Sound-absorbing structure of porous foam silicon carbide sound-absorbing material

A foamed silicon carbide and porous silicon carbide technology, which is applied to sound-producing instruments, instruments, etc., can solve the problems of poor sound-absorbing effect of porous materials, and achieve the effects of improving sound-absorbing performance, improving low-frequency sound-absorbing effect, and good sound-absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

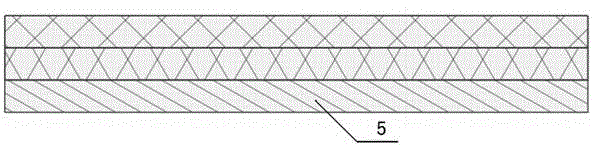

[0029] Such as figure 1 As shown, two or more layers of foamed silicon carbide 5 with different porosity, pore size, and thickness are the same or different for bonding combination (three layers in this embodiment) to form a sound-absorbing structure of porous foamed silicon carbide sound-absorbing material.

[0030] The porous silicon carbide foam used in the sound-absorbing structure has a pore structure of a three-dimensional interconnected foam structure with a pore size between 0.3 mm and 5 mm and a porosity between 70 and 90%.

Embodiment 2

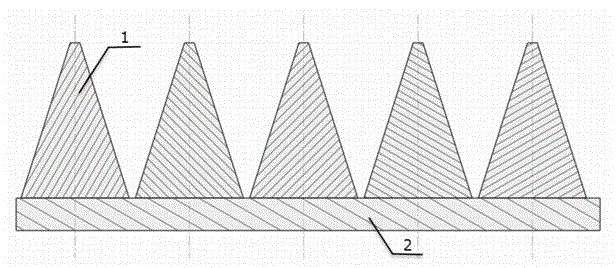

[0032] Such as figure 2 As shown, taking advantage of the machinable characteristics of foamed silicon carbide materials, the structure of sound-absorbing wedge 1 is superimposed on the base 2 of foamed silicon carbide 5, and the base 2 and wedge 1 are bonded and compounded to form a porous foamed silicon carbide sound-absorbing material sound-absorbing structure. Wherein, the height of the wedges 1 is less than 50mm, and the wedges 1 are arranged in parallel.

[0033] The porous silicon carbide foam used in the sound-absorbing structure has a pore structure of a three-dimensional interconnected foam structure with a pore size between 0.3 mm and 5 mm and a porosity between 70 and 90%.

Embodiment 3

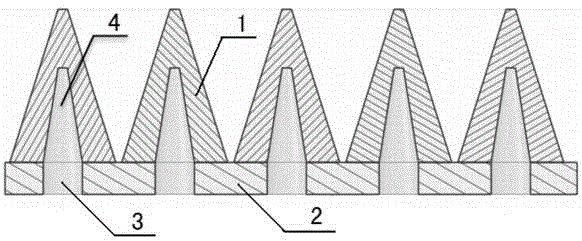

[0035] Such as image 3 As shown, taking advantage of the machinable characteristics of foamed silicon carbide material, the perforation 3 can be processed on the base 2 of the foamed silicon carbide 5, and the structure of the sound-absorbing wedge 1 is superimposed on the base 2 of the foamed silicon carbide, and the base 2 and the wedge 1 Bonding and compounding to form a sound-absorbing structure of porous foam silicon carbide sound-absorbing materials. Wherein, the hole diameter of the perforation is less than 10mm, the height of the wedges 1 is less than 50mm, the wedges 1 are arranged in parallel, and the bottom of the wedges 1 is provided with a wedge-shaped hole 4 to form a hollow structure. The wedge-shaped hole 4 corresponds to the perforation 3 of the base 2 , and the size of the wedge-shaped hole 4 and the perforation 3 correspond to each other.

[0036] The porous silicon carbide foam used in the sound-absorbing structure has a pore structure of a three-dimensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com