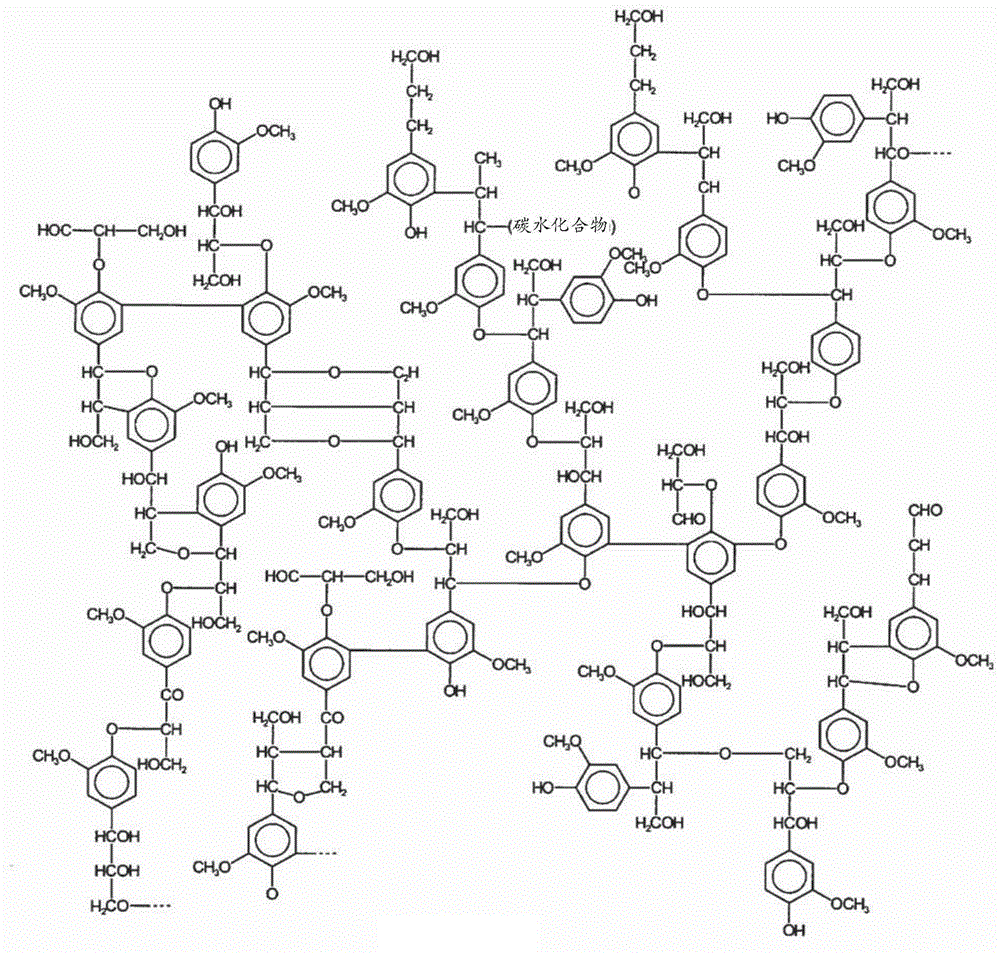

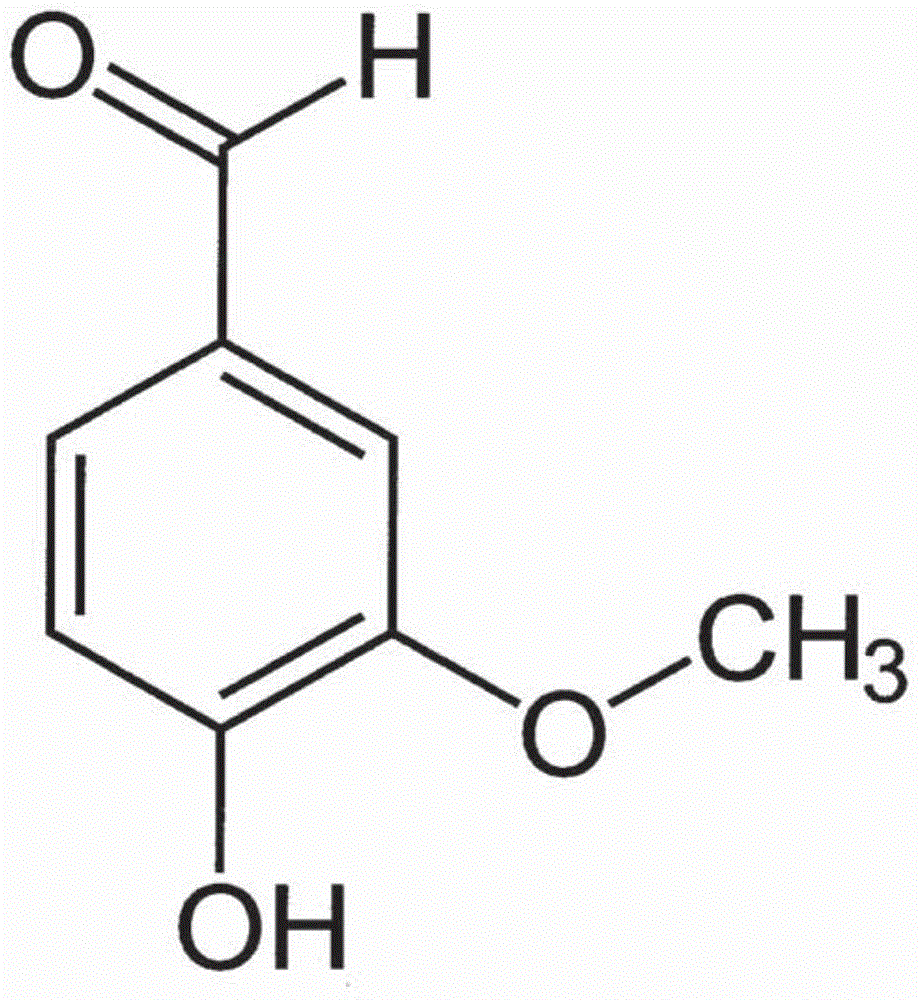

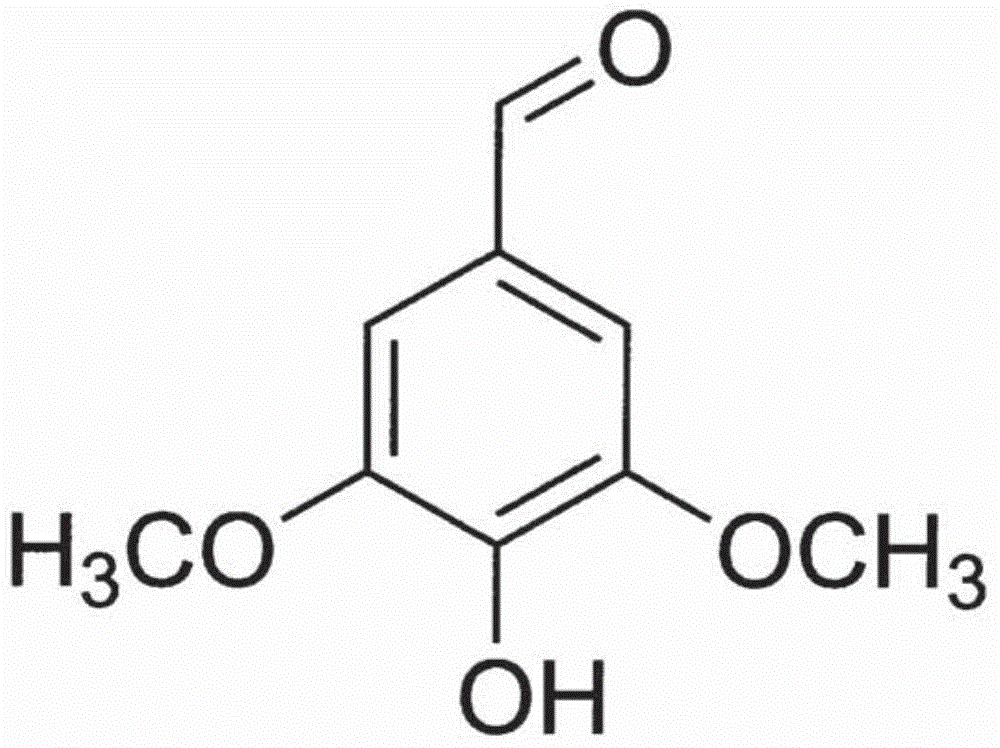

Catalysts for the mechanocatalytic oxidative depolymerization of polymer-containing materials and methods of making oxidized reaction products using same

A technology for oxidation catalysts and reaction products, applied in the preparation of organic compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve inappropriate, uneconomical environment, high consumption of strong alkali And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0058]As shown in Table 1 below, oxidation catalysis of lignin-containing materials with different oxidation catalysts was performed on SPEX 8000M (single) and SPEX 8000D (dual) mixing mills in Mitacheng, NJ (SPEX CertiPrep, Metuchen, NJ ) and agitation is provided by the mixer mill. Weigh enough oxidation catalyst and lignin-containing material (ie, Douglas fir chips) to produce a total mass of 1 gram. These ratios were varied to meet the ratios specified in Table 1. If no ratio is specified, the ratio is 1:1. The oxidation catalyst / lignin-containing material was placed in a flat bottomed SPEX mill vial with a volume of approximately 65 ml. Use three 1 / 2-inch steel ball bearings as the grinding media. Again, milling was performed in 8000M (single) and 8000D (dual) mixer / mills. Grinding vials, caps, and steel ball bearings are constructed from 440C stainless steel. All samples were milled for two hours.

[0059] A small amount of these oxidized reaction products (along w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com