A method for preparing metal matrix composites using 3D printing space structure

A space structure and composite material technology, applied in the field of metal matrix composite materials, can solve the problems of difficult preparation and control, and achieve the effect of large infiltration depth, dense structure and good interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of ball -stacking space structure tough steel base composite materials

[0032] The specific steps of using 3D printing space structure to prepare metal base composite materials are as follows:

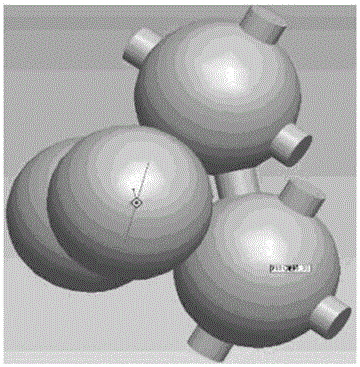

[0033] Step 1. First use the Solid Edge drawing software to draw the three -dimensional model of the required spatial structure. The three -dimensional model of the required space structure is figure 1 The sphere stacked space structure, the diameter of the sphere is 2.5mm, and the body heart cubic stack; the length of the link rod is 1mm and the diameter is 1mm. The space structure drawn by a 3D printer is printed into a spatial structure plastic template;

[0034] Step 2, mix the ceramic particles and adhesives into a pulp, then pour the slurry into the physical part of the space structure plastic template in the step 1, and then burn the plastic to the ceramicsGranules pre -made, high -temperature sintering temperature is determined by the type and pressure immersion...

Embodiment 2

[0037] Preparation of tough steel -based composite materials for the structure of the hexagonal hexainet stacking space

[0038] The specific steps of using 3D printing space structure to prepare metal base composite materials are as follows:

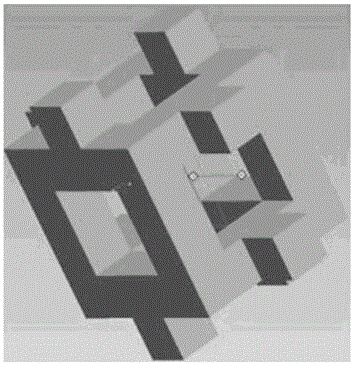

[0039] Step 1. First use the ProE drawing software to draw the three -dimensional model of the required space structure. The three -dimensional model of the required spatial structure is Figure 5 Zhongzheng Hexagonal Packing Space Structure, the edge of the cross -sectional gap is 2.5mm, and the thickness of the physical part is 1.8mm. The 3D printer is printed to print the space structured plastic template;

[0040] Step 2, mix the ceramic particles and adhesives into a pulp, then pour the slurry into the gap of the space structure plastic template in the step 1, and then burn the plastic to the ceramicsGranules pre -made, high -temperature sintering temperature is determined by the type and pressure immersion method of bonding agent; the ...

Embodiment 3

[0043] Preparation of dual -spiral space structure metal base base composite materials

[0044] The specific steps of using 3D printing space structure to prepare metal base composite materials are as follows:

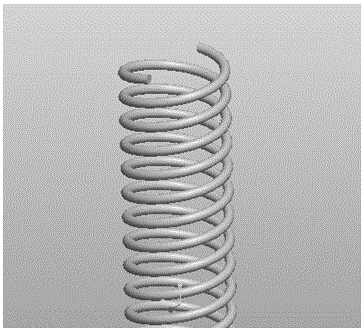

[0045] Step 1. First, use the ProE drawing software to draw the three -dimensional model of the required spatial structure. The three -dimensional model dual spiral structure of the required spatial structure, such as image 3 Show, the spiral radius is 1.8mm and the distance is 2mm.Use a 3D printer to print the painted spatial structure into a spatial structure plastic template;

[0046] Step 2. Put the ceramic particles and adhesives into a pulp, and then irrigate the slurry into the inside hollow parts of the entity of the space -structured plastic template in the step 1, and then burn the plastic to burn the plastic sintering of the space structure of the plastic structure of the slurry.Get ceramic particles prefabricated, and the temperature of high -temperature sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com