A system and method for calibrating electric spark ignition energy under high pressure

An ignition energy and calibration system technology, which is applied in the field of spark ignition energy calibration systems and methods under high pressure, can solve the problems of difficulty in quantitative research on the ignition characteristics of combustible premixed gas, inability to obtain the exact energy of the spark, and eliminate heat loss. Effects of interference, reduced heat loss, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

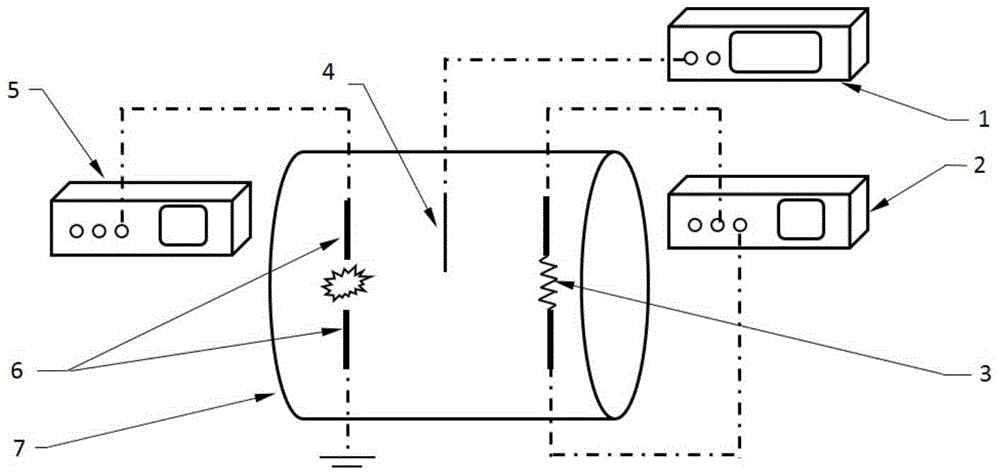

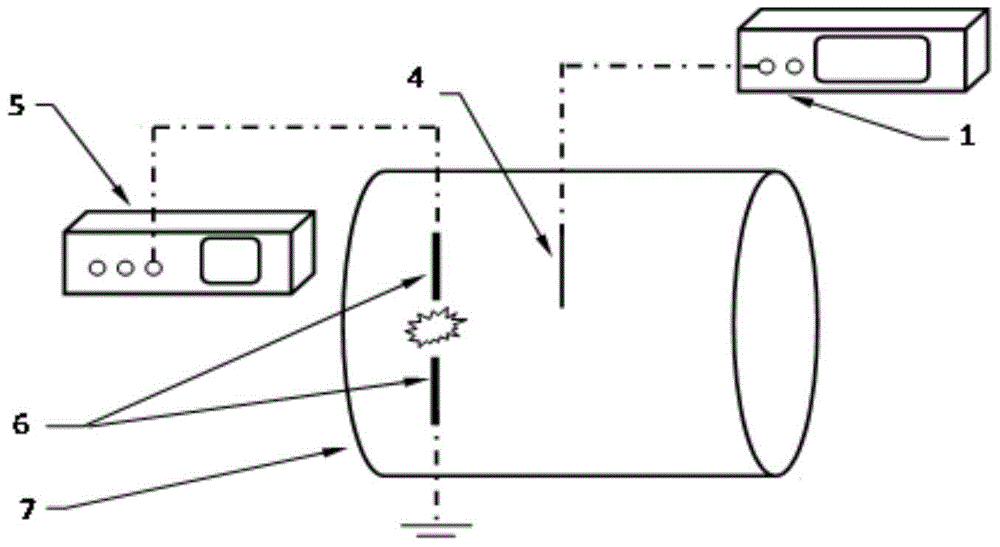

[0033] Specific implementation mode 1: When the electric spark electrode and the heating resistance wire are arranged symmetrically in the high-pressure adiabatic chamber,

[0034] Fill the adiabatic cavity with compressed air to make the pressure reach 10 atmospheres. Adjust the voltage of the high-voltage pulse ignition device to 60kV, and set the spark generation frequency to 10Hz (that is, 10 times per second). Record the reading of the sensitive thermocouple display meter T 1 =25°C, turn on the high-voltage pulse ignition device, start to generate constant frequency electric sparks, and start timing at the same time. Turn off the high-voltage pulse ignition device after timing for 100 seconds, and record the reading T of the thermocouple display meter 2 = 45°C.

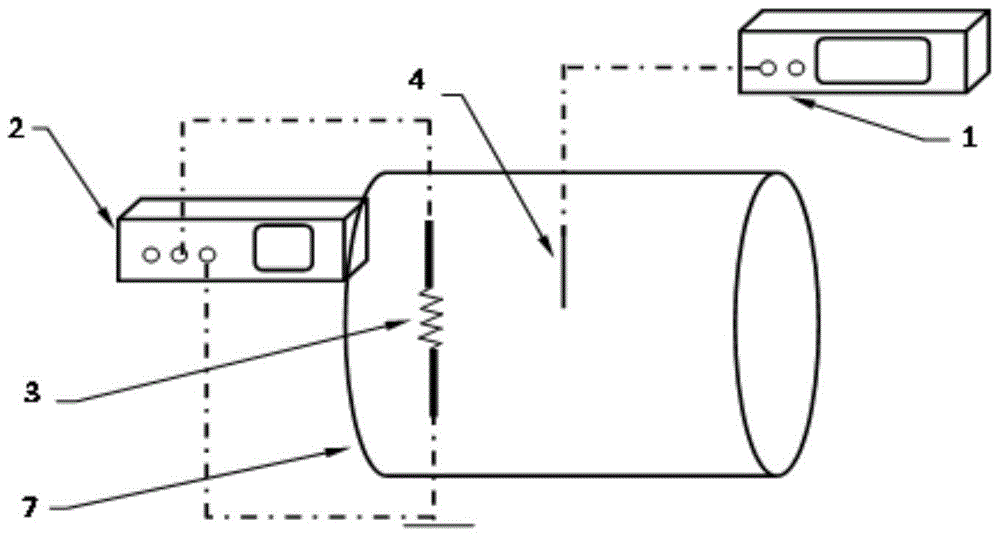

[0035] Wait until the cavity returns to normal temperature (the thermocouple reading is 25° C.), and then fill the adiabatic cavity with compressed air at a pressure of 10 atmospheres again. Set the controlle...

specific Embodiment approach 2

[0037] Specific implementation mode 2: When the electric spark electrode and the heating resistance wire are arranged alternately in the high-pressure heat-insulating cavity

[0038] Fill the adiabatic cavity with compressed air to make the pressure reach 10 atmospheres. Adjust the voltage of the high-voltage pulse ignition device to 60kV, and set the spark generation frequency to 10Hz (that is, 10 times per second). Record the reading of the sensitive thermocouple display meter T 1 =25°C, turn on the high-voltage pulse ignition device, start to generate constant frequency electric sparks, and start timing at the same time. Turn off the high-voltage pulse ignition device after timing for 100 seconds, and record the reading T of the thermocouple display meter 2 = 45°C.

[0039] Wait until the cavity returns to normal temperature (the thermocouple reading is 25°C), remove the spark electrode, put the resistance wire in the same position, and fill the adiabatic cavity with compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com