixture liquid is 2wt%.

[0028] (2) Weigh 10g of phenolic resin and 1g of curing agent hexamethylenetetramine and mix them with 40g of ethanol solvent, and form a 20wt% mixture of phenolic resin after 30 minutes under ultrasonic conditions with a power of 400W.

[0029] (3) Cut and weigh 1g of a polyurethane foam template with a thickness of 4mm, and repeatedly and evenly absorb the above two mixed solutions: first absorb the carbon nanotube mixed solution, then dry it at 60°C, and then absorb the phenolic resin mixed solution, Repeat 3 to 5 times, and ensure that the last time is to absorb the phenolic resin mixture until the template is cross-linked and solidifie...

Embodiment 2

[0034] (1) Disperse 1.35g of purchased acidified carbon nanotubes into 25g of a mixed solvent of ethanol and water with a volume ratio of 1:2, and disperse for 10 minutes under ultrasonic conditions with a power of 400W to obtain a carbon nanotube mixture. The concentration of carbon nanotubes in the carbon nanotube mixture liquid is 5wt%.

[0035] (2) Weigh 20g of phenolic resin and 2g of curing agent hexamethylenetetramine and mix with 46g of ethanol solvent, and form a 30wt% mixture of phenolic resin after 30 minutes under ultrasonic conditions with a power of 400W.

[0036] (3) Cut and weigh 2.7g of a polyurethane foam template with a thickness of 4mm, and repeatedly and evenly absorb the above two mixed solutions: first absorb the carbon nanotube mixed solution, then dry it at 60°C, and then absorb the phenolic resin mixed solution , repeated 4 times, and ensured that the last time was to absorb the phenolic resin mixture until the template was cross-linked and solidified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com