Hydraulic power unit system capable of automatically controlling and distributing oil quantity and jacking and falling method of hydraulic power unit system

A technology of linkage control system and hydraulic pump station, applied in the field of hydraulic jacking, can solve the problems of limited precise control of jack displacement and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

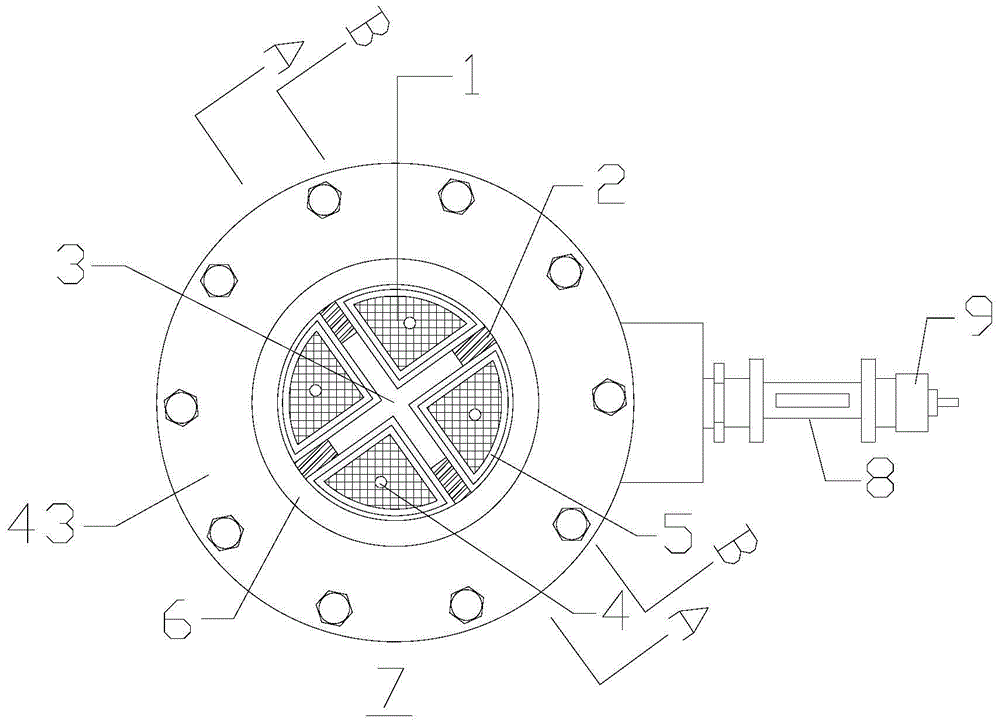

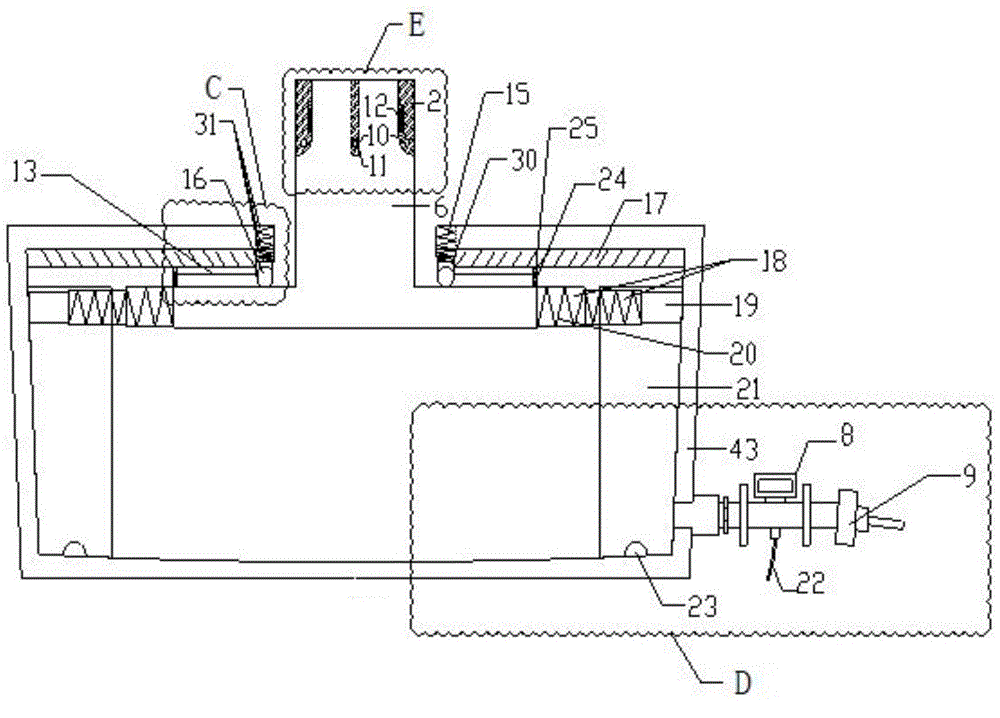

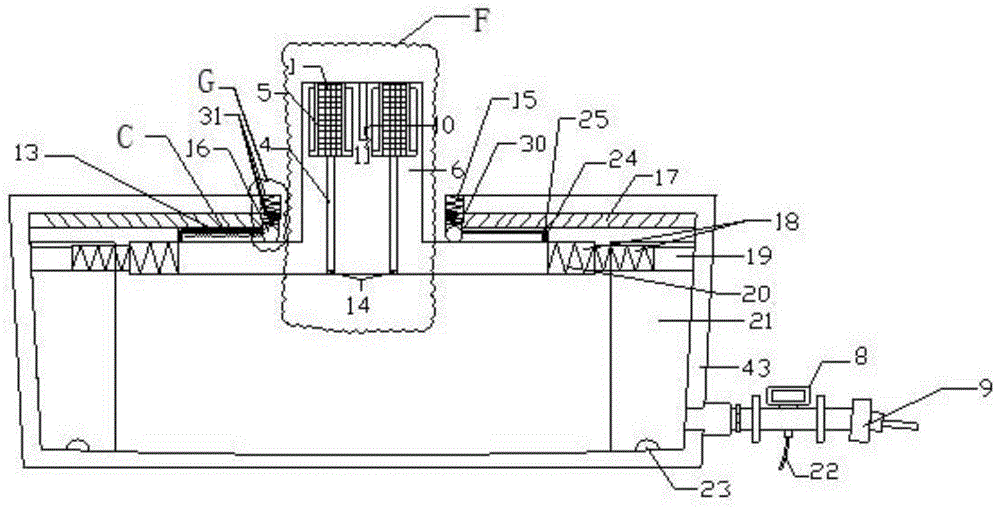

[0050] See attached Figure 1-19 As shown, this embodiment provides a three-stage double-acting self-fitting hydraulic jack 7 and a hydraulic pump station system 44 for automatically controlling and distributing oil. The external structure of each three-stage double-acting self-fitting hydraulic jack 7 consists of a first-stage piston cylinder 6, a second-stage piston cylinder 5, a third-stage piston cylinder 1, an external oil cylinder 43, and a digital flowmeter 8 (equipped with Digital flowmeter data line 22) and oil cylinder oil inlet 9 are composed together, such as figure 1 with Figure 15 As shown, the second stage piston cylinder 5 and the third stage piston cylinder 1 are arranged inside the first stage piston cylinder 6. The oil volume automatic control and distribution hydraulic pump station system 44 is configured by installing multiple three-stage double-acting self-fitting hydraulic jacks 7 of the same type and specifications between the bridge girder body 35 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com