A kind of waterproof inorganic dry powder real stone paint

A technology of inorganic dry powder and real stone paint, which is applied in the field of building decoration materials, can solve the problems of dry powder coatings being easy to return to alkali and whitening, and achieve the effects of convenient transportation and storage, large elongation rate, and acid and alkali resistance of elongation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

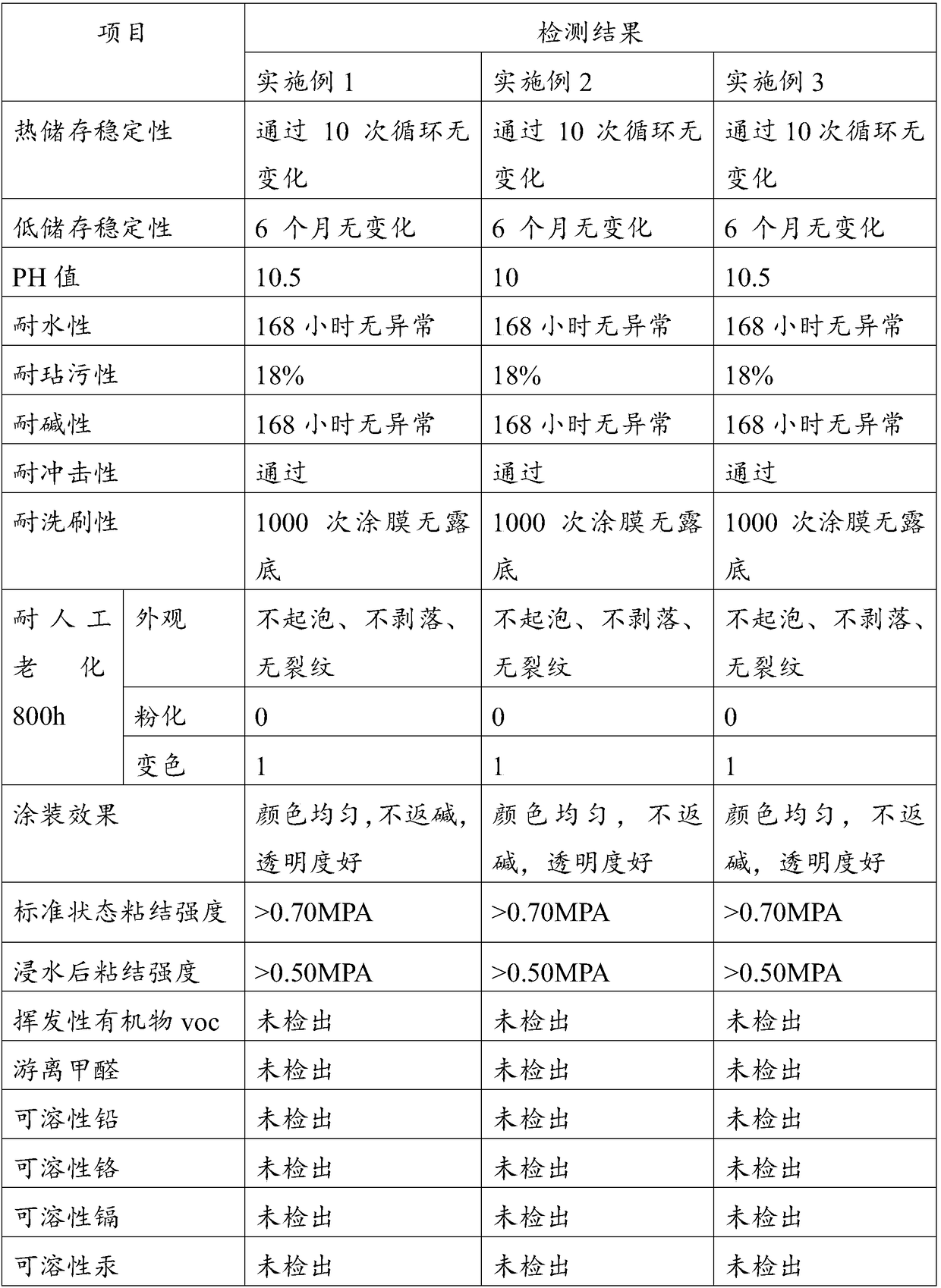

Examples

Embodiment 1

[0038] A waterproof inorganic dry powder real stone paint, the real stone paint is composed of the following components in parts by weight: 0.2 parts of wetting powder, 0.2 parts of film-forming aids, 0.2 parts of silane coupling agent, 10 parts of 60-mesh marble particles, 20 parts of granule 70 mesh, 40 parts of marble particle 80 mesh, 0.2 part of cellulose ether, 1 part of inorganic bentonite, 1 part of fumed silica, 2 parts of zinc oxide, 5 parts of latex powder, 0.25 part of ash calcium powder, methyl silicon 0.25 parts of potassium phosphate, 0.25 parts of sodium methyl silicate, wherein the cellulose ether is composed of methyl cellulose, hydroxyethyl cellulose, and hydroxypropyl cellulose, the fumed silica is more than 1000 mesh, and the content of ash calcium powder is The water content is less than 0.1%, the fineness is more than 800 mesh, and the marble particles include quartz sand, snowflake white, white marble, and natural colored sand.

[0039] The above formul...

Embodiment 2

[0046] A waterproof inorganic dry powder real stone paint, said real stone paint is composed of the following components in parts by weight: 0.4 part of wetting powder, 0.5 part of film-forming aid powder, 0.5 part of silane coupling agent, 1 part of titanium dioxide, marble particles 15 parts of 60 mesh, 30 parts of marble particle 70 mesh, 60 parts of marble particle 80 mesh, 0.4 part of cellulose ether, 2 parts of inorganic bentonite, 2 parts of fumed silica, 4 parts of zinc oxide, 5 parts of inorganic pigment, 5 parts of latex powder 0.25 parts, 0.25 parts of ash calcium powder, 0.25 parts of potassium methyl silicate, and 0.25 parts of sodium methyl silicate.

[0047] The above is the formula for adjusting the color of non-natural stone grains, wherein the methyl silicate is composed of potassium methyl silicate and sodium methyl silicate in a ratio of 1:1, and the cellulose ether is composed of methyl cellulose, hydroxyethyl cellulose , hydroxypropyl cellulose, fumed sil...

Embodiment 3

[0054] A waterproof inorganic dry powder real stone paint, the real stone paint is composed of the following components in parts by weight: 0.3 parts of wetting powder, 0.3 parts of film-forming auxiliary powder, 0.3 parts of silane coupling agent, 0.5 parts of titanium dioxide, marble particles 12 parts of 60 mesh, 25 parts of marble particle 70 mesh, 50 parts of marble particle 80 mesh, 0.3 part of cellulose ether, 1.5 parts of inorganic bentonite, 1.5 parts of fumed silica, 3 parts of zinc oxide, 2.5 parts of inorganic pigment, 5 parts of latex powder 0.25 parts of potassium methyl silicate, 0.25 parts of sodium methyl silicate, 0.25 parts of lime calcium powder,

[0055] The method for preparing above-mentioned waterproof inorganic dry powder genuine stone paint, it may further comprise the steps:

[0056] 1) Add 0.5 parts of titanium dioxide, 12 parts of 60-mesh marble particles, 25 parts of 70-mesh marble particles, 50 parts of 80-mesh marble particles, and 3 parts of zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com