Sounder module

A technology of sound generator and module, applied in speaker screen, speaker transducer fixing, sensor and other directions, can solve the problems of intensified polarization of vibration system, large sound pressure release, asymmetric distribution of sound field, etc., to reduce harmonic distortion , Improve harmonic distortion, reduce the effect of system polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

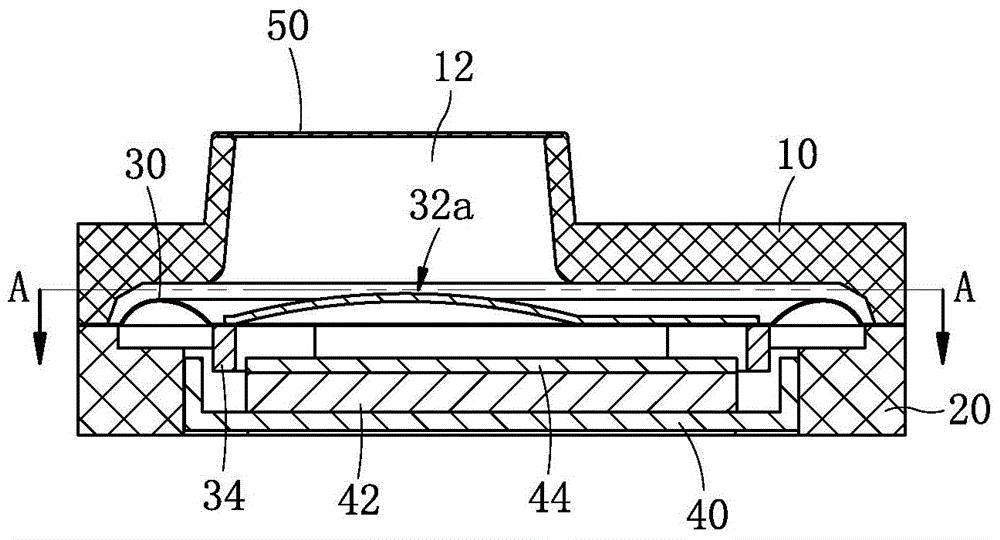

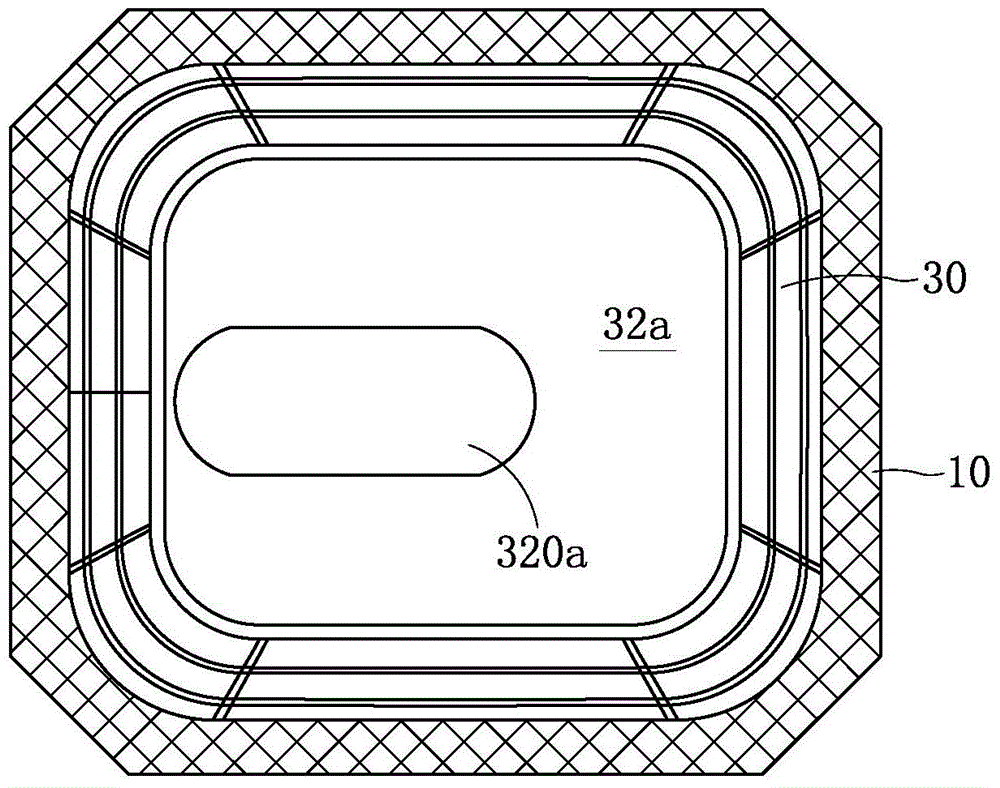

[0026] Such as figure 1 As shown, a sounder module includes a casing, and the casing is composed of an upper casing 10 and a lower casing 20 combined together, and a vibration system and a magnetic circuit system are accommodated in the space enclosed by the upper casing 10 and the lower casing 20 . The vibration system includes a diaphragm 30 whose edge is fixed between the upper case 10 and the lower case 20, a spherical top 32a is fixed in the middle of one side of the diaphragm 30 close to the upper case 10, and a voice coil is fixed on the other side of the diaphragm 30. 