Method for comprehensively recovering cyanide-containing wastewater

A technology for cyanide wastewater and wastewater is applied in the field of comprehensive recovery of cyanide-containing wastewater, which can solve problems such as unreasonable methods for cyanide-containing wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

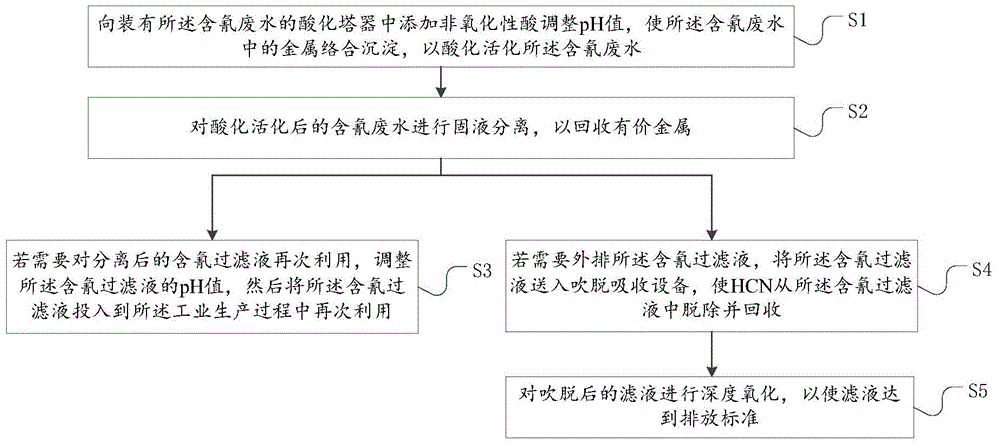

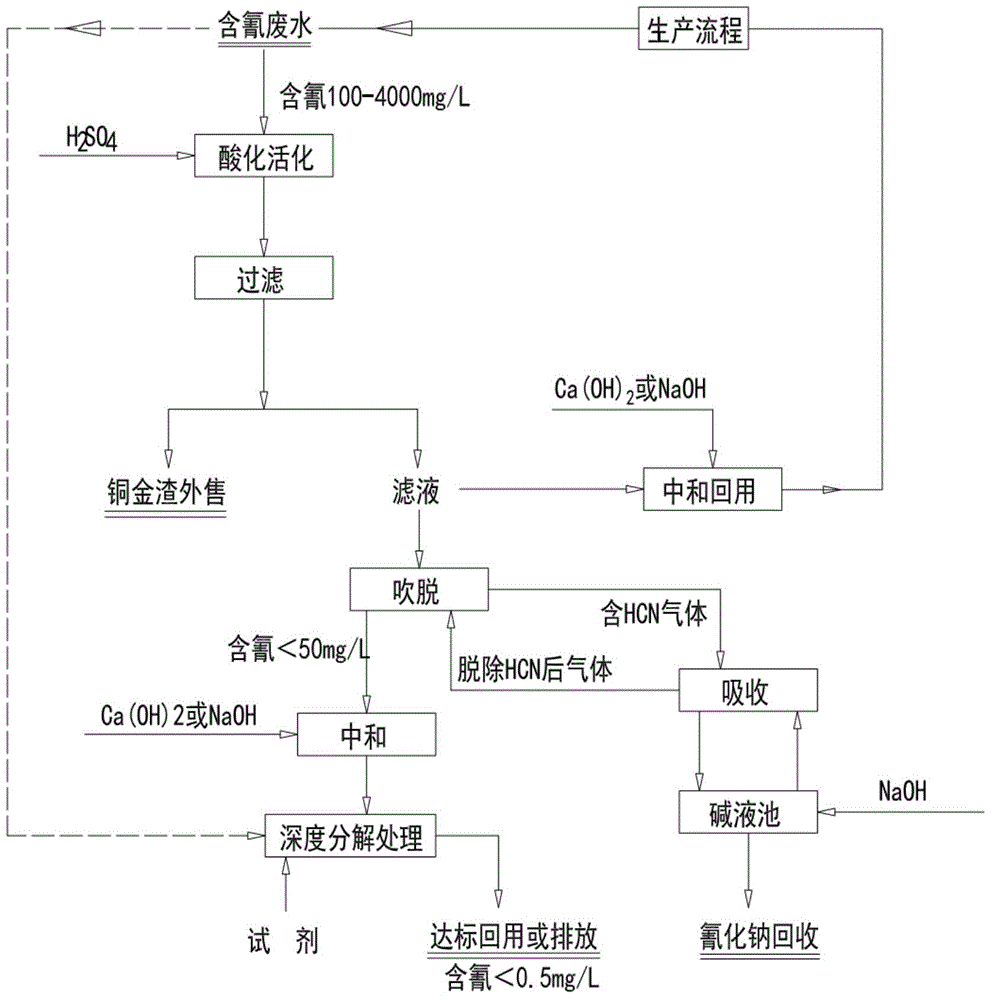

[0025] In order to not only improve the recovery rate of cyanide, but also realize the up-to-standard discharge of cyanide ions in wastewater, the present invention provides a method for comprehensive recovery of cyanide-containing wastewater. The process technology includes four parts: wastewater acidification activation, solid-liquid separation and comprehensive Recovery, stripping-absorption of acidizing liquid, deep oxidation treatment of stripping liquid. Specifically, the activation of wastewater acidification is mainly to add non-oxidizing acid to the acidification tower containing the cyanide-containing wastewater to adjust the pH value. The solid-liquid separation is for the recovery of valuable metals, and the solid-liquid separation of the cyanide-containing wastewater after acidification. During comprehensive recovery, the pH value of the cyanide-containing filtrate is adjusted, and then the cyanide-containing filtrate is put into the industrial production process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com