Modified 5a molecular sieve for removing a small amount of n-hexane in isohexane and its regeneration method

A technology of molecular sieve and isohexane, which is applied in the field of regeneration of modified 5A molecular sieve, which can solve the problems of clogging molecular sieve, reducing the desorption effect, affecting the continuous operation of molecular sieve to n-hexane, etc., so as to avoid the effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The modified 5A molecular sieve used in the present invention is a 5A molecular sieve obtained by removing non-skeleton aluminum with oxalic acid, which means that the modified 5A molecular sieve is obtained by soaking and dealuminating the 5A molecular sieve to be modified with an ethanol solution of oxalic acid.

[0024] Its modification method comprises the following steps:

[0025] Soak 120 g of molecular sieves in 180 mL of oxalic acid ethanol solution with a concentration of 0.38 mol / L for 2 h to remove non-framework aluminum. The dealuminated molecular sieve was washed with water, activated at 500° C. for 4 hours, and then cooled in a desiccator to obtain a modified 5A molecular sieve.

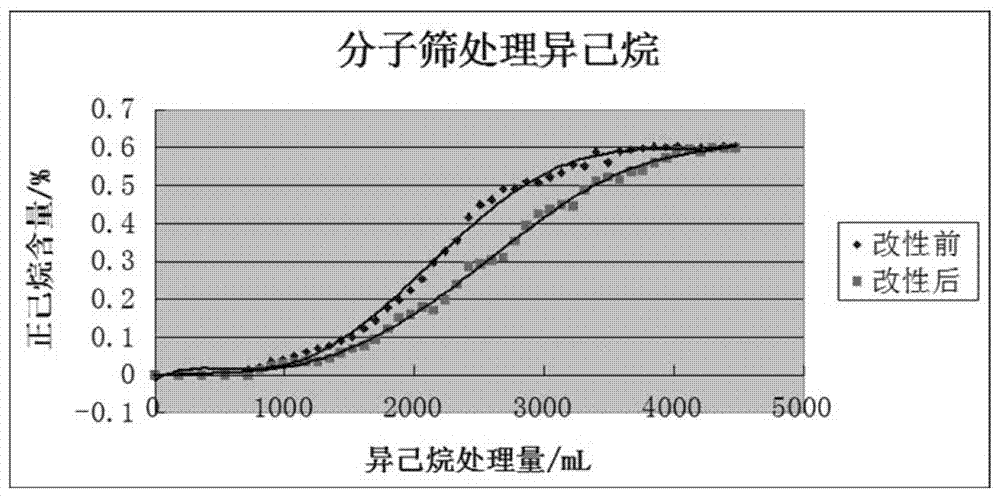

[0026] Such as figure 1 As shown, the above-mentioned modified 5A molecular sieve is used to adsorb a small amount of n-hexane in isohexane, and the adsorption effect of the 5A molecular sieve before modification is compared. It can be clearly seen that before modification and ...

Embodiment 2

[0031] The modified 5A molecular sieve used in the present invention is a 5A molecular sieve obtained by removing non-skeleton aluminum with oxalic acid, which means that the modified 5A molecular sieve is obtained by soaking and dealuminating the 5A molecular sieve to be modified with an ethanol solution of oxalic acid.

[0032] The modification method includes the following steps: soak 120 g of molecular sieves in 180 mL of oxalic acid ethanol solution with a concentration of 0.19 mol / L for 2 hours to remove non-skeleton aluminum. After the dealuminated molecular sieves were washed with water, they were activated at 500°C for 4 hours, and then cooled in a desiccator.

[0033] Use the above-mentioned modified 5A molecular sieve to adsorb a small amount of n-hexane in isohexane.

[0034] After the molecular sieve absorbs n-hexane, it will be regenerated. First pass water vapor at 110°C into the molecular sieve for 1 hour to replace the n-hexane in its micropores, and then pur...

Embodiment 3

[0036] The modified 5A molecular sieve used in the present invention is the 5A molecular sieve obtained by removing non-framework aluminum from oxalic acid. The modification method includes the following steps: soak 120 g of molecular sieves in 180 mL of oxalic acid ethanol solution with a concentration of 0.5 mol / L for 2 hours to remove non-skeleton aluminum. After the dealuminated molecular sieves were washed with water, they were activated at 500°C for 4 hours, and then cooled in a desiccator.

[0037] Use the above-mentioned modified 5A molecular sieve to adsorb a small amount of n-hexane in isohexane.

[0038] After the molecular sieve absorbs n-hexane, it will be regenerated. First pass 110°C water vapor into the molecular sieve for 3 hours to replace the n-hexane in its micropores, and then purge with nitrogen gas with a flow rate of 2L / min (20°C, 0.35MPa) at 250°C for 3 hours, and the entire regeneration process is completed. The adsorption of n-hexane can then be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com