A kind of high durability concrete and preparation method thereof

A concrete and durable technology, which is applied in the field of high-durability concrete and its preparation, can solve the problems of poor compressive strength and flexural strength of photovoltaic pavement, poor concrete strength, and short service life, so as to improve photoelectric conversion efficiency and compressive strength High, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] As a kind of preferred preparation method, the preparation method of described a kind of antibacterial concrete comprises the steps:

[0033] S1. Weigh all the raw materials according to the weight percentage, mix the weighed epoxy resin, curing agent, polyethylene glycol, and ethanolamine, heat to 150-180°C, and stir to make the epoxy resin, curing agent, Polyethylene glycol and ethanolamine are completely dissolved to form a transparent solution to obtain a resin compound;

[0034] S2. Put the titanium dioxide in the weight percentage into the resin glue and stir for 10-30min, mix evenly to make resin glue mortar;

[0035] S3. mixing the glass particles in the weight percentage into the resin mortar and stirring for 30-60min to obtain transparent concrete;

[0036] S4. The transparent concrete is introduced into a mold for compaction, placed at room temperature for curing and molding, and the durable concrete specimen is obtained after demoulding.

[0037] The prese...

Embodiment 1

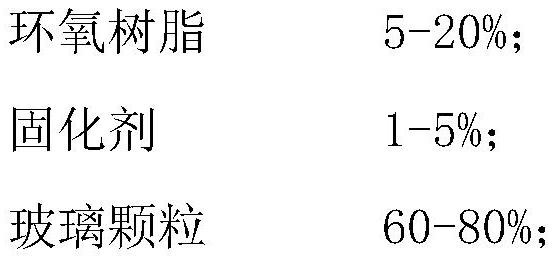

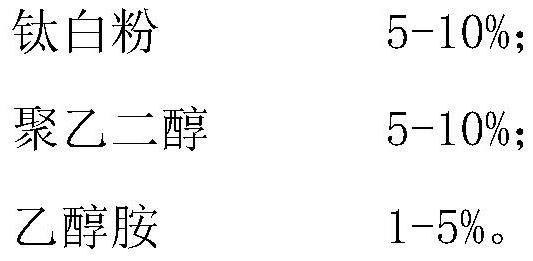

[0039] A highly durable concrete made from the following components by weight percentage:

[0040]

[0041] The epoxy resin is formed by mixing epoxy resin AFG-90 and epoxy resin TDE-85 in a weight ratio of 1:1; the curing agent is cyclohexanone peroxide; the polyethylene glycol is preferably polyethylene glycol Alcohol 20000 and polyethylene glycol 400 are mixed in a weight ratio of 1:0.1; the ethanolamine is preferably prepared by mixing diethanolamine and triethanolamine in a weight ratio of 1:0.1.

[0042] The preparation method of durable concrete described in the present embodiment comprises the steps:

[0043] S1. Weigh all the raw materials according to the weight percentage, mix the weighed epoxy resin, curing agent, polyethylene glycol, and ethanolamine, heat to 150°C, and stir to make the epoxy resin, curing agent, polyethylene glycol Glycol and ethanolamine are completely dissolved to form a transparent solution to obtain a resin compound;

[0044] S2. Put the t...

Embodiment 2

[0048] This embodiment provides a high-durability concrete. Compared with Embodiment 1, the difference is that it is made of the following components in weight percentage: 10% epoxy resin; 5% curing agent; 70% glass particles; titanium dioxide 5%; polyethylene glycol 5%; ethanolamine 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com