Fabric paint spray for fabric painting and fabric painting technology

An aerosol and textile technology, applied in the field of textiles, can solve problems that have never occurred before, such as high cost and great influence of temperature changes, and achieve the effect of reducing the burden on enterprises, saving operating costs, and enhancing the promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

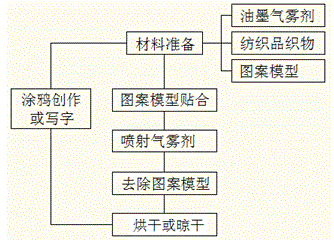

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The weight ratio of the ink aerosol is as follows (based on the total weight of 100g aerosol ratio):

[0029] Organic pigment 8g;

[0030] Acrylic resin or emulsion 10g;

[0031] Leveling agent 7g;

[0032] 15g deionized water;

[0033] Ethanol 30g;

[0034] Dimethyl ether 30g; Described dimethyl ether is propellant.

[0035] Before using the aerosol with this ratio, it needs to be shaken to make the liquid in the aerosol bottle mix evenly, and the nozzle of the aerosol bottle is opened. Dimethyl ether is a homologue of ether, but it is different from ether used as an anesthetic. It is toxic Very low; can dissolve various chemical substances; because of its easy compression, condensation, gasification and miscibility with many polar or non-polar solvents, it has a good effect as a propellant. The pressure of the propellant is generally between 0.35Mpa and 0.65Mpa. The nozzle seat of the aerosol bottle uses a publication number of CN 203598987U (such ...

Embodiment 2

[0046] Embodiment 2: The proportion of the aerosol of the present invention also includes the following components by weight percentage (the total weight is 100g):

[0047] Organic pigment 5g;

[0048] Acrylic resin or emulsion 14g;

[0049] Leveling agent 4g;

[0050] Deionized water 10g;

[0051] Ethanol 40g;

[0052] Dimethyl ether 27g; Described dimethyl ether is propellant.

[0053] The above-mentioned aerosol proportion accounts for 27% of the total weight, and has a strong propulsion effect. Regardless of whether the nozzle uses a diffuse nozzle or a linear nozzle, a good spray effect can be achieved.

[0054] The aerosol of the present invention performs DIY (do it yourself) on textiles, making textiles more unique. Using the textile ink aerosol (Fabric paint spray) of the present invention, its dimethyl ether is used as a propellant, can effectively strengthen the propulsion effect of the ink, and make the textile painting uniform, beautiful and durable. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com