Two-phase flow liquid distributor

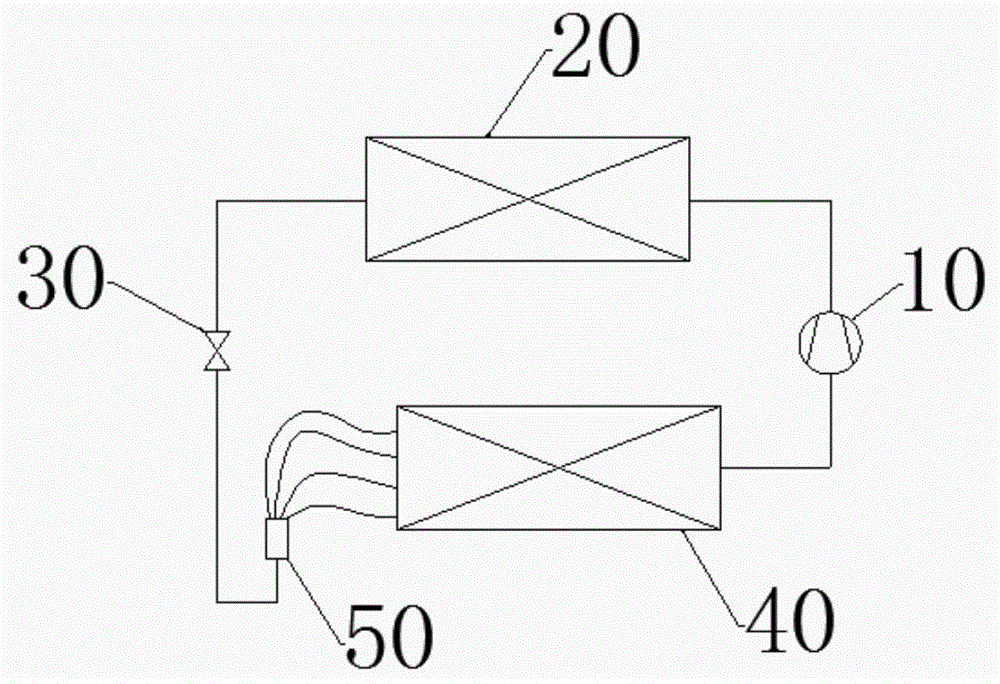

A liquid separator and phase flow technology, applied in the field of compressors, can solve the problems of large drop in liquid separation performance, complex process flow, easy welding and blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

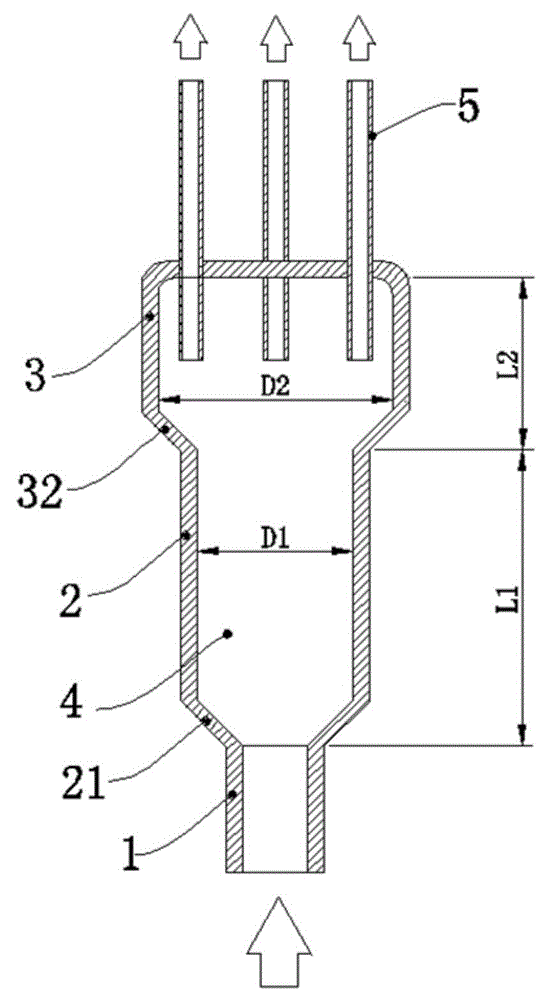

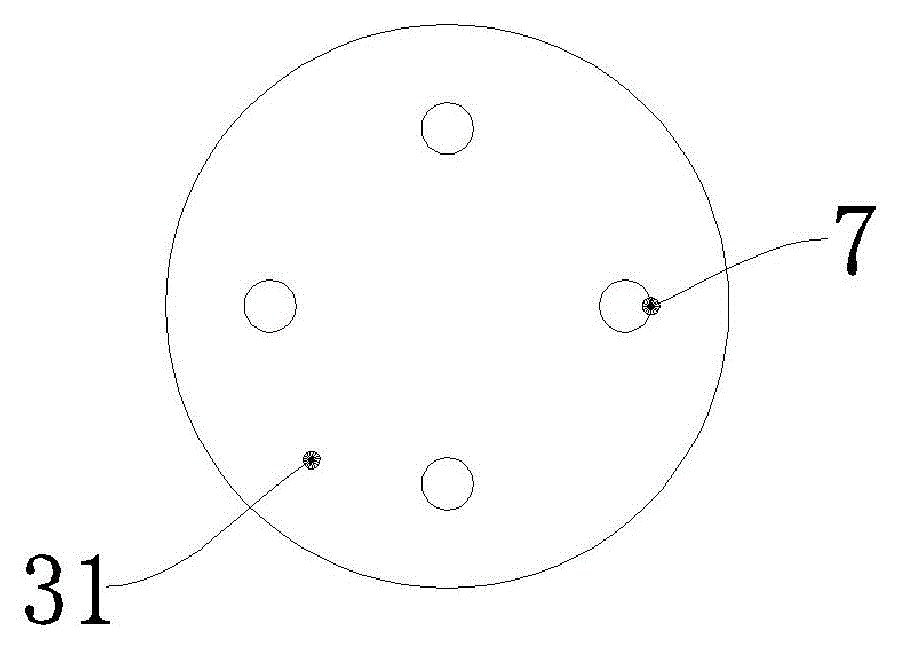

[0024] Such as figure 1 and figure 2 As shown, this embodiment includes: an inlet pipe 1, a front cylinder body 2, a rear cylinder body 3 and a branch pipe 5, wherein: the inlet pipe 1, the front cylinder body 2 and the rear cylinder body 3 are connected in sequence and the cross sections are Circular structure, the inside of the front cylinder 2 and the rear cylinder 3 forms a hollow chamber 4, and the top 31 of the rear cylinder 3 is evenly spaced with a number of liquid separation holes 5 communicating with the hollow chamber 4, and each liquid separation hole 5 is provided with a branch pipe 7;

[0025] The inner diameters of the inlet pipe 1, the front cylinder body 2 and the rear cylinder body 3 increase sequentially.

[0026] The relationship between the length L1 and inner diameter D1 of the front cylinder 2 and the length L2 and inner diameter D2 of the rear cylinder 3 satisfies: 1.5 ≤ ( L ...

Embodiment 2

[0039] Such as Figure 6 As shown, the inside of the front cylinder body 2 is provided with a cylindrical built-in filter screen. The cross section of the built-in filter screen is trapezoidal, and its bottom edge is fixed on the groove structure provided inside the front cylinder body 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com