Glass fiber dispersion and guide device

A guiding device, glass fiber technology, applied in the coating and other directions, can solve the problems of low disassembly and assembly efficiency, difficult to clean up residual materials, glass fiber product performance degradation, etc., to reduce the possibility of hairiness, avoid contact and scratching The effect of rubbing and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

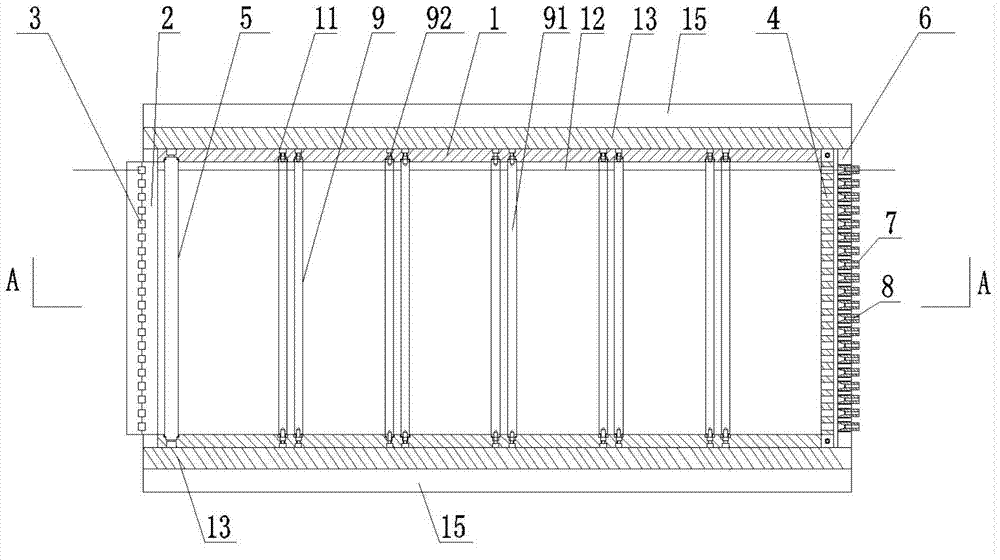

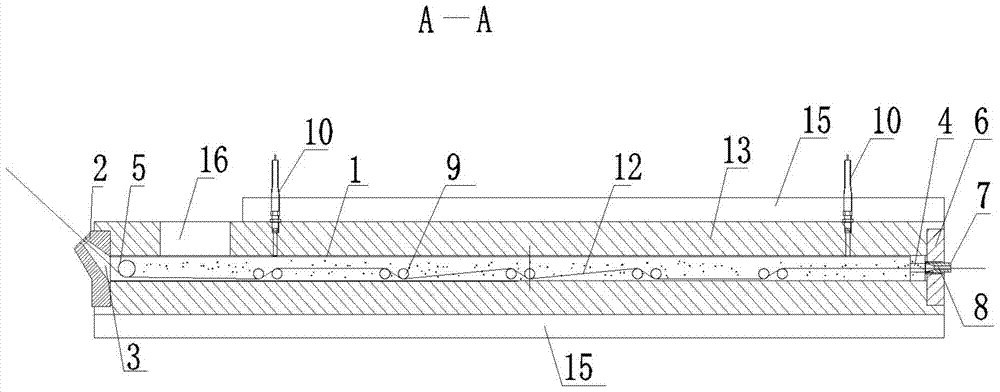

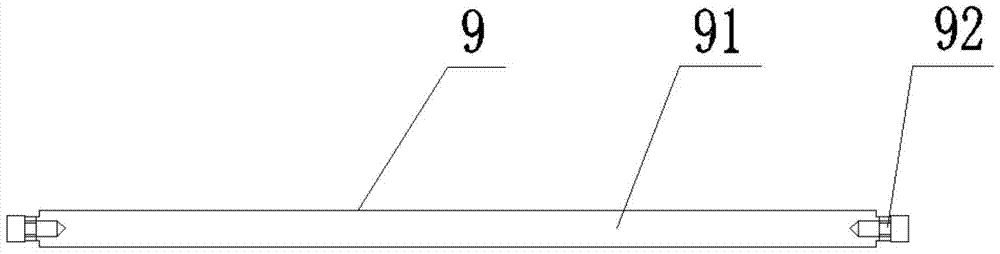

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 5 The glass fiber dispersing and guiding device shown includes a rectangular housing 13 and a frame 1 inside the housing. There is a melt inlet 16 above the housing 13, and the melt inlet 16 is used for installing a melt channel device. The housing 13 is similar to the shape of the matchbox outer box, and has four surfaces and two cavity openings 14. The internal space surrounded by the four surfaces is a dipping pool, and the frame 1 can be inserted into the dipping pool from the cavity opening; the frame 1 It is a combined frame, each part of which is detachable, which is convenient for replacing or cleaning the parts installed in the frame 1. A front baffle 2 is installed on one side of the frame 1, and a plurality of glass fiber inlets 3 are evenly opened on the front baffle 2, and the multiple glass fiber inlets 3 are on the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com