Direct-acting type axial flow electromagnetic valve

A solenoid valve and direct-acting technology, which is applied in the field of solenoid valves, can solve the problems that restrict the wide use of direct-acting solenoid valves, the difficulty of current flow in aerospace flight systems, and the increase in coil heat dissipation requirements, and achieve compact structure, large circulation area, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

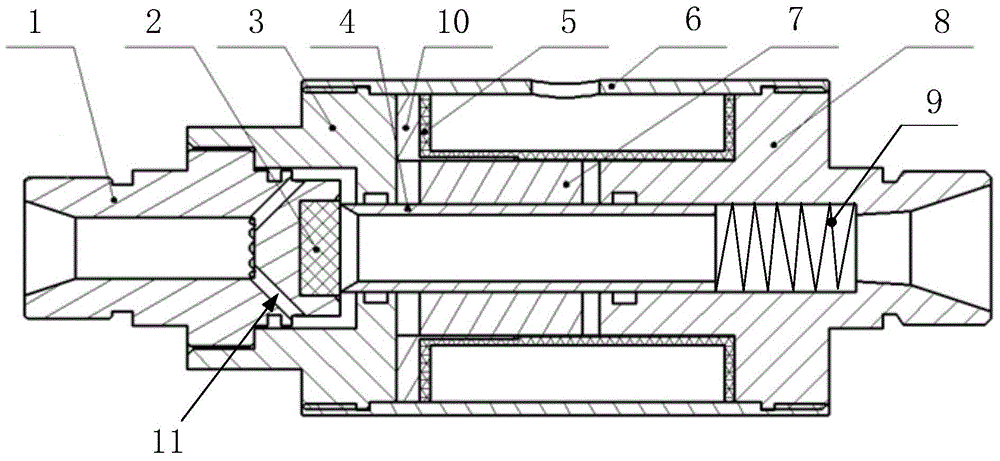

[0024] The direct-acting axial flow electromagnetic valve of the present invention includes an inlet nozzle 1, a valve core gasket 2, a gland 3, a valve core 4, a coil frame 5, a casing 6, a moving armature 7, a stationary yoke 8 and a spring 9, such as figure 1 shown.

[0025] The inlet nozzle 1 is a cylindrical structure made of stainless steel, with an expansion opening at the front end. The gland 3 is a cylindrical structure, coaxially arranged with the inlet nozzle 1, and the front end is threadedly connected to the rear end of the rear outer wall of the inlet nozzle 1, and the space is sealed by a sealing ring; through the circumferential shoulder of the inner wall of the gland 3 and the outer wall of the inlet nozzle 1 The positioning steps designed in the circumferential direction cooperate to realize the positioning of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com