34. The magnetic circuit system includes a pot frame 40 fixed on the inner side of the lower shell 20, a magnet 42 and a washer 44 are fixed in the center of the inner side of the pot frame 40 in turn, and a magnetic gap is provided between the magnet 42, the washer 44 and the side wall of the pot frame 40 , the end of the voice coil 34 is located in the magnetic gap. The voice coil 34 reciprocates up ...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the difference is that:

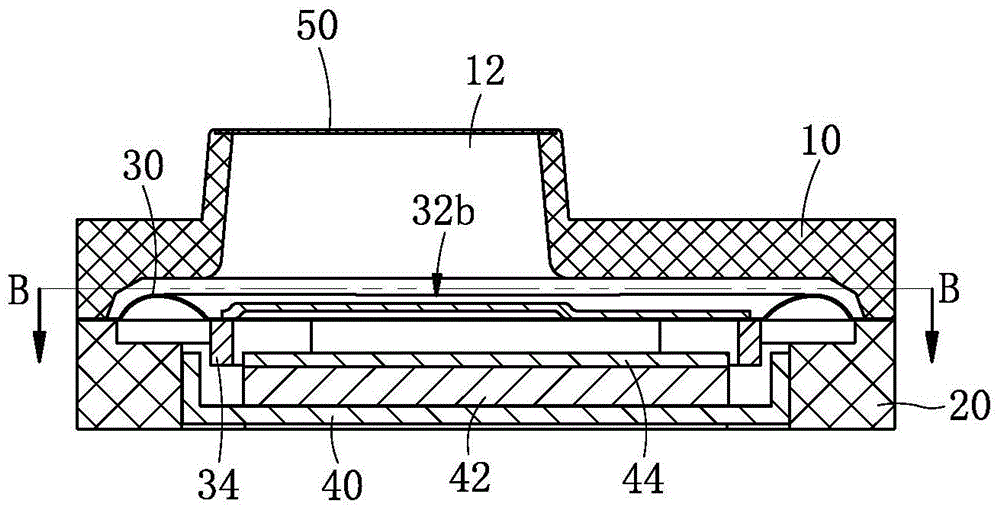

[0034] Such as image 3 and Figure 4 Commonly shown, the position corresponding to the orthographic projection area of the sound outlet 12 on the dome 32b is provided with a pressure regulating portion 320b, the pressure regulating portion 320b includes a central portion 322 of a planar structure, and the periphery of the central portion 322 is connected to the dome through a connecting portion 324. The other parts of 32b are joined together, and the connection part 324 is an approximately tapered annular slope structure.

[0035] The structure of the pressure regulating part is not limited to the structure described in the above two embodiments, it can also be a wave surface structure with a depression in the middle, as long as it can play the role of balancing the sound pressure of the front acoustic cavity.

[0036] In the present invention, the spherical dome is arranged as an asym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com