Heat insulation paint and application thereof

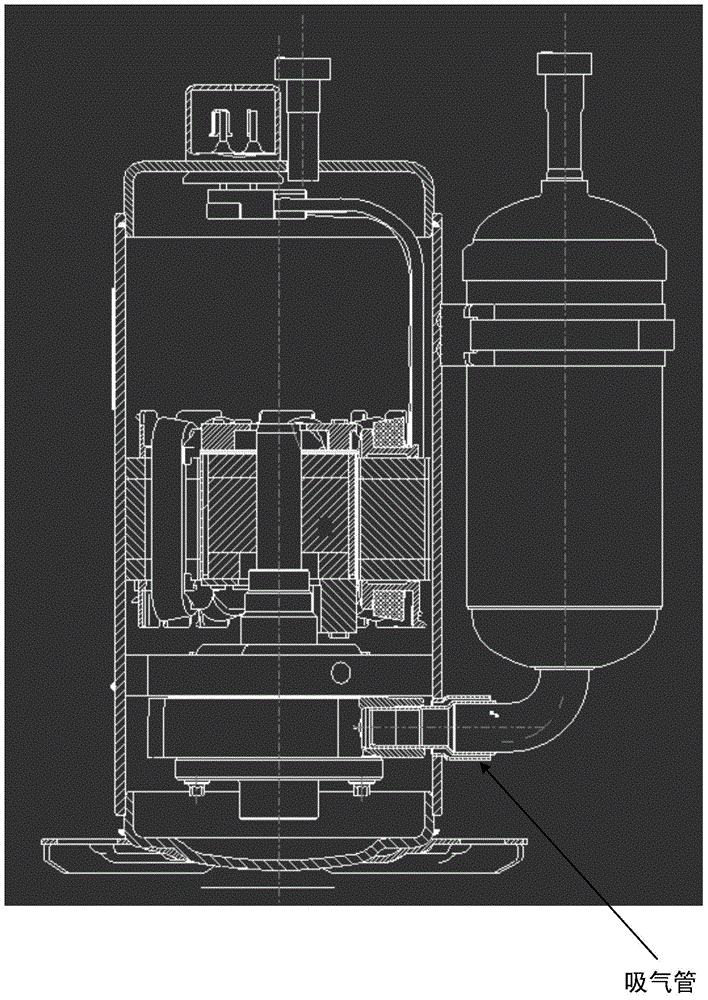

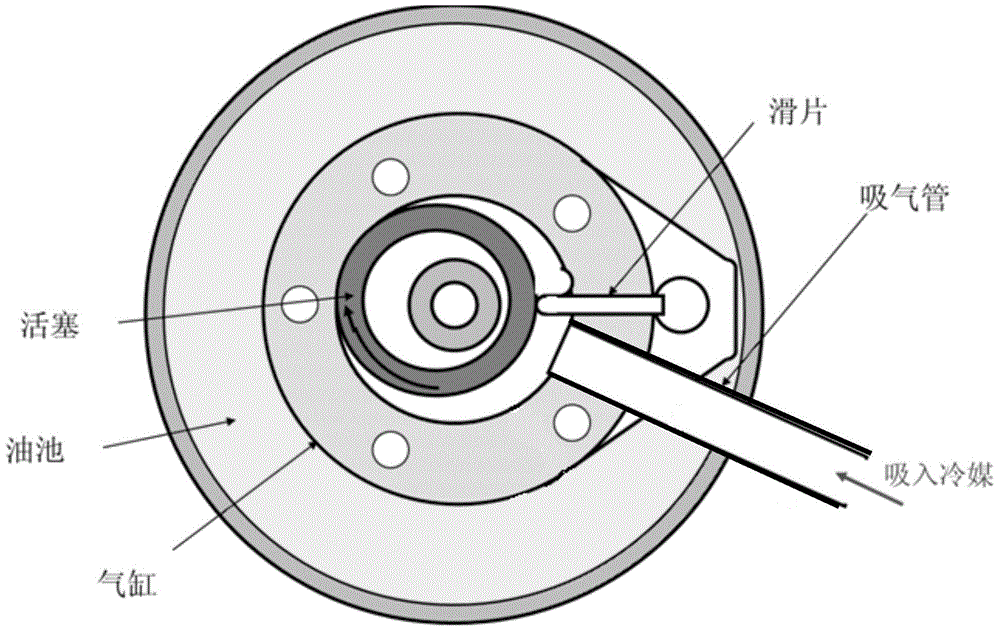

A technology of thermal insulation coating and thermal insulation coating, which is applied in the fields of compressor, thermal insulation coating and thermal insulation coating, can solve the problems such as the compressor needs to be deepened, the suction temperature is high, and the refrigeration efficiency of the compressor is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

