Pull-cord encoder based calibration method of industrial robot

An industrial robot and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problem that the absolute positioning accuracy of the robot cannot meet the requirements of offline programming, and achieve the effect of easy implementation, compensation for loss, and improvement of absolute positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

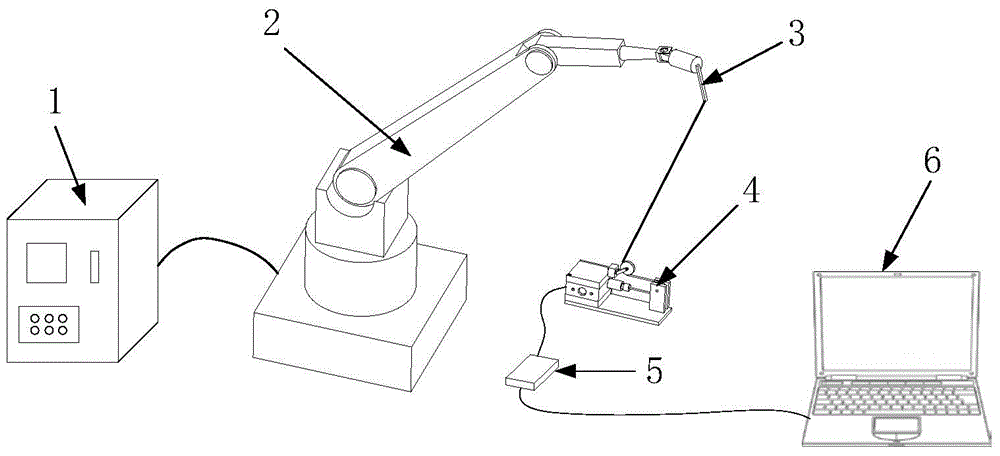

[0028] Such as figure 1 shown. In the calibration algorithm of industrial robots based on wire draw encoders, the calibration system consists of a robot controller 1, a robot to be calibrated 2, a connecting rod 3, a wire draw encoder 4, a data acquisition card 5 and a computer 6. The industrial robot 1 whose basic process is to be calibrated is installed at a fixed position in the workshop, and its coordinate system is related to the earth coordinate system. The end flange of the robot is equipped with a connecting rod 3 matching the pull-wire encoder, and the pull-wire encoder 4 Try to place it in the middle of the working range of the robot. Under this principle, the position of the pull-wire encoder 4 can be arbitrary, and the robot 2 to be calibrated moves to different positions in space under the drive of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com