A drainage pavement structure with functions of deicing and snow melting

A pavement structure and function technology, applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of high investment cost, high maintenance cost, and coating wear, so as to achieve low construction and maintenance costs and increase traffic. Safety and the effect of increasing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

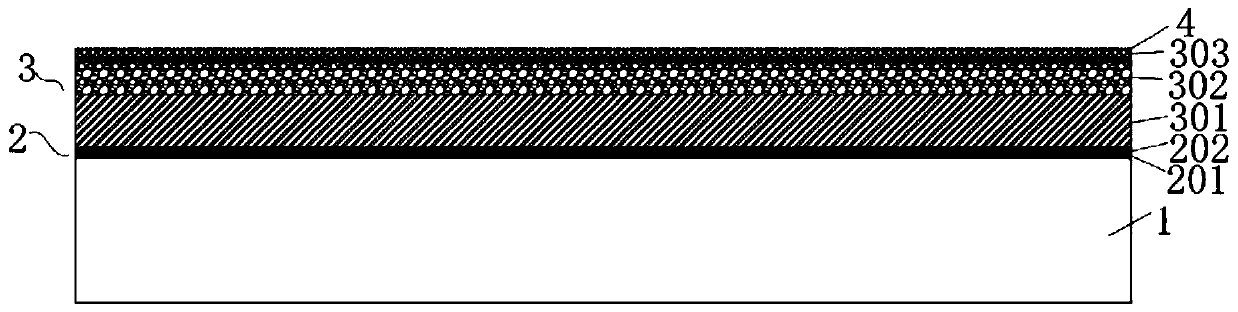

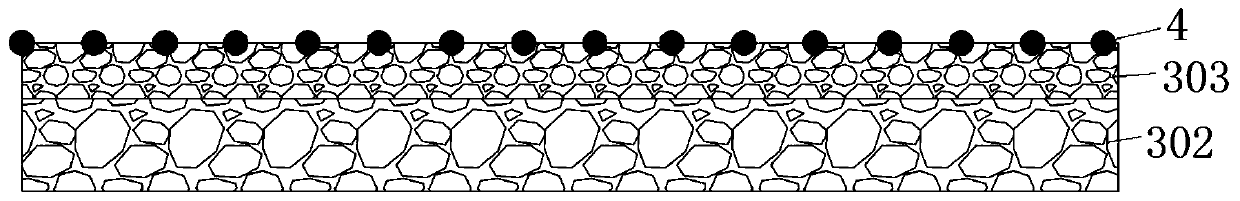

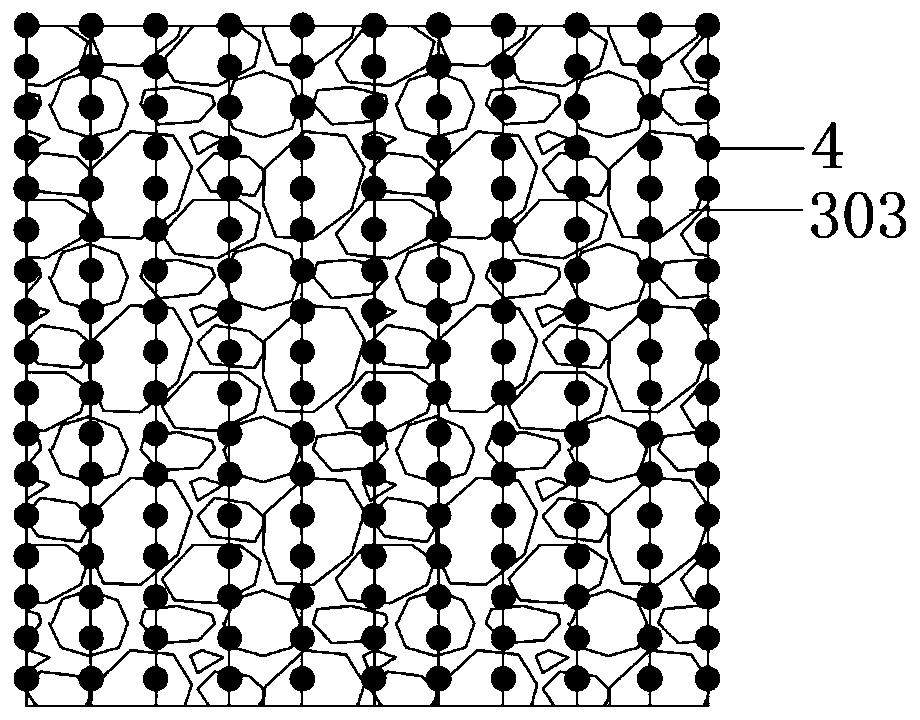

[0039] Such as figure 1 and figure 2As shown, a drainage pavement structure with the function of deicing and snow melting includes a waterproof adhesive layer 2 paved on the ground base 1, and an asphalt mixture drainage layer 3 is paved on the waterproof adhesive layer 2; the asphalt mixture The material drainage layer 3 includes a lower drainage layer 301, a middle drainage layer 302 and an upper drainage layer 303 paved sequentially from bottom to top, the lower drainage layer 301 is an asphalt mixture with a porosity of 3%, and the middle drainage layer 302 is a porosity 20% open-graded snow-melting asphalt mixture, the upper drainage layer 303 is an open-graded snow-melting asphalt mixture with a porosity of 18%, wherein the pores of the middle drainage layer 302 and the upper drainage layer 303 are connected to each other; On the layer 303 is a rubber particle layer 4, wherein the thickness of the waterproof adhesive layer 2 is 1 cm, the thickness of the lower drainage...

Embodiment 2

[0055] A drainage pavement structure with the function of deicing and snow melting, comprising a waterproof adhesive layer 2 paved on the ground base 1, the waterproof adhesive layer 2 is paved with an asphalt mixture drainage layer 3; the asphalt mixture drainage layer 3 includes a lower drainage layer 301, a middle drainage layer 302 and an upper drainage layer 303 paved in sequence from bottom to top, the lower drainage layer 301 is an asphalt mixture with a porosity of 5%, and the middle drainage layer 302 is a Open-graded snow-melting asphalt mixture, the upper drainage layer 303 is an open-graded snow-melting asphalt mixture with a porosity of 20%, wherein the pores of the middle drainage layer 302 and the upper drainage layer 303 are connected to each other; the upper drainage layer 303 It is a rubber particle layer 4, wherein the thickness of the waterproof adhesive layer 2 is 2cm, the thickness of the lower drainage layer 301 is 9cm, the thickness of the middle drainag...

Embodiment 3

[0070] A drainage pavement structure with the function of deicing and snow melting, comprising a waterproof adhesive layer 2 paved on the ground base 1, the waterproof adhesive layer 2 is paved with an asphalt mixture drainage layer 3; the asphalt mixture drainage layer 3 includes the lower drainage layer 301, the middle drainage layer 302 and the upper drainage layer 303 paved sequentially from bottom to top, the lower drainage layer 301 is asphalt mixture with a porosity of 4%, and the middle drainage layer 302 is a Open-graded snow-melting asphalt mixture, the upper drainage layer 303 is an open-graded snow-melting asphalt mixture with a porosity of 19%, wherein the pores of the middle drainage layer 302 and the upper drainage layer 303 are connected to each other; the upper drainage layer 303 It is a rubber particle layer 4, wherein the thickness of the waterproof adhesive layer 2 is 1.5cm, the thickness of the lower drainage layer 301 is 8cm, the thickness of the middle dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com