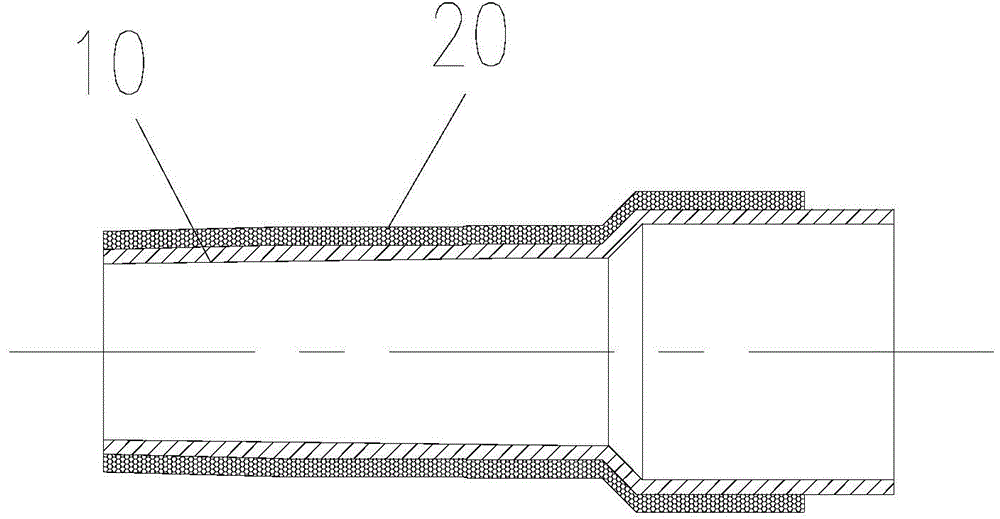

Embodiment 1

[0035] The hollow microspheres (selected from Al 2 o 3 , ZrO 2 , SiO 2 At least one of the above) is mixed with fluorosilicon-modified acrylic emulsion, and evenly stirred by a mechanical stirrer to obtain a heat-insulating coating in which the hollow microspheres are 85% by weight, wherein the average size of the hollow microspheres is 40 μm. Inject the obtained thermal insulation coating into the spraying system, and evenly coat the outer surface of the suction pipe by spraying to form a layer of porous sealing coating that takes into account both thermal insulation and toughness. The film thickness is 0.1mm, and the obtained The suction pipe is assembled to the compressor and the cooling capacity test is carried out. The results show that at 80 °C, the inner wall of the copper tube can be reduced by 6 °C, and the cooling capacity can be increased by 1.7%, which effectively improves the cooling efficiency.

Embodiment 2

[0037] The hollow microspheres (selected from Al 2 o 3 , ZrO 2 , SiO 2 At least one of the above) is mixed with fluorosilicon-modified acrylic emulsion, and stirred evenly by a mechanical stirrer to obtain a heat-insulating coating in which the hollow microspheres are 50% by weight, wherein the average size of the hollow microspheres is 20 μm. Inject the obtained thermal insulation coating into the spraying system, and evenly coat the inner surface of the suction pipe by spraying to form a layer of porous sealing coating that takes into account both thermal insulation and toughness. The film thickness is 0.5mm, and the obtained The suction pipe was assembled on the compressor and carried out the cooling capacity test, obtained the result similar to that of Example 1.

Embodiment 3

[0039] The hollow microspheres (selected from Al 2 o 3 , ZrO 2 , SiO 2 At least one of the above) is mixed with fluorosilicon-modified acrylic emulsion, and evenly stirred by a mechanical stirrer to obtain a heat-insulating coating in which the hollow microspheres are 90% by weight, wherein the average size of the hollow microspheres is 80 μm. Inject the obtained thermal insulation coating into the spraying system, and evenly coat the outer surface of the suction pipe by spraying to form a layer of porous airtight coating that takes into account both thermal insulation and toughness. The film thickness is 1 mm, and the obtained The suction pipe was assembled on the compressor and subjected to a cooling capacity test, and the results similar to those in Example 1 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com