A device and method for improving permeability and drainage of gas in soft coal seam recovery working face

A technology for mining working face and gas extraction, which is applied in the field of devices for improving permeability and draining gas at working face of soft coal seam, and can solve the problem of easy occurrence of injection holes, smashed holes, blocked holes, stuck drilling, and has not been widely popularized. , the problem of high production cost per ton of coal, to achieve the effect of improving single-hole drainage capacity, increasing desorption surface area, and avoiding engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

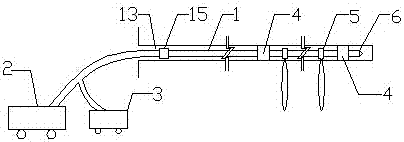

[0035] For a single coal seam with a buried depth of 623 m and an average thickness of 4.8 m, the inclination angle of coal seam 12 is 6°-12°, with an average of about 8°. Coal is soft and mostly in the form of fragments. The relative gas content of coal seam 12 is 27 m³ / t, and the gas pressure is 1.8 MPa. The immediate roof of coal seam 12 is sandstone, with a thickness of 7.5-12.8 m, with an average thickness of 9.1 m; the old roof is fine sandstone, with a thickness of 4-22.4 m, with an average thickness of 14.9 m; the floor of coal seam 12 is carbonaceous mudstone or mudstone, with a thickness of 3.9-27.6 m , with an average thickness of 16.2 m. The integrity of the roof strata is good.

[0036] Design the location of the drilling site 11, the distance between the drill hole 13 and the coal seam 12, and the length of the drill hole 13 according to the spatial position of the transport entryway 14 and the layer relationship of the coal seam 12, the length of the working f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com